Aluma Beam

Aluma Beam Related Searches

Aluma Beam Capacity Aluminium H Beam Aluminum T Beam H Beam Aluminium Beam Material Simple Beam Beam Launcher Waler Beam Lvl Beam Alumina Tube Beam 2100 Aluminum Angle Simple Beam Bridge Beam Joints L Beam Steel Alumina Ore Aluminum Strip Stainless Steel I Beam Aluminium Curtain Wall Angle Aluminum Aluminium Circle Aluminio Gofrado Aluminum Circle Hot Rolled H Beam Aluminum Grate Mesh Aluminium Coating Aluminium Square Tube Ulma Flanges Joining Steel Beams Aluminum GatesAluma Beam Supplier & Manufacturer from China

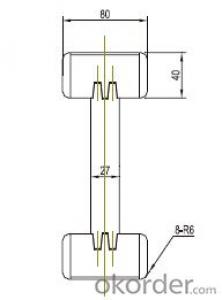

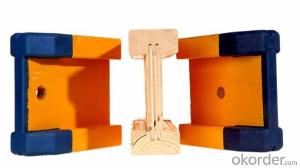

Aluma Beam is a line of high-quality aluminum extrusion products designed for various construction and industrial applications. These beams are known for their durability, lightweight, and corrosion resistance, making them ideal for use in a wide range of environments. They are commonly used in the construction of commercial buildings, bridges, and other infrastructure projects where strength and longevity are essential.Aluma Beam products are versatile and can be utilized in numerous scenarios, such as supporting roof structures, creating frameworks for walls and partitions, and serving as load-bearing components in various engineering projects. Their ease of installation and maintenance further enhance their appeal to contractors and engineers, who value efficiency and cost-effectiveness in their work.

Okorder.com is a reputable wholesale supplier of Aluma Beam products, boasting a vast inventory that caters to the diverse needs of customers across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that clients receive top-notch Aluma Beam products at competitive prices, making it a preferred choice for those seeking reliable and efficient aluminum extrusion solutions.