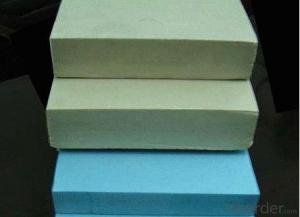

Sound Absorbing Material

Sound Absorbing Material Related Searches

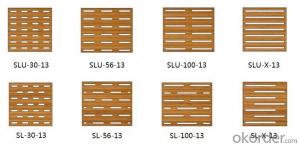

Noise Absorbing Material Good Soundproofing Materials Inexpensive Soundproofing Materials Soundproofing A Wall Soundproofing Homes Waterproof Material Soundproofing Floors Acoustic Padding For Walls Soundproofing A House Soundproof Curtains Roof Insulation Materials Soundproofing A Floor Light Roofing Materials Soundproofing Spray Foam Soundproofing Foam Spray Natural Insulation Materials Marine Insulation Material Bumper Materials Soundproof Foam Tiles Heat Reflective Material For Roof Reinforcement Material Acoustic Ceiling Solutions Car Bumper Materials Soundproofing Between Floors Organic Insulation Materials Pressure Sensitive Adhesive Tapes Sonic Barrier Acoustic Foam Synthetic Resin Material Contemporary Roofing Materials Soundproof Foam SpraySound Absorbing Material Supplier & Manufacturer from China

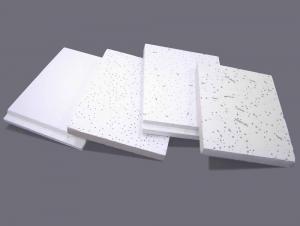

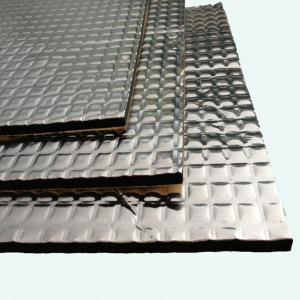

Sound Absorbing Material is a collection of various products designed to reduce noise levels by absorbing sound waves. These materials can be made from different substances such as foam, fiberglass, or mineral wool, and they are engineered to minimize echo and reverberation in various environments. The application of Sound Absorbing Material is extensive, as it is utilized in a wide range of settings to improve acoustics and reduce noise pollution. Common usage scenarios include offices, schools, recording studios, and auditoriums, where clear communication and sound quality are essential. By incorporating these materials into the design of these spaces, architects and acousticians can create more comfortable and productive environments for occupants.Okorder.com is a reputable wholesale supplier of Sound Absorbing Material, offering a vast inventory to cater to the needs of various industries and projects. With a commitment to quality and customer satisfaction, the company ensures that their products meet the highest standards for performance and durability. By providing a comprehensive selection of Sound Absorbing Material, Okorder.com enables customers to find the perfect solution for their specific requirements, whether it's for a small home studio or a large commercial building.

Hot Products