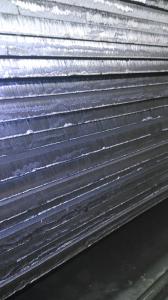

MS Galvanized Steel I Beam

- Loading Port:

- Tianjin,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 6000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Galvanized I beam

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 12m as following table

3. Connection of steel structure method: Welding, Bolted

Surface treatment: Painting, Galvanized

Roof &Wall System Sheet: colored steel tiles or colored steel sandwich panel per request

Doors: Roller or Common, as request

4. Quality standard

Certification: ISO9001:2000, SGS Standard

Code for design of steel structure: GB 50017-2003

Technical code of cold-formed thin-wall steel structure: GB50018-2002

Load code for the design of building structures. GB 50009-2006

Construction quality acceptance of steel: GB50205-2001

Code for design, construction and acceptance of high strength for steel structure, JGJ82-91

Technical specification for welding of steel structure building: JGJ 81-2002

Technical specification for steel Structures of tall buildings: (JGJ99-98)

Specifications for processing of steel structure: DBJ 08-216-1995

Specifications for design and construction of steel panel: YBJ 216-88

5.Size of MS Galvanized Steel I Beam

Style | Size | Theoretical Weight(kg/m) | Style | Size | Theoretical Weight(kg/m) |

10 | 100*68*4.5 | 11.261 | 32b | 32*132*11.5 | 57.741 |

12 | 120*74*5 | 13.987 | 32c | 320*134*13.5 | 62.765 |

14 | 140*80*5.5 | 16.890 | 36a | 360*136*10 | 60.037 |

16 | 160*88*6 | 20.513 | 36b | 360*138*12 | 65.689 |

18 | 180*94*6.5 | 24.143 | 36c | 360*140*14 | 71.341 |

20a | 200*100*7 | 27.929 | 40a | 400*142*10.5 | 67.598 |

20b | 200*102*9 | 31.069 | 40b | 400*144*12.5 | 73.878 |

22a | 220*110*7.5 | 33.070 | 40c | 400*146*14.5 | 80.158 |

22b | 220*112*9.5 | 36.524 | 45a | 450*150*11.5 | 80.420 |

25a | 250*116*8 | 38.105 | 45b | 450*152*13.5 | 87.485 |

25b | 250*118*10 | 42.030 | 45c | 450*154*15.5 | 94.55 |

28a | 280*122*8.5 | 43.492 | 56a | 560*166*12.5 | 106.316 |

28b | 280*124*10.5 | 47.888 | 56b | 560*168*14.5 | 115.108 |

30a | 300*126*9 | 48.084 | 56c | 560*170*16.5 | 123.900 |

30b | 300*128*11 | 52.794 | 63a | 630*176*13 | 121.407 |

30c | 300*130*13 | 57.504 | 63b | 630*178*15 | 131.298 |

32a | 320*130*9.5 | 52.717 | 63c | 630*180*17 | 141.189 |

Usage & Applications of Galvanized I beam

(1).used for the plant, high-rise building construction

(2).used for the bridge, shipment building

(3).used for lifting and transportation machinery, equipment manufacturing base building

(4).used for the support, foundation pile manufacturing

Packaging & Delivery of Galvanized I beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Galvanized I beam

Further performance and design information for galvanizing can be found in BS EN ISO 14713-1 AND BS EN ISO 14713-2. The durability performance of a galvanized coating depends solely on the corrosion rate of the environment in which it is placed. Corrosion rates for different environments can be found in BS EN ISO 14713-1 where typical corrosion rates are given with a description of the environment in which the steel would be used.

The process of hot-dip galvanizing results in a metallurgical bond between zinc and steel with a series of distinct iron-zinc alloys. The resulting coated steel can be used in much the same way as uncoated.

A typical hot-dip galvanizing line operates as follows:

Steel is cleaned using a caustic solution. This removes oil/grease, dirt, and paint.

The caustic cleaning solution is rinsed off.

The steel is pickled in an acidic solution to remove mill scale.

The pickling solution is rinsed off.

- Q: What does "M" mean?

- The former refers to the steel, round steel, flat steel, angle steel, six angle steel; the latter refers to the I-beam, channel steel, steel, steel, steel frame bending etc..

- Q: Does the profile include H?

- In addition, the profiles include: profile steel, including gear ring, horseshoe steel, pole steel, foot plate, shallow channel, small channel steel, T-shaped steel, ball flat steel, send steel, hot-rolled, six angles, etc.. There are also rivets, steel, farm tools, steel, window frames, steel. Cold bending, cold drawn steel and so on.

- Q: What does "BH" mean?

- In accordance with the different smelting quality of steel, steel is divided into ordinary steel and high quality steel. According to the current catalogue of metal products, ordinary steel can be divided into large section steel, medium section steel and small section steel. The section steel can be divided into I-beam, channel steel, angle steel, round steel and so on according to its sectional shape.

- Q: Elastic modulus of section steel

- The elastic modulus of steel is 2.1 * 10^7N/cm L.

- Q: What kind of steel is used in steel columns?

- At present, there are 3 kinds of steel pile commonly used in engineering construction, they are steel pipe column, steel column and steel sheet pile.

- Q: What is special steel?

- Plough steelUsed in the manufacture of general purpose plow, plows, shallow tillage implements main plough and ordinary before plow ploughshare, general wear and has sufficient strength and toughness of the steel. China's general use of 65Mn and 65SiMnXt steel. In addition, often make tools steel and special steel shape. Such as T steel, Z steel, arc type steel, double reinforcing steel, strengthen the font, grass blade steel, flat steel and steel rod concave lines. The cold-formed steel: cold-formed steel is the main material for the production of light steel structure, made of steel or steel roll forming. It not only the wall thickness can be made very thin, but also greatly simplifies the production process, improve production efficiency, can be produced using the general method to produce uniform wall thickness and complex cross sections of various shapes and different materials of cold-formed steel cold-formed steel. Except for the building structure, but also widely used In vehicle manufacturing, agricultural machinery and so on. A lot of cold-formed steel varieties, according to the opening section, semi closed, closed. According to the shape of a cold roll, angle steel, Z steel, square tube, rectangular tube, special pipe, shutter door according to the provisions of GB6725-92, cold-formed steel with ordinary carbon negative structure and quality carbon steel, low alloy steel plate or strip made of cold-formed structure

- Q: Can the section steel butt joint in the end?

- If welding, it is mainly worried that the welding is not strong and the welding stress is too large. The wall thickness of the section steel is thin, and the butt welding itself is the most unreliable. So, in the joint lining board, fillet welded. Attention is paid to reducing stress in the process.

- Q: What are the common types of profiled steel?

- Section steel is divided into two types: simple section steel and complex section steel.Simple section steel: steel, wire rod, square steel, flat steel, six angle steel, triangular, elliptical steel, steel arch steel, etc..

- Q: How to distinguish cold formed section steel and hot rolled section steel?

- The difference between cold-formed steel and welded steel tubes is that welded steel pipes are mainly used for conveying fluids, such as gas and tap water. Petroleum, liquefied petroleum gas, steam, etc. The steel tube is subjected to a certain amount of pressure, while the cold-formed steel is used to make the structure. Under the action of external force, the cold-formed steel is required for the section, shape, size and mechanical properties of the section steel.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2005 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Mid East; Southeast Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 5-10People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

MS Galvanized Steel I Beam

- Loading Port:

- Tianjin,China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 6000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords