Fiberglass Wall Board Sound Absorption Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

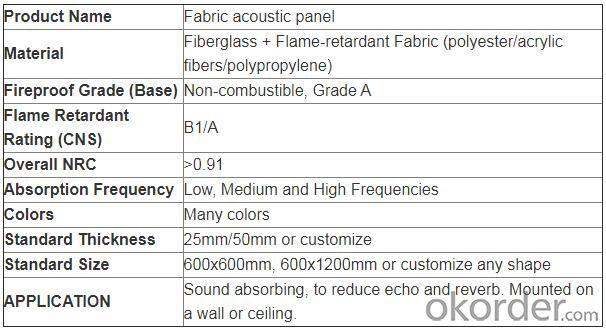

Specification

Description

Fiberglass acoustic panels are made of acoustic fiber and fabric or leather on surface, have excellent soundproof performance in both mid and high frequency. They are decorative and easy to installed. The fabrics on the surface are available in different colors and patterns. Customized is acceptable, you can also provide your own fabrics and designs.

Specification

Application

It is recommended that the Fiberglass Acoustic Wall Panels be installed to the opposite two walls to control the echo of the surroundings. The panels are widely used in Commercial Halls, Classrooms, Offices, Librairies, Shopping Centers, Music Rooms, Auditoriums, etc.where have special request for sound absorption.

Product Features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 4 weeks after receiving of downpayment

Picture

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q: How to do with glass fiber wall anti-crack

- For glass fiber is also used to see you are used in the external walls or interior walls, wall materials are different, a lot of things are not applicable once. Do not apply their own norms. And a slap to shoot the whole law

- Q: FRP can be used to make walls

- If the use of fiberglass do wall to see and what it is connected to the medium, or very easy to stratify, if it is in the cement surface to do the wall, I suggest you use epoxy resin, resin and sub-reinforced resin and food Grade resin, with food grade resin to do, no harm to the body, that is not food-grade, after curing the harm to the human body than other decorative materials damage small

- Q: What are the lightweight wallboard materials?

- Light wall material as a new type of product, technology is still in the process of the evening, this period inevitably there are some quality problems, affecting its promotion. In the long run, due to the wall material has embarked on a thin body, light, functional diversification (insulation, sound insulation) of the road of innovation, light wall panels will be developed as the country, as a wall material leading.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The partition board refers to the wall prefabricated slabs for the interior wall of the JG / T169-2005 "Building slabs for use with partitions". The partition panels contain glass fiber reinforced cement slabs, glass fiber reinforced Gypsum hollow slab, steel wire (steel mesh) reinforced cement slab, light concrete slats, composite sandwich light bar and so on. The full name is the construction of the wall with a light strip, as the usual industrial construction, residential construction, public construction of non-load-bearing wall of the main information.

- Q: What is GRC and can I paint it?

- GRC popular understanding of it, refers to the FRP to do the components of profiles. Can be made into any shape, such as sculpture, murals, decorative lines, etc., generally have a good finished product for you to choose. The advantage is high hardness and light weight and the price is not expensive. Is now a large number of decorative materials used. Can be based on your request, do oily or metallic paint, using the basic are spraying process. Another: custom need to open a separate mold costs, so if a small amount of custom, it is more expensive friends.

- Q: What is grc widget

- Now the domestic grc component manufacturers in the rising, but do a lot better to do a few, Guangzhou Shengfan building materials is one of them

- Q: Wall material that kind of environmental protection?

- Glass fiber wall cloth, that is, wall fabric, the function is relatively strong, it is made of glass fiber, not only environmentally friendly, and fire anti-cracking moisture, scrub resistance, good care, life of more than 10 years. Whether the project or home improvement is a good choice.

- Q: The difference between GRC lightweight partition board and ceramic plate

- Hello, the difference between the two is great GRC lightweight partition board: glass fiber reinforced cement to do the board; GRC has a thin structure, high resistance to stretch, good impact resistance, low alkalinity, free expansion rate of small crack performance and reliable, stable quality, moisture, , Non-combustible, sound insulation, can be sawed, drillable, can be nailed, can be shaved, can chisel, wall smooth construction Jane. Grc components are generally used in high-end villa exterior decoration or European-style building on the external walls of decoration. If the grc component of the type of large number of large Friends of the grc can be opened in the project next to a temporary plant to facilitate the construction of the late, grc components can be divided into color and gray.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The composite material is mainly composed of two parts: the reinforcing material and the base material: Reinforcing material: does not constitute a continuous phase in the composite material to the main mechanical properties of composite materials, such as fiberglass in the glass fiber, CFRP (carbon fiber reinforced plastic) in the carbon fiber is reinforced. A resin in a single material, such as glass fiber reinforced plastic (GRP), which constitutes a continuous phase of a composite material, is a matrix. Y

Send your message to us

Fiberglass Wall Board Sound Absorption Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches