Factory price wood plastic composite wpc decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Factory price wood plastic composite wpc decking

一.Product Description:

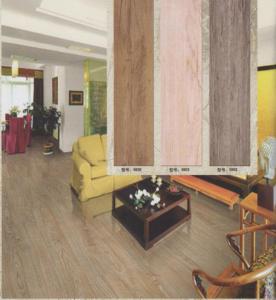

. With natural wood grain and looks like nature wood, less timber problems.

. Approx. 90% recycled materials, environmental friendly, saving forest resources.

. No paint, stain or oil required, low maintenance.

. Weather resistant, suitable from –40°C to 60 °C.

. Resistant to termite and insect attack, will not split, rot or warp.

. Easy to install and low labor cost.

. Cutting and drilling like timber.

. Span is 300~400mm.

. Six standard colors, standard length 2.2m or 3.6m, custom length available.

二.Technical Data

Slip resistance:

Boards of Techwoodn according to ASTM D2394-05. This is the best ranking for bare-foot slip resistance.

Weathering resistance:

Boards of Techwoodn have very low moisture uptake.This is key for mold and mildew resistance.

UV resistance:

4000 hours accelerated Xenon-arc Exposure,the Boards turned slightly more clear and colored.

Abrasion resistance:

The resistance to abrasion is similar to oak.

Fungus resistance:

Whatever fungus the wood composite is exposed to,it is extremely durable.

Moreover,aging test does not affect this durability.

三. FAQ

. What kinds of wpcproducts do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

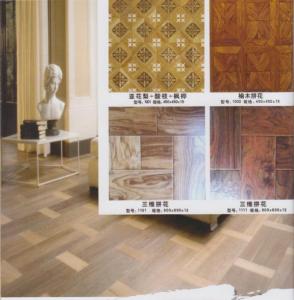

四. More picture for your reference

- Q: Three-tier parquet and multi-layer parquet What is the difference

- Three-story solid wood, relatively close to the solid wood flooring, foot feeling and the price difference is not much stability slightly improved, can be seen as pure solid wood flooring improved products; multi-layer solid wood is relatively pure wood composite floor, foot Pure solid wood slightly down, but in exchange for the high stability and low price, but also can do geothermal floor. So it has become Europe and the United States and other developed countries, ordinary residents of the first home pendant products! Is the absolute mainstream of the international market!

- Q: Is this a necessity? Will laminate flooring become damaged over time if an underlayment isn't used? The previous owner of this home installed a wood floor in the living room without an underlayment so if I want to use a flat transition between this floor and the floor I'm going to put in the next room I'll have to leave it out to keep the floors level. If I chose a cheap foam underlayment how thick will it be? Thanks.

- by laminate i assume you mean an interlocking pre- finished wood or wood composite flooring. underlayment ( vapor barrier) is nearly always used when applying the flooring over a concrete slab surface. not so much as when it is applied on an elevated floor ( raised foundation) The purpose of the underlayment (which is usually plastic or foam) is to keep moisture (from Below) from permeating the flooring causing warpage and damage over time. any good floor installer will use an underlayment regardless. if your problem is with underlayment thickness at the very least you should lay down heavy gauge plastic as your vapor barrier. the foam underlayment is also effective , but was primarily designed for a quieter walking surface. hope this helps

- Q: there is yellowing on my bathroom floor how can i get this up ? what do i buy it might be from the wetness/ rugs

- If you think about how you worded your question, it's kinda nasty. Yellowing on the bathroom floor? eeewwww

- Q: I am installing laminate floors for the first time and I had a question. We ripped out the carpet and their was wood along the trim with nails sticking up whice I assume was used to hold the carpet in place. I am pretty sure that I have to remove that before installing laminate, but I just wanted to make sure. Thank you

- Yes, you must remove any nails, staples etc. from the original flooring. Carefully remove any trim along the floor / wall and mark the back of it (so you will know where it goes back on), once the floor is installed. Good Luck. We put a floor down and it looks awesome. We used a bubble-type underlay that was recommended and have had absolutely no problems with it. Don't forget to look for the cleaning instructions:)

- Q: Floor material The choice of thickness As well as the installation of the precautions? Not very grateful! More

- In general, for all the wood flooring, are not suitable for heating, because the thermal expansion and contraction and heating effect, the wood floor of the water will be different from the environment, over time, causing damage to Cao Cao 丨 meter attack intestinal plate Warping, cracking, cracks

- Q: I am naming a line of laminate flooring that will be in stores. The name should suggest that the floor is quiet, peaceful and sounds like real hardwood. Any suggestions?

- For goodness sake whatever you do do not name the floor for its locking mechanism. No click this or that or blah blah lock. Customers don't care about that stuff and it makes the floor seem cheap and diy. Unless you're going for diy. Earthwood, Silentwood, Something Forest, or a name that refers to a particular geographic region, Appalachia, Rocky Mountain, etc., seem good to me. But what do I know, I just install the stuff.

- Q: Interior laying

- Loss = (real shop number * a tile area - real shop area) / real shop number * a tile area

- Q: Im getting a rabbit and making a c&c cage. what type of flooring should i use?

- You could use cloroplast (it's called Correx in the UK), however I prefer to use fleece blankets - they are easy to clean and easy to put in. I use a couple of blankets and stick them in the washing machine once a week, which works out pretty well. I put the hay in the rabbit's litterbox and they have a hay rack so it keeps things neat and tidy. Alternatively you could buy some vinyl lino tyles, which are pretty cheap and easy to stick down.

- Q: Hi, I have floor seats to a sold out concert, and my friends and I are in row 23, and I really want to be as close to the stage as possible. How does that work? Do they make you stay in your seats until the concert starts, then everyone runs up, or do people line up across the stage as soon as they get there?. I've never had floor seats, so I'm really excited =]

- usually floor 'seats' are just standing room. I've gotten floor tickets before and they have a row on them some times, idk why. If it's any kind of rock concert on the floor then it's standing room. You might want to check out the venue online and look at a seating chart though. It will not be you sit in seats then run up to the floor. It will also not be lining up in rows on the floor. If you have floor tickets, you stand wherever you can. My advise is to get there early so you can be closer to the stage.

- Q: Believe daddy still believe my mother?

- Is this a novel?

Send your message to us

Factory price wood plastic composite wpc decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches