Engineered Steel Buildings

Engineered Steel Buildings Related Searches

Engineered Wood Steel Building Homes Pre Engineered Steel Structure Post Steel Buildings Hardened Stainless Steel Stainless Steel Enclosures Galvanized Corrugated Steel Corrugated Galvanized Steel Surgical Stainless Steel Steel Arch Buildings Welded Stainless Steel Steel Homes Engineered Wood Planks Stainless Steel Fabrications Colored Stainless Steel Rusted Galvanized Steel High Speed Steel Engineered Stone Countertops Bleached Stainless Steel Painted Galvanized Steel Steel Modular Homes Tarnished Stainless Steel Stainless Steel Metals Steel Metal Homes Synthetic Building Materials Quilted Stainless Steel Weld Galvanized Steel Stainless Steel Doors Patinated Stainless Steel Stainless Steel FactoryEngineered Steel Buildings Supplier & Manufacturer from China

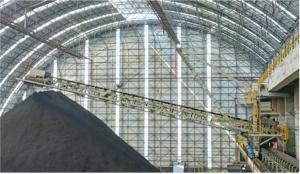

Engineered Steel Buildings are a type of prefabricated construction that utilizes steel as the primary material for its structural components. These buildings are designed to meet specific engineering standards and are known for their durability, strength, and flexibility in design. Engineered Steel Buildings are widely used in various industries, including commercial, industrial, and agricultural sectors. They are particularly popular for their ability to withstand harsh weather conditions, as well as their ease of installation and customization to suit specific needs. Okorder.com is a leading wholesale supplier of Engineered Steel Buildings, boasting a vast inventory that caters to the diverse requirements of clients from different sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Engineered Steel Building is manufactured to the highest standards and delivered promptly to meet project deadlines.Hot Products