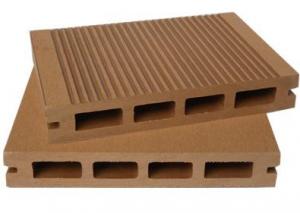

Outdoor Wood Plastic composite engineered Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Outdoor Wood Plastic composite engineered Decking

一.Product Description:

.

Outdoor Wood Plastic composite engineered Decking

Low flame spread / High slip resistance / No sting of wood / Contains no toxic chemicals or preservatives / Environmental friendly / Can be recycled with 100%

• High Strength

Outstanding screw and nail retention / High impact resistance / Great Compressive-tensile-shear strength / Modulus of elasticity: 20% greater than PVC

• Good appearance & nice touch

Natural feel & wood touch / Broad range of finishes and appearance, Multicolor, and needn't to painting

• Longevity

Its lifespan at least 10-15 years in the outdoor weather condition

• Install & Maintain easily

Easy to produce and easily fabricate / Easy to cut, fix and glue; Easy to tenon, drill and nail / Require less routine maintenance / No need staining & water Sealant

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

escriptions :

The characteristics of Wood generally had the problem of Waterproof and the serious concern to the environmental protection has been increasing day by day as well as it caused the Governments worldwide to stipulate the law to restrict to fell trees to reach the goal. To satisfy with the market's demand we utilized the characteristics of macromolecule to combine with the high technology of heavy pressure-micro foaming to produce an unique product with the invention and innovation of revolution. We call this new product " CELLwood®".

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

四. More picture for your reference

- Q: we want to use floor lights but i have small kids at home who could knock them off

- Most any floor light can be fixed to the floor. The cautions: Is the home a rental? Are you on a concrete slab or a wood floor? Does the slab have hot water heat tubing embedded? You will be putting screws into the floor. Would your land lord allow it? A hot water embedded concrete slab can leak if you accidentally puncture one of the tubes. If all of the above are ok, here we go.............. Do you have access to wood working tools? ie. table saw, electric hand drill etc. Or a neighbor/ friend with? The base plates of the floor lamps could be drilled directly through the metal and then screwed down, this easiest. Can you live with this cosmetic damage to the light base? If not, decorative wooden blocks can be fabricated out of hardwood. Stained, clear coated, and or painted. You will want to table saw a rabbit notch about 3/4 inch to 1 inch long on one end of each block at a blade depth that is a little less than the thickness of the light base. This will help clamp the light base firmly to the floor when screwed down. Make three blocks for each light base. The tops of the blocks can be decoratively tapered and the edges rounded over with a router to give a pleasing profile to the finished product. Hope this helps. you can e-mail me through Yahoo Answers with additional questions.

- Q: i was looking for a rabbit hutch and most seemed to have wire flooringwhy is that? and doesn't it hurt the rabbit's feet?should i get the ones with wire floors or solid wood floors?

- ditto what Cat said. Don't get a wire floored hutch - it'll really hurt your poor bunnies feet. It really isn't such a hardship to clean out a rabbit hutch - most rabbits will train themselves to toilet in one corner so put a little litter tray there and it'll help you out a bit. You sound like you'll be ok, you clearly thought a wire lined hutch was a bad idea or you wouldn't have asked :)

- Q: Prove that the floor(2x)=floor(x) floor(x 1/2)i need the proof with cases.

- Suppose that we split up x into its integer part y and its decimal part z (for example, we can split 3.6 up into 3 and 0.6). Then, we have: x = y z. Then: floor(2x) = floor(2y 2z), floor(x) = floor(y z), and floor(x 1/2) = floor(y z 1/2). For 0 < z < 1, floor(y z) = y for all integers y (y is defined to be an integer, so this is fine). As for floor(2y 2z) and floor(y z 1/2), we need to take cases. Now, if 0 < z < 0.5, then 0 < 2z < 1 and 0 < z 1/2 < 1 and so: 2y < 2y 2z < 2y 1 and y < y z 1/2 < y 1, which implies that 2x is some number between 2y and 2y 1 and that x 1/2 is some number between y and y 1, which implies: floor(2x) = x and floor(x 1/2) = x, so floor(2x) = floor(x) floor(x 1/2) when x is some integer plus a decimal between 0 and 0.5. As for the case 0.5 < z < 1, 1 < 2z < 2 and 1 < z 1/2 < 1.5, so: 2y 1 < 2y 2z < 2y 2 and y 1 < y z 1/2 < y 1.5, yielding floor(2y 2z) = 2y 1, floor(y z 1/2) = y 1, and floor(y z) = y, and so: floor(2y 2z) = floor(y z 1/2) floor(y z) == floor(2x) = floor(x) floor(x 1/2). Combining these two cases proves floor(2x) = floor(x) floor(x 1/2) when x is not an integer. To prove the case when x is an integer, notice that: floor(2x) = 2x, floor(x) = x, and floor(x 1/2) = x, when x is an integer, which shows that floor(2x) = floor(x) floor(x 1/2) when x is an integer. Combining these three cases yields floor(2x) = floor(x) floor(x 1/2) for all x (as required). I hope this helps!

- Q: my sister in law has asked me to remove the current tile flooring in her apartment and put a hardwood floor instead. some of the tiles are cracked or pulled back or have holes and i can see that the wood sub floor also has holes but still looks sturdy...in my opinion i believe i should remove the tiles along with the sub floor but my mother in law says to remove only the tile flooring and leave the wood sub floor as is. What do you all think? and btw this is my second time doing a flooring project, though its my first with this kind, any tips? &&the hardwood sub floor is nailed down if that means anything.

- without knowing what you mean by the wood sub floor also has holes it is hard to give good advice but if you feel it is still sturdy maybe you don't need to replace it. shouldn't make much of a difference regardless of what kind of hardwood floor you are putting down - nailed in place or floating

- Q: Hi I was just wondering if anyone knows of a good way to clean Laminate floors without smears. Thanks. x

- I can only tell you how I do mine, I use Mr. clean lemon scent and a micro fiber flat mop. I wash the whole floor and them rinse the mop head real well and then again go over the floor with clean warm water. That's it.

- Q: Do stages have sprung floors. I heard it is bad to dance on a floor that doesn't give any. So if the stage isn't sprung you could get injured. So do they have sprung floors? Thanks in advance!

- No they don't. But that is why we use our plié. So we don't get injured, but get the same spring.

- Q: Is not the length of the board is not the same, the interval is not the same?

- Generally used in the interval of 30CM

- Q: Just finished renovation, is preparing to clean the room, we use the laminate flooring, do not know need to be maintained, see the Internet with all kinds of essential oils, Buy it? More

- In fact, there is no need for maintenance, maintenance is to sell you to the United States and the United States. As long as the usual attention to clean up, do not use too much water, do not need maintenance, to really want to maintain can also once a year, your home is now just not necessary

- Q: Flooring paved, but the place where the wall is seated, how to solve the dust

- On the foot of the line it, or glue the glue on what specific plastic decoration workers on the line!

- Q: I am installing a bathroom but have been advised to only use wood, not tile or ceramic, flooring directly on top of the concrete because the tile will crack. What are my options?? The basement is poured if that makes a difference.

- If it's concrete, then it should be a grey color. Buy a brick colored paint. Pour paint into a tray. Use a large rectangular sponge and dip just the base of the sponge into the brick paint. Dab the sponge on newspaper to remove excess and then use the sponge to stamp rectangles on the floor in a pattern that would appear like bricks. When dry, paint floor with a non yellowing lacquer.

Send your message to us

Outdoor Wood Plastic composite engineered Decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords