Fiberglass Corrugated Roofing Sheet Used in Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

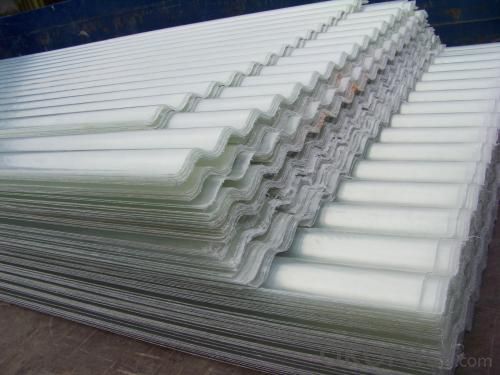

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

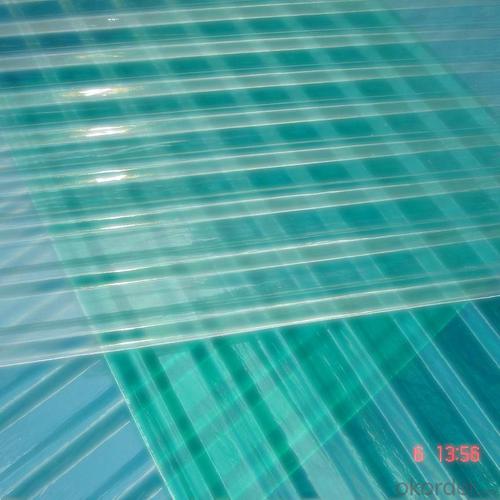

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATIONS

Composition | UP-resin system, glass fiber , gel coat or protective film |

Surface | Dupon 20um Film or Gel Coat |

Fiber Content | 25% - 35%, using JUSHI fiber |

Thickness | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm |

Width | Up to 1.35 meter |

Effective temperature | -40℃~ +120℃ |

Light Transmissivity | 3% - 85% |

Length | Customizable, for easy transport, suggest using 5.6m or 11.8m |

Profile | Flat type & corrugated type, LG840, LG900, LG1050 or customizable |

Colors | Clear blue, Light blue, Lake blue, Sky blue, Deep blue, Clear white, Solid white, Gray white, Black, Clear green or Customizable |

PICTURES

- Q: What are the advantages of using FRP roofing panels?

- Using FRP (Fiberglass Reinforced Plastic) roofing panels offers several benefits. To begin with, FRP roofing panels are renowned for their exceptional durability and longevity. They can withstand corrosion, UV rays, and even harsh weather conditions like hail, snow, and heavy rain. This makes them particularly suitable for regions prone to severe weather or high humidity. Moreover, FRP roofing panels are both lightweight and sturdy. As a result, they are easier to handle and install compared to alternative roofing materials. Additionally, their strength ensures that they can support heavy loads without cracking or breaking, making them suitable for residential and commercial purposes alike. Another advantage of FRP roofing panels lies in their versatility. They are available in a wide array of colors, textures, and profiles, providing numerous design options. They can even be manufactured to resemble other roofing materials such as shingles or tiles, thus offering an aesthetically pleasing appearance while retaining the benefits of FRP. Furthermore, FRP roofing panels boast excellent insulation properties. They can effectively regulate temperature, reducing energy consumption by keeping the interior of a building cooler in hot climates and warmer in cold climates. This can result in significant savings on heating and cooling expenses. Additionally, FRP roofing panels require minimal maintenance. They are easy to clean and need little upkeep throughout their lifespan. This saves both time and money compared to traditional roofing materials that may necessitate frequent repairs or replacements. Lastly, FRP roofing panels are environmentally friendly. They are crafted from recycled materials and can be recycled at the end of their lifespan. Moreover, their long lifespan reduces the need for frequent replacements, minimizing waste and environmental impact. In summary, the advantages of using FRP roofing panels encompass durability, strength, versatility, insulation properties, low maintenance, and environmental friendliness. These qualities make them an economical and practical choice for a variety of roofing applications.

- Q: Are FRP roofing panels resistant to discoloration from air pollution?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are highly resistant to discoloration caused by air pollution. The material's excellent resistance to UV radiation and chemical exposure makes it highly durable and less prone to fading or discoloration, ensuring a long-lasting and visually appealing appearance.

- Q: Can FRP roofing panels be used for green roofs with vegetation or gardens?

- Green roofs with vegetation or gardens can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess qualities of being lightweight, durable, and equipped with excellent weather resistance. As a result, they are well-suited to bear the weight of plants, soil, and water present on a green roof. Moreover, these panels are available in various thicknesses and can be tailored to meet the specific requirements of a green roof system. To construct a green roof with FRP panels, the first step involves installing a waterproofing membrane on the panels to prevent water leakage. Subsequently, a drainage layer is added to facilitate the drainage of excess water away. Following this, a filter fabric is placed on top to prevent soil from obstructing the drainage system. Once the foundational layers are established, a growing medium or soil mixture is incorporated to create an optimal environment for vegetation to flourish. Finally, the desired plants, grasses, or even small gardens can be planted on the green roof. It is imperative to acknowledge that meticulous planning and design are pivotal when utilizing FRP roofing panels for green roofs. Factors such as structural support, weight distribution, and drainage must be taken into account to ensure the long-lasting and functional nature of the green roof system. Consulting professionals experienced in green roof installation is strongly advised to guarantee a successful project.

- Q: Do FRP roofing panels require any special precautions during installation?

- Yes, FRP roofing panels require some special precautions during installation. It is important to handle the panels with care to avoid any damage. Additionally, proper safety measures should be followed, such as wearing protective gear and using appropriate tools. It is also crucial to ensure that the panels are properly aligned and securely fastened to prevent any leaks or structural issues.

- Q: Can FRP roofing panels be used in residential applications?

- Yes, FRP roofing panels can be used in residential applications. They offer durability, weather resistance, and are lightweight, making them suitable for various residential roofing needs.

- Q: Can FRP roofing panels be installed on wooden structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on wooden structures. FRP panels are lightweight and can be easily installed on various types of substrates, including wood. The key consideration when installing FRP panels on wooden structures is ensuring a proper installation process. This includes ensuring that the wooden structure is in good condition, free from any rot or damage, and providing adequate support for the panels. It is also important to follow the manufacturer's guidelines and recommendations for installation to ensure a secure and long-lasting installation. Overall, with proper installation techniques, FRP roofing panels can be successfully installed on wooden structures, providing a durable and weather-resistant roofing solution.

- Q: Can FRP roofing panels be installed over an existing roof?

- Yes, FRP roofing panels can be installed over an existing roof. However, there are a few factors that need to be considered before proceeding with this installation method. First, the existing roof should be structurally sound and able to support the weight of the FRP panels. Additionally, any existing leaks or damage should be repaired before installing the new panels. It is also important to ensure proper insulation and ventilation to prevent condensation and moisture buildup between the existing roof and the FRP panels. Lastly, it is recommended to consult with a professional roofing contractor who has experience with FRP installations to ensure the best results and adherence to local building codes and regulations.

- Q: Are FRP roofing panels prone to warping from heavy machinery?

- Yes, FRP roofing panels are prone to warping from heavy machinery. The weight and vibrations produced by heavy machinery can put significant stress on the panels, causing them to warp over time. It is important to consider the load-bearing capacity and installation guidelines of FRP roofing panels to minimize the risk of warping in such scenarios.

- Q: Can FRP roofing panels be used for skylights or translucent applications?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for skylights or translucent applications. FRP panels are known for their excellent light transmission properties, making them suitable for allowing natural light to enter a building. They are also highly durable and resistant to weathering, making them a reliable option for skylights or translucent applications that require protection from the elements. Additionally, FRP panels can be customized to meet specific design requirements, allowing for a versatile and aesthetically pleasing solution for skylights or translucent applications.

- Q: Can FRP roofing panels be used for covered walkways or breezeways?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be effectively used for covered walkways or breezeways. FRP panels are lightweight, durable, and resistant to corrosion, making them suitable for outdoor applications. They provide protection from the elements while allowing natural light to pass through, creating a pleasant and functional environment for pedestrians. Additionally, FRP panels can be easily installed and maintained, making them a practical choice for covered walkways or breezeways.

Send your message to us

Fiberglass Corrugated Roofing Sheet Used in Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords