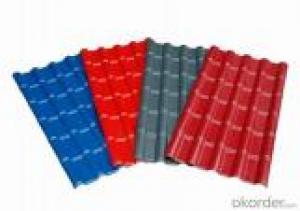

Fiberglass Sheets For Roofing

Fiberglass Sheets For Roofing Related Searches

Fiber Sheet For Roof Fiberglass Panels For Roofing House Roof Sheets Roofing Plywood Sheets Green Plastic Roofing Sheets Corrugated Shed Roof Sheets Fiberglass Roof Shingles Fitting Corrugated Plastic Roofing Sheets Fiberglass Roofing Tissue Flexible Plexiglass Sheets Fiberglass Patio Roof Corrugated Felt Roof Sheets Pp Roofing Sheets Felt Paper For Roofing Fiberglass Insulation Blanket Fiberglass Roving Fitting Polycarbonate Roofing Sheets Colour Roofing Sheet Buy Roofing Sheets Online Plastic Coated Steel Roofing Sheets Coroline Roofing Sheets Imitation Slate Roofing Sheets Fiberglass Wall Insulation Fiberglass Panels For Sale Fiberglass Blanket Insulation Fiberglass Roof Philippines Clear Perspex Roofing Sheets Fiber Roofing Sheets Price In Pakistan Fiberglass Thermal Insulation Fiberglass PropertiesFiberglass Sheets For Roofing Supplier & Manufacturer from China

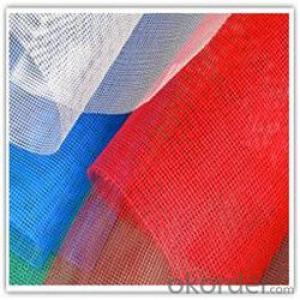

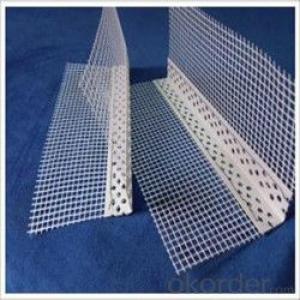

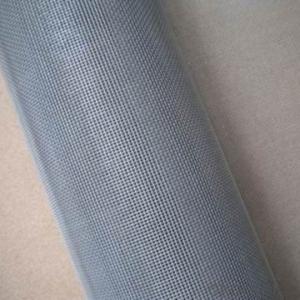

Fiberglass sheets for roofing are a popular choice for constructing durable and weather-resistant roofing systems. These sheets are made from a combination of glass fibers and synthetic resins, providing excellent strength and flexibility. They are known for their lightweight properties, ease of installation, and resistance to various environmental factors such as moisture, corrosion, and UV radiation.Fiberglass sheets for roofing are widely used in residential, commercial, and industrial buildings. They are particularly suitable for flat or low-sloped roofs, where their water-resistant properties help prevent leaks and damage. These sheets can also be used in combination with other roofing materials, such as metal or asphalt shingles, to create a hybrid roofing system that offers enhanced durability and energy efficiency. In addition to their practical benefits, fiberglass roofing sheets are available in various colors and finishes, allowing for a wide range of design options to suit any architectural style.

Okorder.com is a leading wholesale supplier of fiberglass sheets for roofing, offering a vast inventory of high-quality products at competitive prices. As a trusted source for construction materials, Okorder.com ensures that customers receive reliable and efficient service, with prompt delivery and excellent customer support. With a commitment to providing the best products and services, Okorder.com has become a go-to destination for contractors, builders, and homeowners seeking fiberglass sheets for roofing solutions.

Hot Products