High-end Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

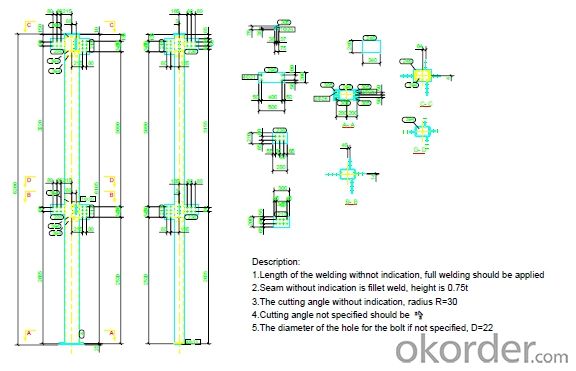

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

The new railway section of bullet train is the inspection and repair base for north China and

the inspection and repair center for the north section of Beijing to Shanghai high-speed

railway. The total area is 183,330 square meters. The steel structure adopt arch steel truss

with maximum span 36 meters.

- Q: What are the different types of steel coatings used in construction?

- There are several types of steel coatings used in construction, including galvanized steel coatings, epoxy coatings, polyurethane coatings, and powder coatings. Each type of coating offers unique benefits and is chosen based on factors such as corrosion resistance, durability, and aesthetic appeal.

- Q: What are the typical design considerations for steel food processing or manufacturing plants?

- Some typical design considerations for steel food processing or manufacturing plants include: 1. Hygiene and cleanliness: The design should prioritize easy cleaning and maintenance to ensure food safety and prevent contamination. 2. Adequate space and layout: Sufficient space should be allocated for processing, storage, and movement of materials, with an efficient layout to optimize workflow and minimize cross-contamination risks. 3. Temperature control: Proper insulation and ventilation systems should be incorporated to maintain desired temperatures for different processing areas. 4. Equipment and machinery requirements: The facility should be designed to accommodate the specific equipment and machinery needed for food processing, such as conveyors, mixers, ovens, and packaging machines. 5. Compliance with regulations: The design must adhere to local and international food safety standards and regulations, including those related to ventilation, waste disposal, and fire safety. 6. Sustainability and energy efficiency: Design considerations should include eco-friendly practices, such as utilizing energy-efficient lighting systems, incorporating renewable energy sources, and implementing water-saving measures. 7. Accessibility and safety: The facility should be designed to provide easy access for employees, including appropriate safety measures like emergency exits, proper lighting, and non-slip flooring. 8. Future expansion and flexibility: The design should allow for future growth and expansion, considering potential changes in production requirements or technological advancements in the food processing industry.

- Q: How to determine the thickness of anticorrosive paint for steel structure?

- Test method: check with dry film thickness tester. Each component detection 5, each value is the average of the 3 measuring points are 50mm coating dry film thickness.

- Q: What are the factors to consider when designing steel structures for healthcare facilities?

- When it comes to designing steel structures for healthcare facilities, there are several factors that need to be taken into account in order to ensure a safe and functional environment. Firstly, safety is of utmost importance in healthcare facilities, as it involves the well-being of patients, staff, and visitors. Therefore, it is crucial that steel structures are designed to withstand potential hazards such as earthquakes, extreme weather conditions, and fire. In order to achieve this, a proper structural analysis and design must be carried out to ensure that the building can withstand these forces. Secondly, flexibility is key in healthcare facilities, as they often undergo changes and expansions to accommodate evolving medical technologies and patient needs. With this in mind, steel structures should be designed to allow for future modifications and additions without compromising the overall integrity of the building. Infection control is another important factor to consider in healthcare facilities. To prevent the spread of diseases, steel structures should be designed in a way that minimizes the risk of contamination. This can be achieved by incorporating features such as smooth surfaces, easy-to-clean materials, and proper ventilation systems. Sustainability is also a key consideration, as healthcare facilities are typically large energy consumers. Therefore, it is important to incorporate sustainable design principles in the construction of steel structures. This can include maximizing energy efficiency by utilizing natural lighting, efficient HVAC systems, and renewable energy sources. Additionally, the use of recycled steel and other sustainable materials should be taken into consideration. Functionality is another crucial aspect to consider when designing steel structures for healthcare facilities. These facilities have unique requirements in terms of space planning, equipment installation, and specialized services. Therefore, the design should accommodate these functional needs by providing sufficient floor space, proper structural support for heavy medical equipment, and efficient circulation patterns for patients, staff, and supplies. Accessibility is also of great importance in healthcare facilities. They need to be accessible to all individuals, including those with disabilities or mobility limitations. Therefore, steel structures should be designed to comply with accessibility standards, providing features such as ramps, elevators, wide doorways, and accessible restrooms. Lastly, acoustics should not be overlooked. Noise can be a significant issue in healthcare facilities, affecting patient comfort and staff productivity. Therefore, steel structures should incorporate proper sound insulation measures, such as acoustic ceiling tiles, to minimize noise transmission between rooms and from external sources. By taking these factors into consideration during the design process, healthcare facilities can be constructed with the necessary safety, functionality, and sustainability to provide optimal care for patients and a conducive working environment for healthcare professionals.

- Q: How are steel structures designed for mezzanine floors?

- Steel structures for mezzanine floors are designed by considering various factors such as load-bearing capacity, layout requirements, and safety regulations. The design process involves analyzing the intended use of the mezzanine, determining the live and dead loads it will need to support, and selecting appropriate steel members and connections. Structural engineers calculate and design the steel framework to ensure it can safely withstand the expected loads and provide a stable and durable platform for the mezzanine floor.

- Q: Can steel structures be designed to be resistant to corrosion in marine environments?

- Steel structures can achieve a high level of resistance to corrosion in marine environments. Corrosion occurs naturally when steel is exposed to oxygen and moisture, resulting in rust formation. However, there are various effective strategies that can be utilized to enhance the corrosion resistance of steel structures in marine environments. One approach is the utilization of corrosion-resistant alloys, such as stainless steel or galvanized steel, which possess a greater resistance to the formation of rust. These alloys contain additional elements like chromium, nickel, or zinc that create a protective layer on the steel surface, preventing corrosive substances from reaching the underlying metal. Another method involves the application of protective coatings onto the steel structures. These coatings act as a barrier between the steel and the corrosive elements present in the marine environment. For example, epoxy coatings, polyurethane coatings, or marine-grade paints can be utilized to provide a protective layer that prevents water and oxygen from coming into contact with the steel. In addition to the use of corrosion-resistant alloys and protective coatings, proper design considerations also play a significant role in enhancing the corrosion resistance of steel structures in marine environments. For instance, designing structures with smooth surfaces and rounded edges can minimize the accumulation of corrosive substances and facilitate better water drainage. Adequate ventilation and drainage systems can also aid in the removal of moisture and prevent the buildup of corrosive agents. Regular inspection, maintenance, and repair are imperative in maintaining the corrosion resistance of steel structures in marine environments. Any signs of corrosion, such as rust spots or pitting, should be promptly addressed to prevent further damage. Implementing a comprehensive maintenance plan, which includes cleaning, surface preparation, and reapplication of protective coatings, can significantly prolong the lifespan of steel structures in marine environments. In conclusion, by utilizing corrosion-resistant alloys, protective coatings, proper design considerations, and regular maintenance, steel structures can be effectively designed to exhibit a high level of resistance to corrosion in marine environments.

- Q: What are the common misconceptions about steel structures?

