Galvanized Steel Beams

Galvanized Steel Beams Related Searches

Galvanized Steel Pipes Galvanized Steel Piping Steel Galvanized Galvanized Tube Steel Galvanized Steel Panels Galvanized Steel Tube Galvanized Stainless Steel Galvanized Steel Tubs Galvanized Steel Wall Panels Weld Galvanized Steel Galvanized Steel Fencing Painted Galvanized Steel Galvanized Steel Grating Galvanized Steel Fence Panels Galvanized Steel Tank Galvanized Steel Roofing Panels Galvanized Steel Roof Galvanized Steel Shed Galvanized Steel Panel Galvanized Steel Siding Joining Steel Beams Galvanized Corrugated Steel Galvanised Iron Wire Galvanized Steel Raised Beds Galvanized Steel Square Tubing Galvanized Steel Paint Galvanized Steel Fence Galvanized Steel Planters Galvanized Steel Garden Beds Galvanized Steel EdgingGalvanized Steel Beams Supplier & Manufacturer from China

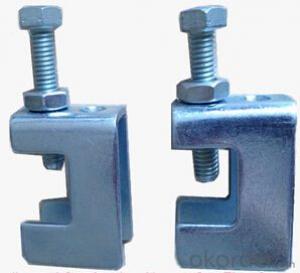

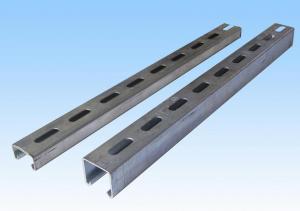

Galvanized Steel Beams are a type of structural steel that has been coated with a layer of zinc to provide enhanced corrosion resistance. These beams are commonly used in construction and engineering projects due to their durability and strength. They are ideal for applications where resistance to harsh weather conditions and environmental factors is crucial, such as in coastal areas or industrial settings.Galvanized Steel Beams are widely used in various construction and engineering projects, including bridges, buildings, and other infrastructure. They offer a cost-effective and reliable solution for supporting heavy loads and maintaining structural integrity. The zinc coating on these beams not only protects against rust and corrosion but also provides a sleek, aesthetically pleasing finish. This makes them suitable for both functional and decorative purposes, enhancing the visual appeal of any structure they are incorporated into.

Okorder.com is a leading wholesale supplier of Galvanized Steel Beams, offering a vast inventory of high-quality products to cater to the needs of various industries. With a commitment to providing exceptional customer service and competitive pricing, Okorder.com ensures that clients receive the best possible value for their investment in Galvanized Steel Beams.

Hot Products