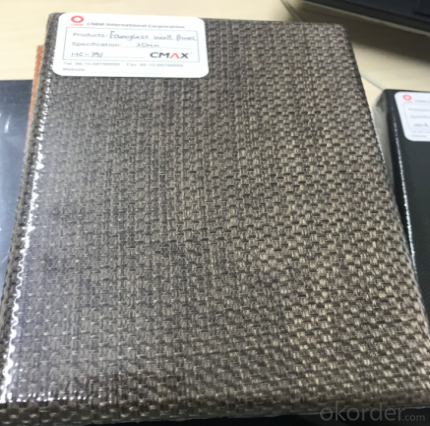

Fiberglass wall panel decoratice fabric acoustic board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass wall panel decoratice fabric acoustic board

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

CMAX

Ceiling Tile Shape:

Square

Ceiling Tile Type:

Fiberglass Ceilings

Product name:

fiberglass wall panelling for sale

Material:

Glass fiber

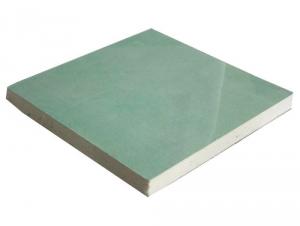

Standard size:

600*600 mm, 600*1200 mm, 600*1800 mm

Thickness:

12mm, 15mm, 20mm,25 mm

Advantage:

Heat/sound insulation, sound absorption, environmental protection

Application:

KTV, Hotel, Hanquet hall,Gymnasium, Multi-function

Packing:

15 PCS/CTN or as required

Certification:

ISO9001

MOQ:

100 sqm

Payment:

T/T, Trade assurance, L/C at sight,

Packaging & Delivery

Packaging Details

Packed in cartons for acoustic decorative fiberglass wall panelling for sale

Port

Shanghai, Qingdao,Lianyungang,Ningbo China

Lead Time :

15 days after deposit

Product Description

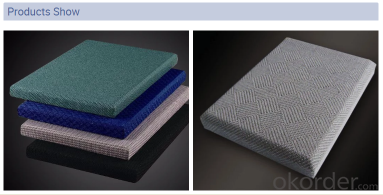

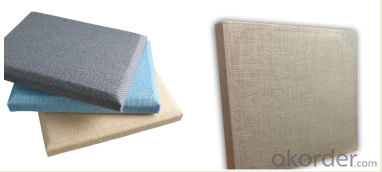

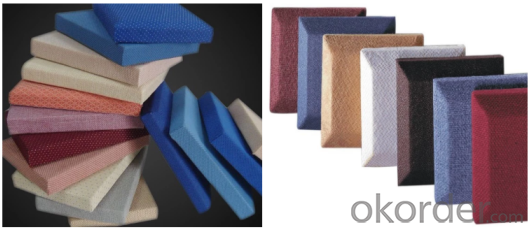

Acoustic Wall Panel Series

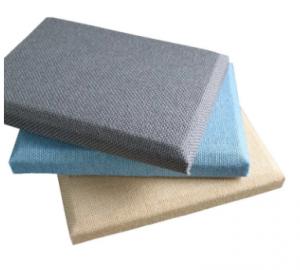

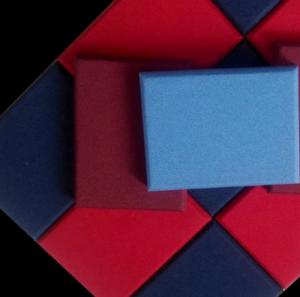

Soften space, constant temperature warm effect, the integration of decoration and whole frequency sound absorption. Optional colors and fabrics, meeting the varied acoustic and decorative requirement

Product Name | ISO certificate decorative fabric wrapped fiberglass acoustic wall panel |

Material | Glass fiber |

Frame | flame-retarded resin, wooden, aluminium |

Volume weight | ≥70~100 kg/m³ |

Fire performance | B1 |

Environmental performance | class E1 |

Thickness | 12 mm, 15 mm, 20 mm, 25 mm or 50 mm Customized |

Certification | ISO 9001, ISO 14000 |

Application | KTV, Hotel, Hanquet hall, Gymnasium, Multi-function room, Audio-video room, other acoustic required places |

Product features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

Packing & Delivery

Packing Details : Standard Package

Loading information for regular size:

Size | Thickness | Packing ( PCS /CTN ) | Quantity( 40 HQ ) |

600mm*600mm | 12 | 25 | 13300 PCS /532 CTNS /4788㎡ |

600 mm*1200mm | 12 | 25 | 6650 PCS /266 CTNS /4788㎡ |

600mm*600mm | 15 | 20 | 10640 PCS /532 CTNS /3830.4㎡ |

600 mm*1200mm | 15 | 20 | 5320 PCS /266 CTNS /3830.4㎡ |

600mm*600mm | 20 | 15 | 7980 PCS /532 CTNS /2872.8㎡ |

600 mm*1200mm | 20 | 15 | 3990 PCS /266 CTNS /2872.8㎡ |

600mm*600mm | 25 | 12 | 6384 PCS /532 CTNS /2298.2㎡ |

600 mm*1200mm | 25 | 12 | 3192 PCS /266 CTNS /2298.2㎡ |

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The first floor said yes. I feel it In the use of grid cloth at the same time you have to look at the quality of grid cloth.

- Q: FRP can be used to make walls

- FRP can be used to make walls. FRP Product Category: Glass cans, glass cans, hydrochloric acid storage tanks, sulfuric acid storage tanks, reaction tanks, preservative tanks, chemical storage tanks, transport tanks, food cans, fire cans, etc. Glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, glass fiber reinforced plastic pipe, Towers: drying tower, washing tower, desulfurization tower, acid mist purification tower, exchange column; Bathroom: bathroom chassis, bathroom roof.

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- Lightweight aggregate concrete partition board: is made of lightweight aggregate concrete slab, which is suitable for ordinary building grade. Lightweight aggregate concrete is made of natural light aggregate (such as pumice) or artificial light aggregate (such as ceramic) or industrial waste light aggregate (such as slag beads) plus cement and water mixed with concrete. Lightweight aggregate concrete and ordinary concrete is the difference between light aggregate concrete without stones, and some of his aggregate can float on the water.

- Q: What should the overall wardrobe design should have?

- The main features of the overall wardrobe are: standardized modules, tailor-made. The overall wardrobe according to the different styles can be divided into integral, into the wall, support and into the four categories. The overall design of the wardrobe and the pursuit of harmony with the home, in a warm atmosphere of life, bringing a simple and stylish charm, so that you poetic dwelling, artistic life. Therefore, the overall wardrobe style selection and design is essential:

- Q: What is grc widget

- Grc components, also known as grc, is a glass fiber reinforced cement composite material, the middle is empty, made by the two pieces of stitching, the components themselves have glass fiber, the characteristics of cement alkali resistance, divided into many kinds, There are grc relief, Guangyou grc lines, grc Roman column, grc window sets and so on.

- Q: Does the wall paint the shear wall need to hang the fibrous web?

- Fiber mesh, also known as reticular fiber, reticular polypropylene fiber, is a polypropylene as raw material, through a special process from manufacturing. The appearance of a number of fiber monofilament cross-linked from the network structure.

- Q: Wall material that kind of environmental protection?

- Diatom mud soft bag wallpaper floor wall is now a lot of latex paint is also very environmentally friendly

- Q: The difference between GRC lightweight partition board and ceramic plate

- A plate made of ceramsite concrete, usually a non - load - bearing wallboard.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production of glass fiber is "clay crucible method", "platinum on behalf of the crucible method", "pool kiln" three methods. "Clay crucible method" is the most primitive process, the main raw materials for the waste glass, the process of high energy consumption, poor product quality, is the state out of the prohibition of the process. "Platinum crucible method" is currently widely used in the process, the raw material for the glass ball. "Pool kiln" is the most advanced technology, its raw materials are "pyrophyllite" mainly mineral powder mixture.

- Q: Grc light partition board construction steps is what

- Partition board positioning, elastic line According to the construction drawings, in the installation of partition board, that is, the column side, ground, ceiling, beam bottom and the GRC light wall panels and other thickness of the two parallel ink line, and marked the door and window openings, Parallel to the side of the ink line 100mm pop up a parallel to the wall of the first three ink lines, as the inspection control line, after the installation of the partition to check the location of the partition is correct.

Send your message to us

Fiberglass wall panel decoratice fabric acoustic board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords