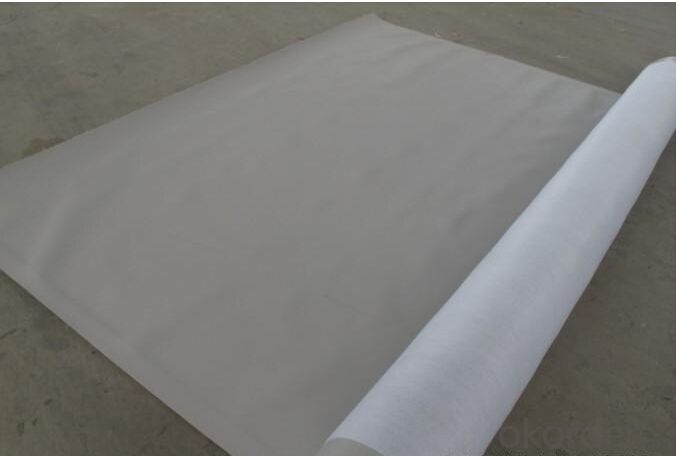

PVC Roofing and Waterproofing Plastic Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Waterproof Membrane

PVC waterproofing roofing membrane are based upon Polyvinyl Chloride Resin with other additives to provide flexibility and stability. It gives a good performance of anti-oxidant, absorbent of ultraviolet light, plasticizer, anti-UV agent, anti-aging with other additives to provide flexibility and stability. It gives a good performance of anti-oxidant, absorbent of ultraviolet light, plasticizer and plastic filling agent.

It is an excellent high quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti-aging agent, and stabilizer and other processing aids through extrusion and molding.

As the highly recommended product by the Ministry of Consturction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low temperature performances, good resistance to weathering and root penetration and long service life.

.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Advantage of PVC Waterproof Membrane

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Application of PVC Waterproof Membrane

PVC membrane applies special formula and its service life is much longer than other general waterproof membranes. Its excellent performance makes it be widely used in every field.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q:DTM.E polyester composite waterproofing membrane, cheaper than the asphalt membrane?

- Ouwei Jianke DTM.E polyester composite waterproofing membrane is the company according to GB50207-2002 "roofing quality acceptance norms", GB50108-2008 "underground engineering waterproof technical specifications", GB50208-2002 "underground waterproofing project quality acceptance norms" and Other waterproof engineering design Widely used in a new type of waterproof material,

- Q:Can a waterproofing membrane be used in interior or exterior applications?

- A waterproofing membrane can be utilized in both interior and exterior scenarios. When used indoors, such as in basements or bathrooms, the membrane can be applied to walls or floors to effectively prevent water or moisture infiltration. This safeguard shields the underlying structure from potential harm caused by water intrusion. For exterior applications, the waterproofing membrane can be employed on the outer walls or foundations of a building to effectively repel water. This becomes particularly crucial in regions with heavy rainfall or high water tables. By creating a barrier against water, the membrane effectively maintains a dry and water-free interior environment for the building. In conclusion, the utilization of a waterproofing membrane in both interior and exterior contexts is absolutely necessary in order to ensure the longevity and durability of a structure by effectively safeguarding it against water-related issues.

- Q:Can a waterproofing membrane be used for a parking garage deck protection?

- Indeed, the utilization of a waterproofing membrane is a viable option for safeguarding the parking garage deck. Designed with the specific purpose of preventing water infiltration and shielding the underlying structure from moisture-related harm, a waterproofing membrane proves to be highly effective in such scenarios. When applied to the parking garage deck, the waterproofing membrane acts as a barrier, effectively preventing water from permeating the concrete and reaching the steel reinforcement beneath. This, in turn, mitigates the risk of corrosion and deterioration, ultimately prolonging the lifespan of the structure and minimizing the need for expensive repairs or replacements. Moreover, the waterproofing membrane offers protection against other potential sources of damage, including oil or chemical spills resulting from vehicular activity. By creating a barrier, it successfully hinders these substances from penetrating the concrete and causing unsightly stains or deterioration. Supplementary to its protective capabilities, the waterproofing membrane enhances the overall durability and strength of the parking garage deck. It aids in the reduction of cracking, spalling, and other forms of concrete damage that may arise due to freeze-thaw cycles, temperature fluctuations, or heavy loads. All in all, opting for a waterproofing membrane to safeguard the parking garage deck is a highly recommended solution for ensuring the longevity and structural integrity of the facility. By providing a dependable defense against water infiltration, chemical spills, and other potential sources of damage, it serves to decrease maintenance expenses and extend the lifespan of the parking garage deck.

- Q:Is a waterproofing membrane compatible with different types of flooring materials?

- Yes, a waterproofing membrane is compatible with different types of flooring materials. A waterproofing membrane is designed to create a barrier between the subfloor and the flooring material, preventing moisture from seeping through and causing damage. This makes it suitable for use with various flooring types such as laminate, vinyl, tile, and even hardwood. The waterproofing membrane ensures that the flooring material remains protected from water damage, extending its lifespan and maintaining its appearance. However, it is important to note that different types of waterproofing membranes may have specific compatibility requirements, so it is recommended to consult the manufacturer's guidelines to ensure proper installation with the chosen flooring material.

- Q:Can a waterproofing membrane be used in conjunction with tile or stone installations?

- Yes, a waterproofing membrane can be used in conjunction with tile or stone installations.

- Q:Are waterproofing membranes resistant to high temperatures?

- Waterproofing membranes can vary in their resistance to high temperatures depending on the specific material used. Some waterproofing membranes are designed to withstand high temperatures without losing their effectiveness or integrity. These membranes are often made from materials such as modified bitumen or synthetic rubber, which have high temperature resistance properties. However, it is important to note that not all waterproofing membranes are resistant to high temperatures. Some membranes made from PVC or other thermoplastic materials may have limitations when exposed to extreme heat. Therefore, it is crucial to consult the manufacturer's specifications and guidelines to ensure that the chosen waterproofing membrane is suitable for the intended application and can withstand the anticipated temperature conditions.

- Q:Are waterproofing membranes suitable for tunnels?

- Yes, waterproofing membranes are suitable for tunnels. Tunnels are often subjected to high water pressure from the surrounding soil and groundwater, making them vulnerable to water ingress. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively prevent water from entering the tunnel structure. These membranes are typically made of durable materials such as bitumen, PVC, or EPDM rubber, which are resistant to water penetration. They are applied to the tunnel walls and ceiling to create a continuous, impermeable layer that keeps the tunnel dry. The membranes are also flexible, allowing them to accommodate any movement or settlement of the tunnel without compromising their waterproofing integrity. In addition to preventing water infiltration, waterproofing membranes also offer other benefits for tunnels. They can protect the tunnel structure from corrosion caused by water and chemicals, prolonging its lifespan. They can also help to improve the indoor air quality within the tunnel by preventing the growth of mold and mildew, which thrive in damp environments. Furthermore, waterproofing membranes can be customized to suit different tunnel conditions. For example, in tunnels that are exposed to high levels of hydrostatic pressure, reinforced membranes with higher tensile strength can be used to withstand the added stress. Additionally, membranes with enhanced fire resistance properties can be utilized in tunnels where fire safety is a concern. Overall, waterproofing membranes are a reliable and effective solution for ensuring the durability, safety, and longevity of tunnels by providing a robust barrier against water ingress.

- Q:Can a waterproofing membrane be used for roofs with foot traffic?

- Yes, a waterproofing membrane can be used for roofs with foot traffic. However, it is important to choose a membrane that is specifically designed and rated for foot traffic. These membranes are typically made with more durable materials, such as reinforced PVC or modified bitumen, to withstand the wear and tear caused by regular foot traffic. Additionally, it is crucial to ensure that the membrane is properly installed and maintained to prevent any damage or leaks that could compromise the waterproofing capability. Regular inspections and necessary repairs should be carried out to ensure the longevity and effectiveness of the membrane.

- Q:Can a waterproofing membrane be used in tunnels?

- Indeed, tunnels can indeed employ a waterproofing membrane. These membranes are frequently utilized in tunnels to thwart water infiltration and safeguard the structure from water-related harm. Generally composed of materials like bitumen, PVC, or polyurethane, these membranes possess impermeability to water as a core characteristic. When properly applied, a waterproofing membrane can act as a formidable barrier against water infiltration, thereby preserving the tunnel's integrity and avoiding expensive structural impairment. Furthermore, apart from their water-resistant properties, waterproofing membranes also provide defense against other substances like chemicals and gases, rendering them a versatile remedy for both tunnel construction and upkeep.

- Q:Does a waterproofing membrane require any maintenance or regular inspections?

- Yes, a waterproofing membrane does require regular maintenance and inspections. Over time, the membrane can become damaged or deteriorate, leading to leaks or other issues. Regular inspections help identify any potential problems early on and allow for timely repairs or replacements. Additionally, periodic maintenance such as cleaning and resealing may be necessary to ensure the membrane's effectiveness and longevity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Roofing and Waterproofing Plastic Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords