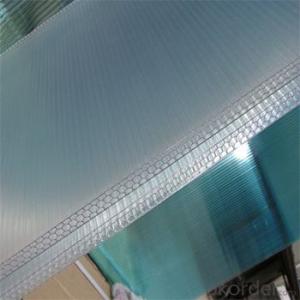

Corrigated Plastic Roofing

Corrigated Plastic Roofing Related Searches

Clear Corrugated Plastic Roofing Corrugated Polycarbonate Roofing Wavy Plastic Roofing Corrugated Plexiglass Roofing Polycarbonate Corrugated Roofing Solid Polycarbonate Roofing Fitting Corrugated Plastic Roofing Sheets Plastic Coated Steel Roofing Sheets Asphaltic Roofing Corrugated Plastic Siding Roof Polycarbonate Synthetic Felt Roofing Green Plastic Roofing Sheets Contemporary Roofing Materials Rigid Plastic Netting Heavy Duty Plastic Floor Covering Conservatory Plastic Roof Panels Spray Foam Roofing Polycarbonate Sheet Roofing Scaffolding Roof Silicone Roof Coating Industrial Roofing Protective Plastic Sheeting Light Roofing Materials Collapsible Scaffolding Commercial Roofing Materials Synthetic Slate Roofing Interstate Roofing Commercial Roofing Systems Galvanized Steel RoofCorrigated Plastic Roofing Supplier & Manufacturer from China

Corrigated Plastic Roofing is a type of roofing material that has gained popularity due to its durability, cost-effectiveness, and ease of installation. This product is specifically designed to provide protection against various weather conditions, making it an ideal choice for both residential and commercial buildings. The corrugated pattern on the plastic sheets enhances the strength and rigidity, ensuring long-lasting performance.Corrigated Plastic Roofing is widely used in a variety of applications, including sheds, garages, carports, and agricultural buildings. Its lightweight nature and resistance to corrosion make it a preferred choice for many construction projects. The product is also known for its energy efficiency, as it helps to maintain a comfortable temperature inside the building by reflecting sunlight and preventing heat transfer.

Okorder.com is a leading wholesale supplier of Corrigated Plastic Roofing, offering a vast inventory to cater to the needs of various customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products are sourced from reliable manufacturers and are available at competitive prices. This makes it an ideal platform for contractors, builders, and homeowners looking to purchase high-quality Corrigated Plastic Roofing for their projects.

Hot Products