FRP Roofing Panel S10

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 1000m2/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of FRP Roofing Panel S10

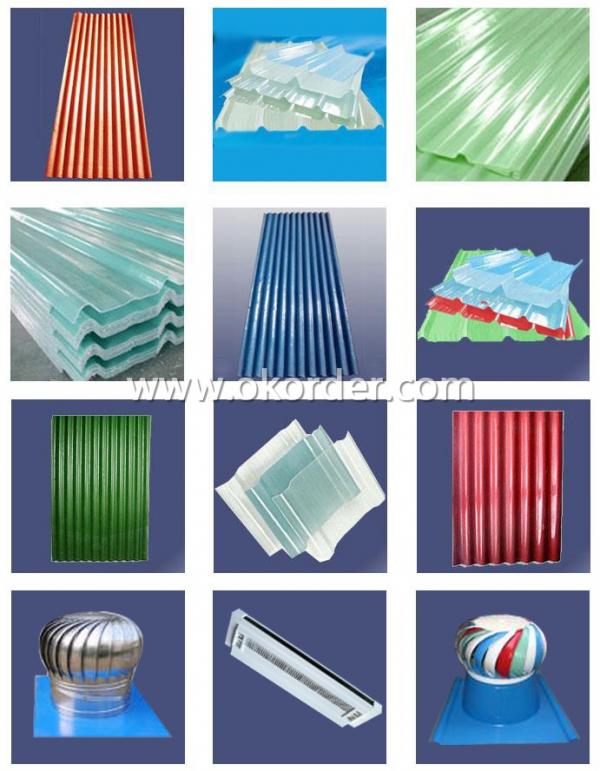

Thickness:1.0mm Color:sky blue, dark blue, clear, light green, dark green, opal, etc.Ordinary Wave: 840-210

Length:No limit but with the consideration of transportation

Introduction of FRP Roofing Panel S10

As HIGOAL's core product,FRP plastic sheet , Roof translucent panel, roof skylight ,sky roofing has been produced for over 14 years and has experienced many improvements which is an excellent lighting materials of steel building, New generation strengthened skylight sheet.

Brief Description of FRP Roofing Panel S10:

1). Anti-aging resin, longer duration of use.

2). Strong UV protection

3). High light transmittance

4). Less bubbles, good impact strength and flexural strength to withstand typhoons and hail hit.

5). Good Performance of film, flat and smooth. Dust is easy to be removed.

6). High-quality E-glass fibers, good light transmittance and water resistance

7). Good corrosion resistance, suitable for acid and alkali environment.

8). Even thickness, consistent mechanical properties.

Features of FRP Roofing Panel S10 :

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable

for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

- Q: Can FRP roofing panels be used for storage sheds?

- Certainly, storage sheds can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess the qualities of being lightweight, robust, and resistant to weathering, rendering them an outstanding selection for outdoor structures such as storage sheds. They deliver exceptional safeguarding against UV rays, moisture, and extreme temperatures, thus assuring the preservation of the shed's contents. Moreover, the installation and upkeep of FRP panels are hassle-free, making them a cost-efficient and pragmatic roofing alternative for storage sheds.

- Q: Can FRP roofing panels be used in modular construction?

- Modular construction can benefit from the utilization of FRP roofing panels. FRP, otherwise known as Fiber Reinforced Polymer, is a resilient and sturdy material frequently employed in construction due to its lightweight composition and resistance to corrosion and weathering. In the realm of modular construction, where buildings are constructed off-site in sections or modules and subsequently transported for assembly at the final location, the incorporation of FRP roofing panels can present several advantages. Firstly, the lightweight nature of FRP panels facilitates their handling and transportation, thereby contributing to the efficiency of modular construction. Moreover, FRP roofing panels offer exceptional insulation properties, thereby aiding in temperature regulation and reducing energy consumption within modular buildings. This is particularly advantageous in modular construction, where the maintenance of energy efficiency is crucial to sustainable and cost-effective building practices. Furthermore, FRP roofing panels exhibit high resistance to inclement weather, enduring extreme temperatures, UV rays, and moisture. This renders them a dependable choice for modular construction, particularly during transportation and assembly, when the durability of building materials is of utmost importance. Lastly, FRP roofing panels provide design flexibility, as they can be manufactured in a variety of colors, finishes, and profiles to align with the aesthetic requirements of the modular construction project. In summary, the lightweight composition, insulation properties, durability, and design flexibility of FRP roofing panels make them an ideal choice for modular construction. Their integration enhances the efficiency, sustainability, and aesthetics of modular buildings.

- Q: Can FRP roofing panels be used for museums?

- Yes, FRP roofing panels can be used for museums. FRP (Fiberglass Reinforced Plastic) roofing panels offer several advantages such as durability, flexibility, and resistance to corrosion, making them suitable for protecting valuable artifacts and exhibits in museums. Additionally, FRP panels can provide natural lighting and UV protection, creating a conducive environment for showcasing artwork and preserving historical items.

- Q: Are FRP roofing panels resistant to high winds?

- FRP roofing panels are known for their resistance to high winds. They possess strength and durability that enables them to withstand strong winds without any damage or being blown away. The inclusion of fiberglass reinforcement in the panels adds extra stiffness and strength, enhancing their ability to resist wind uplift. In addition, proper fastening systems like screws or clips are commonly used during the installation of FRP panels to firmly secure them to the structure. This further enhances their resistance to high winds. However, it is important to understand that the wind resistance of FRP roofing panels may vary depending on factors such as panel thickness, installation method, and specific wind load requirements outlined in the building code of the area. Therefore, it is advisable to consult the manufacturer or a roofing professional to ensure that the chosen FRP panels are suitable for the wind conditions specific to the installation location.

- Q: Are FRP roofing panels suitable for animal shelters or kennels?

- Yes, FRP roofing panels are suitable for animal shelters or kennels. FRP panels offer several advantages such as durability, resistance to corrosion, easy installation, and low maintenance. Additionally, they are waterproof, which is crucial to protect animals from rain and other weather elements. The panels also provide good insulation, ensuring a comfortable environment for the animals. Overall, FRP roofing panels are an excellent choice for animal shelters or kennels due to their durability and practicality.

- Q: Are FRP roofing panels suitable for historical buildings?

- Determining the appropriateness of FRP roofing panels for historical buildings relies on a few factors. Firstly, it is crucial to take into account the specific requirements and guidelines for conserving historical structures in the given area. Some preservation societies or organizations may have stringent regulations regarding the utilization of certain materials, including roofing materials. Thus, consulting with local authorities or historical preservation experts is necessary to ensure compliance with any restrictions. Secondly, the evaluation of the historical building's condition and its roofing system is essential. If the existing roof is significantly damaged or deteriorated, replacing it with FRP roofing panels could be a viable choice. The lightweight nature of FRP panels can reduce the burden on the structure, potentially minimizing the need for additional structural reinforcements. Moreover, FRP roofing panels offer several advantages that can benefit historical buildings. They possess a high resistance to corrosion, UV rays, and chemicals, ensuring durability and longevity. This is particularly advantageous for historical buildings exposed to harsh weather conditions or situated near industrial areas. Furthermore, FRP panels can be designed to imitate traditional roofing materials, such as clay tiles or slate, thus preserving the aesthetic allure of the historical building. They are available in various colors, textures, and profiles, allowing for customization to suit the architectural style of the structure. Nevertheless, it is essential to consider the potential impact of utilizing FRP panels on the overall visual appearance and authenticity of the historical building. Some preservationists argue that using modern materials like FRP may compromise the historical integrity and character of the structure. In such cases, alternative roofing materials that closely resemble the original ones may be preferred. In conclusion, the suitability of FRP roofing panels for historical buildings relies on various factors, including local regulations, the building's condition, and preservation objectives. Consulting with historical preservation experts and considering the building's specific needs can help determine if FRP panels are a suitable option.

- Q: What is FRP roofing panel?

