Herringbone Wooden Flooring 12mm European Oak E0

- Supplier:

BNBM Group Forest Products Co., Ltd.

BNBM Group Forest Products Co., Ltd.

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We have Four kinds of Wooden flooring, as below:

1.Multilayer Engineered Wooden Flooring,

Standard Size | Thickness: 15/4.0mm, 14/3.0mm, 12/2.0mm, 12/1.2mm, Width: 190mm, 220mm, 240mm, 165mm, 127mm, Length: 1900mm, 2200mm, 1210mm,

|

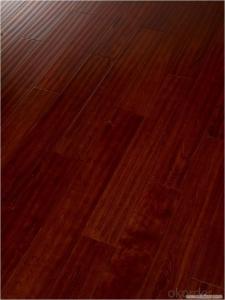

2.Herringbone Wooden Flooring

Standard Size | Thickness: 12/2.0mm, 12/1.2mm, 9.5/1.2mm; Width: 120mm, 90mm, 60mm; Length: 600mm, 900mm;

|

3.Three Layer Engineered Wooden Flooring

Standard Size | Thickness: 15/4.0mm, 14/3.0mm; Width: 190mm/220mm/240mm; Length: 1900mm/2200mm;

|

4.Shape Parquet Flooring

As request.

Production and Core:

- Q: We have a mess here =(. Got home to find our water heater broke. The waterheater is in between 2 rooms, one our office with engineered wood cherry floorsthey click together and have a pad underneath, and brand new carpeting in the otherroom that smells already is is soaked near the doorway.This is what we've done so far. Pulled the wood floors out. Most look WET, some are just kindawet.. were going to pull the padding out and replace it with new padding but is there anything we can do to save the wood, blowdry, fan??? Something help please.Carpet?

- Basically you're screwed, a little water is not a problem, a flood like that is a catastrophe, the floor will never be the same. The problem is getting the under-layment to dry, basically you can't so the moisture works from the bottom up. If you own the home your insurance will pay to replace it. You do have insurance don't you?

- Q: Can engineered wood flooring be installed on vinyl flooring?I'm in the middle of home improvement project and have decided to lay some engineered wood flooring for my kitchen. The particular brand that I've bought requires glue-down installation.The problem is, there's vinyl flooring that's been laid with cutback and it's not going to come up without a significant amount of work and then re-preparation of the sub flooring. I've been to the local home improvement center several times and can't really get a straight answer as to if this is possible. I've searched the Internet and its about 50-50 yes and no. I'd really like anybody's input into my situation, as I am under a little bit of a time constraint to finish the project as this is my new house and I've got to move out of my old house in in a week.Thanks in advance to your answers!

- If you are laying down Bruce or Armstrong flooring, they have instructions for laying over vinyl flooring. Basically you can't lay the flooring over more than 2 layers of vinyl. You want to make sure the flooring is stripped, not sanded, especially if there is a gloss on the floor. Don't sand if its a resilient floor, it may contain asbestos. Also they recommend specific adhesives that will bond with the floor.

- Q: Had engineered wood floors installed -- need to find safe products for it -- box only says Timberland.?

- look at the floor cleaner label, one will say its for laminate, one will say for polyurethane floors and another will say its for wax floors. Use cleaners that are for laminate floors or for wood floors, just dont wet mop laminate as it will permanently damage the floor. Swifters leave residues that are bad for pets and babies.

- Q: Good evening. I'm currently having a contractor install engineered hardwood on my steps. I have 3 planks that are 3/8 think. He is in the middle of construction now.

- Engineered Hardwood Stairs

- Q: Buy the 2 room, the floor is damaged, the master musicians suggest we re polished after brush paint, floor area in the 40-50 square, the master began to buy 4 group to help us paint brush 4 times, then we asked whether to brush primer, he said it can add a set of primer, now in the bag for him to do, he said without primer, direct brush 2-3 times finish it. I went to the TAOBAO to find a seller to sell the paint Tmall consulting, he also said the floor does not need primer... I'm confused. Does anyone know that the floor needs a primer? Floor brush a few times the general paint ah?

- Brush a few times to see the general requirements of paint, paint for the protection of its wear resistance, will brush a few times, good paint can brush, some foreign concept is to see not see wood paint, so the film should be as thin as possible, the paint requirements are very high.

- Q: Diamond, laminate flooring and laminate flooring to strengthen what kind of good

- The qualified laminate floor is covered with a layer or a plurality of special dipping thermosetting amino resin on the surface of the substrate, such as a high density board, etc., and the back is provided with a balance moisture proof layer, a front decorative layer and a wear-resistant layer.

- Q: just thinking outside the box and wondering if one could apply wax of some sort to the joints as it's installed? going to put this down in a kitchen

- its not a bad thing but be care-full you don't put too much in and prevent the joint fromm fully closing

- Q: The floors seem very dull although I have been told the finish should last 20 years. I have cleaned and once dry it is still dull. I have been told by a floor guy that I cannot buff it up because it is not real wood.

- The floor can be buffed and coated if it is an engineered wood floor. This guy obviously does not know how to do it. When recoating an engineered floors extra steps need to be taken to make sure the new finish will bond. Because most finishes will not bond well to aluminum oxide finish (what is usually on engineered floors). Talk to a few other wood flooring contractors in your area that are familiar with recoating engineered. 2 good systems for recoating engineered are using Bona prep followed by bona waterbased finish, or the tycote recoating system.

- Q: Also called oak oak, because I love the light colored floor, but do not want to choose solid wood, wood composite, so I want to ask you to feel any good?

- Yes, is to read "Li", is commonly known as oak, listen to the clerk said that this kind of wood is used to make wine storage wine is in the majority, said the flexibility is good, if the elasticity of the wood is good to what extent? Don't step on a pit? Hahaha

- Q: This has an engineered backing with real oak top about 1/4 thick.

- I've sanded dozens and dozens of them, but I've been a wood flooring contractor for a very long time. 1/4 inch of real oak is very comprarable to a solid oak floor. You can only sand 5/16 off of those before you reach the tongue/groove. Good Luck

Send your message to us

Herringbone Wooden Flooring 12mm European Oak E0

- Supplier:

BNBM Group Forest Products Co., Ltd.

BNBM Group Forest Products Co., Ltd.

- Loading Port:

- NINGBO

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches