Beam Material

Beam Material Related Searches

Beam Joints Beam Launcher Simple Beam Sound Absorbing Material Noise Absorbing Material Aluma Beam L Beam Steel Simple Beam Bridge Beam 2100 Good Soundproofing Materials Joining Steel Beams Lvl Beam Stainless Steel I Beam Reinforcement Material H Beam Aluminium Aluminium H Beam Aluminum T Beam Aluma Beam Capacity Waler Beam Raw Material For Steel Inexpensive Soundproofing Materials Environmental Liners Iron Raw Material Structural Columns And Beams Cloth Material Fabric Bolting Steel Beams Together Furniture Packaging Materials Hot Rolled H Beam Containment Liners Bead TapeBeam Material Supplier & Manufacturer from China

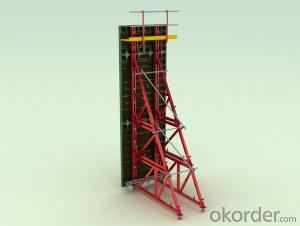

Beam Material encompasses a diverse range of products, including steel beams, aluminum beams, and wooden beams, which are designed to provide structural support in various construction and engineering projects. These materials are essential for creating strong and stable frameworks in buildings, bridges, and other infrastructures. The application and usage scenarios of Beam Material are vast, as they can be found in residential and commercial construction, industrial settings, and even in the creation of temporary structures for events and exhibitions. The versatility of these materials allows them to be tailored to specific project requirements, ensuring optimal performance and durability.Okorder.com is a leading wholesale supplier of Beam Material, offering a comprehensive inventory that caters to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Beam Material they provide meets the highest standards of performance and reliability. Their extensive inventory allows customers to find the perfect materials for their specific applications, whether it's for large-scale construction projects or smaller, more specialized tasks. By partnering with Okorder.com, customers can benefit from competitive pricing, efficient shipping, and the assurance that they are receiving top-quality Beam Material to support their projects.

Hot Products