- FRP roofing panels, also referred to as fiberglass reinforced plastic roofing panels, consist of a combination of fiberglass and plastic resin and are utilized as a type of roofing material. These panels possess attributes such as lightweightness, durability, and exceptional resistance to corrosion, chemicals, and weathering. Within industrial and commercial buildings, where strength and durability are crucial, FRP roofing panels find common application. They are frequently employed in facilities such as warehouses, factories, agricultural buildings, and sports facilities. One of the primary advantages of FRP roofing panels lies in their high strength-to-weight ratio, enabling them to offer a robust and dependable roofing solution while remaining lightweight and easy to install. Furthermore, an assortment of colors and finishes are available for customization, ensuring that the aesthetic requirements of a building are met. In addition, FRP roofing panels offer exceptional thermal insulation properties, contributing to temperature regulation within a building and reducing energy costs. With good light transmission capabilities, these panels allow natural light to permeate the building, thereby diminishing the need for artificial lighting during daylight hours. To summarize, FRP roofing panels are a versatile and enduring roofing material widely deployed in industrial and commercial settings. They deliver strength, resistance to corrosion and weathering, thermal insulation, and light transmission, making them a favored choice for various construction projects.

- Q: What is the insulation value of FRP roofing panels?

- The insulation value of FRP (Fiberglass Reinforced Plastic) roofing panels can vary depending on the specific type and thickness of the panel. However, FRP roofing panels generally have a lower insulation value compared to other roofing materials such as foam or metal panels. The insulation value is typically measured in terms of R-value, which indicates the resistance to heat flow. FRP panels typically have an R-value between 2 and 3 per inch of thickness, which means they provide some level of insulation but may not be as effective as other materials in terms of thermal performance. It is important to consider other factors such as climate, building design, and additional insulation measures when evaluating the overall insulation properties of FRP roofing panels.

- Q: Can FRP roofing panels be used for hotels?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for hotels. FRP roofing panels are known for their durability, strength, and resistance to various weather conditions. These panels are lightweight, easy to install, and require minimal maintenance. Additionally, FRP roofing panels offer excellent insulation properties, which can help in reducing energy costs for hotels. Moreover, FRP panels are available in a variety of colors, textures, and designs, allowing hotels to achieve the desired aesthetic appeal. Overall, FRP roofing panels are a suitable choice for hotels due to their durability, low maintenance requirements, energy efficiency, and versatility in design options.

- Q: Are FRP roofing panels suitable for buildings in coastal areas?

- When considering roofing options for coastal areas, FRP (Fiberglass Reinforced Plastic) panels may be a viable choice. These panels are renowned for their durability, strength, and ability to resist corrosion, making them well-suited for environments with saltwater and high humidity. Nevertheless, it is crucial to select top-notch FRP panels specifically designed for coastal regions. One of the primary advantages of FRP roofing panels in coastal areas lies in their corrosion resistance. Unlike traditional roofing materials such as metal, which can easily rust in salty environments, FRP panels are impervious to saltwater, rendering them ideal for coastal buildings. Moreover, FRP panels boast exceptional UV resistance, a critical feature in areas with intense sun exposure. Another factor to contemplate is the wind load. Coastal regions often experience strong winds and even hurricanes, necessitating the selection of FRP panels that meet the requisite wind load requirements. To ensure the panels can withstand high winds and adequately safeguard the building, reinforced FRP panels with additional support structures may be necessary. Additionally, the aesthetics of FRP roofing panels in coastal areas should be taken into account. While FRP panels are available in various colors and finishes, their appearance may not harmonize with all architectural styles or individual preferences. In such instances, alternative roofing materials that mimic the look of traditional materials may prove to be a better option. Lastly, regular maintenance is vital for the longevity of FRP roofing panels in coastal areas. Despite their resistance to corrosion, gradual wear and tear can still occur due to salt and humidity. To prevent any damage or degradation and ensure optimal performance, regular cleaning and inspection are imperative. In conclusion, FRP roofing panels can be a suitable choice for buildings in coastal areas due to their corrosion resistance, strength, and UV resistance. However, it is essential to select high-quality panels designed for coastal environments, consider wind load requirements, and perform regular maintenance to ensure their longevity and effectiveness.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 300,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Roofing Panel S10

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 1000m2/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords