Engineered Wood

Engineered Wood Related Searches

Fabricated Wood Engineered Wood Planks Engineered Real Wood Flooring Machined Wood Flooring Engineered Steel Buildings Engineered Stone Countertops Dark Wood Material Resin Furniture Used Greenhouse Finger Jointed Rubber Wood Indoor Insulation Synthetic Building Materials Commercial Plywood Hardened Stainless Steel Fake Wood Floors Colored Laminated Plywood Overlaid Plywood Environmentally Controlled Room German Woodworking Machines Simulated Hardwood Flooring Tarnished Stainless Steel Engineered Formwork System Engineered Timber Flooring Prices Home Insulation Prefabricated Housing Modules Environmental Maintenance Clean Environment Recycled Insulation Front Entry Wood Doors Broken Cast IronEngineered Wood Supplier & Manufacturer from China

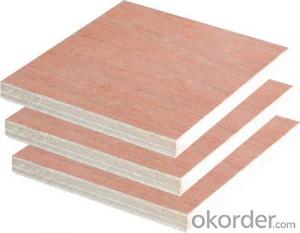

Engineered wood is a versatile product that combines the natural characteristics of wood with the benefits of modern technology. This innovative material is created by bonding together layers of wood veneers, strands, or particles, which are then subjected to high pressure and heat. The result is a strong, stable, and environmentally friendly alternative to traditional solid wood products. Engineered wood is widely used in various applications, including flooring, furniture, construction, and cabinetry. Its unique properties make it suitable for both residential and commercial settings, where it offers a durable and aesthetically pleasing solution.Engineered wood's exceptional strength and dimensional stability make it an ideal choice for a variety of usage scenarios. In flooring applications, for instance, engineered wood can withstand heavy foot traffic and resist warping, ensuring a long-lasting and attractive surface. In construction, it is used for structural components such as beams and joists, providing a reliable and efficient alternative to traditional timber. Additionally, engineered wood is a popular choice for furniture and cabinetry due to its ability to be easily shaped and finished, as well as its resistance to moisture and pests.

Okorder.com is a leading wholesale supplier of engineered wood products, offering a vast inventory to cater to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each engineered wood product meets the highest industry standards. Their extensive selection includes a range of species, finishes, and thicknesses, making it easy for customers to find the perfect engineered wood solution for their specific project requirements. By partnering with Okorder.com, customers can enjoy competitive pricing, fast shipping, and exceptional service, all while benefiting from the many advantages of engineered wood.

Hot Products