- To clarify, there are various misconceptions surrounding steel structures. One of these is the belief that steel structures lack durability compared to concrete structures. However, this is far from the truth as steel structures have exceptional strength and resilience, enabling them to withstand harsh weather conditions, seismic activity, and even fire. Therefore, steel is an ideal material for construction purposes. Another misconception is that steel structures are more expensive than alternative construction materials. Although steel may have a higher initial cost, it is crucial to consider the long-term benefits. Steel structures require less maintenance and have a longer lifespan compared to other materials. Additionally, steel is recyclable, making it an environmentally friendly choice. There is also a misconception that steel structures are not visually pleasing. However, thanks to advancements in design and technology, steel structures can be tailored to suit any architectural style and can be aesthetically appealing. The versatility of steel allows for unique and innovative designs, which has made it a favorite among architects and designers. Lastly, it is often assumed that steel structures are noisy and prone to rust. While it is true that steel can generate noise when it expands and contracts due to temperature changes, proper insulation and soundproofing techniques can minimize this issue. Furthermore, steel structures can be coated with protective finishes to prevent rust and corrosion, ensuring their longevity. Overall, it is essential to debunk these misconceptions and acknowledge the numerous advantages of steel structures. They offer durability, cost-effectiveness, aesthetic appeal, and sustainability, making them a popular choice in the construction industry.

- Q: How are steel structures used in the construction of restaurants?

- Restaurants often utilize steel structures due to the many benefits they offer. Firstly, steel is renowned for its strength and durability, making it perfect for supporting the weight of large restaurant buildings. This allows for the creation of spacious dining areas, open floor plans, and even multi-story structures. Additionally, steel structures allow for design flexibility and can be tailored to meet the unique needs of each restaurant. This grants architects and designers the freedom to craft innovative and visually stunning restaurant spaces, such as open-air terraces, mezzanines, or expansive glass facades. Furthermore, steel structures are quick and efficient to construct. By manufacturing steel components off-site, construction time is significantly reduced. This is especially advantageous for time-sensitive restaurant projects or establishments eager to welcome customers as soon as possible. Moreover, steel structures possess excellent fire resistance, a crucial factor in restaurant construction where open flames and cooking equipment are present. Steel's ability to withstand fire ensures the safety of both the building and its occupants. Another important aspect is the environmental friendliness of steel structures. Steel is highly recyclable, reducing the consumption of natural resources in construction. Furthermore, energy-efficient designs incorporating insulation and other sustainable features can lead to lower energy costs for the restaurant. In conclusion, steel structures are indispensable in restaurant construction, providing strength, durability, design flexibility, quick construction, fire resistance, and environmental sustainability. These advantages make steel an ideal choice for creating functional, visually appealing, and safe dining spaces in restaurants.

- Q: What is the difference between structural steel and reinforcing steel?

- Construction projects rely on both structural steel and reinforcing steel, which have distinct roles and characteristics. Structural steel, also called mild steel or carbon steel, is primarily used in building construction and bridges. It is a durable material with high tensile strength, capable of withstanding heavy loads. Manufacturers create structural steel in various shapes like beams, columns, and plates, and it is often fabricated and welded to form complex structures. It provides the framework and support for the entire structure, ensuring stability and integrity. In contrast, reinforcing steel, also known as rebar, reinforces concrete structures. Its main purpose is to enhance the strength and durability of concrete, which is relatively weak in tension. By embedding reinforcing steel within concrete, the resulting composite material, known as reinforced concrete, becomes much stronger and able to withstand greater tensile forces. Rebar comes in different diameters and is usually placed in a grid-like pattern before pouring concrete. This creates a reinforced grid, preventing cracking or failure and providing additional strength. In summary, the difference between structural steel and reinforcing steel lies in their applications and functions. Structural steel serves as the primary load-bearing material, ensuring strength and stability. Reinforcing steel, on the other hand, strengthens and reinforces concrete structures, improving their ability to resist tension and other forces. Both materials are essential in construction, playing vital roles in ensuring the safety and longevity of various structures.

- Q: How are steel structures designed to provide adequate natural lighting?

- Steel structures are designed to provide adequate natural lighting through the strategic placement of windows, skylights, and transparent or translucent materials in the building envelope. These design elements maximize the entry of natural light into the space, reducing the need for artificial lighting during the day. Additionally, the use of reflective surfaces and light-colored finishes on the interior helps distribute and amplify the natural light, creating a brighter and more comfortable environment.

Send your message to us

High-end Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords