High-end Steel-work

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

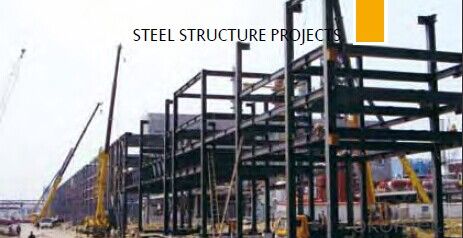

Steel Structure

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

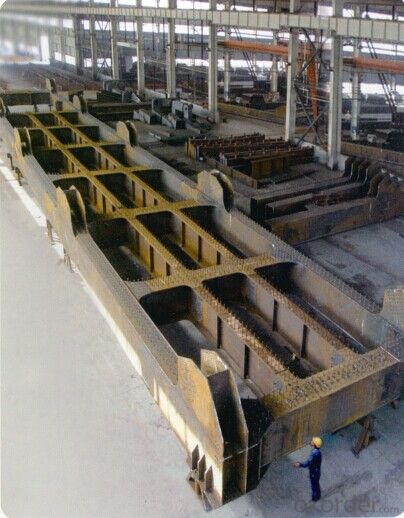

For the Steel structure project of Upper part of external

piperack for air separation and gasifying facilities of

460,000 tons MTO (Methanol to Olefins) project in

Duolun, we provide about 4,500 tons steel structure. It

is a heavy chemical indusry of national energy project.

- Q: What are the design considerations for steel data centers?

- Some key design considerations for steel data centers include structural integrity, thermal management, electrical distribution, fire protection, and scalability. Steel is a popular choice for data center construction due to its strength and durability. The structural design should ensure that the building can support heavy equipment and withstand potential natural disasters. Effective thermal management is crucial to prevent overheating of servers and other equipment, requiring proper insulation, ventilation, and cooling systems. Electrical distribution should be carefully planned to ensure sufficient power supply and backup options. Fire protection measures, such as fire-resistant materials and suppression systems, should be implemented to safeguard the facility and its valuable data. Lastly, scalability should be considered to accommodate future expansion and technological advancements.

- Q: What are the common design considerations for steel roof structures?

- There are several common design considerations that need to be taken into account when designing steel roof structures. These considerations include the following: 1. Load capacity: Steel roof structures must be designed to withstand various loads, such as dead loads (weight of the roof itself and any permanent fixtures), live loads (weight of people, equipment, and snow or wind loads), and environmental loads (such as seismic or wind forces). The structure must be able to safely support these loads without any risk of failure. 2. Span and spacing: The span and spacing of the steel roof structure will depend on the specific requirements of the building and the intended use of the roof. The design must take into consideration the desired clear span, which is the distance between supports, as well as the spacing of the structural members to ensure adequate support and stability. 3. Roof pitch: The pitch or slope of the roof is an important design consideration as it affects the overall aesthetic appeal, drainage performance, and structural integrity of the roof. The pitch must be carefully determined to prevent water from pooling on the roof and causing leaks or structural damage. 4. Roof covering: The type of roof covering, such as metal panels, shingles, or tiles, will impact the design of the steel roof structure. The design must accommodate the weight and installation requirements of the chosen roof covering. 5. Thermal expansion and contraction: Steel expands and contracts with temperature changes. The design must account for these thermal movements to prevent stress and potential failure. Techniques such as expansion joints or proper fastening systems can be incorporated to accommodate thermal expansion and contraction. 6. Fire resistance: Steel roof structures should be designed to meet fire resistance requirements. This may involve the use of fire-resistant materials or coatings and the inclusion of fire protection systems such as sprinklers. 7. Corrosion protection: Steel is susceptible to corrosion, especially in outdoor or humid environments. The design must incorporate appropriate corrosion protection measures, such as protective coatings or galvanization, to ensure the longevity and durability of the roof structure. 8. Accessibility and maintenance: The design should consider the accessibility of the roof for maintenance purposes, such as cleaning or repair. Safe and easy access points and walkways can be incorporated into the design to ensure the ongoing maintenance and inspection of the roof structure. By considering these design considerations, engineers and architects can develop steel roof structures that are safe, functional, and aesthetically pleasing while meeting the specific requirements of the building and its occupants.

- Q: How are steel structures designed to be resistant to impact from projectiles?

- Steel structures are designed to be resistant to impact from projectiles through several key design elements. Firstly, the use of high-strength steel with a high yield strength and toughness helps to absorb and distribute the impact energy. Additionally, the structural members are often designed with sufficient thickness and cross-sectional area to ensure adequate strength and stiffness. Moreover, certain structural configurations, such as incorporating sloping surfaces or deflecting elements, are employed to redirect or dissipate the projectile's energy. Finally, advanced computer simulations and testing techniques are employed to assess and optimize the structure's response to impact scenarios, ensuring it meets the required resistance criteria.

- Q: How are steel structures designed for resisting impact loads?

- Various methods and considerations are employed in the design of steel structures to withstand impact loads. One important factor is the careful selection of the appropriate material and design strength. Steel is renowned for its high strength-to-weight ratio, making it an optimal choice for structures that need to endure impact forces. Designers also take into account the specific requirements and potential sources of impact. This involves analyzing the magnitude, duration, and direction of the impact forces. For instance, structures located in earthquake-prone areas may require different design considerations compared to structures that are susceptible to vehicular impact. To enhance the impact resistance of steel structures, engineers may incorporate specific design features. These can include the utilization of reinforced sections, such as thicker beams or columns, or the addition of bracing elements to enhance overall structural stability. The design may entail a combination of dynamic analysis and computer simulations to accurately predict how the structure will behave under impact loads. Another consideration is the implementation of energy-absorbing mechanisms. These mechanisms aid in dissipating the impact energy and minimizing the potential damage to the structure. This can involve the use of dampers, shock absorbers, or other devices that absorb and dissipate the impact forces. Furthermore, steel structures can be designed with redundancy and reserve strength. This means that even if certain elements fail under impact, the structure can still maintain its overall integrity and resist collapse. This redundancy ensures that the structure can withstand unexpected impacts without experiencing catastrophic failure. Lastly, regular inspections and maintenance play a crucial role in ensuring the ongoing resistance of steel structures to impact loads. Periodic assessments can detect any structural weaknesses or damages that may have occurred over time. Timely repairs or reinforcements can then be implemented to uphold the structural integrity and enhance its ability to withstand future impact loads. In conclusion, the resistance of steel structures to impact loads is achieved through the selection of appropriate materials, consideration of specific impact requirements, incorporation of design features, use of energy-absorbing mechanisms, provision of redundancy and reserve strength, and regular inspections and maintenance. These measures guarantee that steel structures can effectively endure impact forces and maintain their structural integrity.

- Q: How do steel structures perform in terms of indoor environmental quality and occupant comfort?

- Steel structures can perform well in terms of indoor environmental quality and occupant comfort. Steel is a durable and reliable material that can provide good thermal performance, allowing for efficient heating and cooling. Additionally, steel structures can easily incorporate insulation, soundproofing, and ventilation systems, contributing to improved indoor air quality and comfort levels. With proper design and construction techniques, steel structures can create a comfortable and healthy environment for occupants.

- Q: How are steel structures used in renewable energy projects?

- Steel structures are widely used in renewable energy projects due to their strength, durability, and versatility. One of the primary applications of steel structures in renewable energy projects is in the construction of wind turbines. The tower, which supports the turbine, is typically made of steel due to its ability to withstand strong winds and vibrations. Steel also allows for tall and slender tower designs, maximizing the energy capture potential of wind turbines. In solar energy projects, steel structures are used in the construction of solar panel mounting systems. These structures provide a stable and secure platform for solar panels, ensuring optimal exposure to sunlight. Steel's high strength-to-weight ratio makes it an ideal material for these structures, as it allows for ease of installation and maintenance. Steel structures are also used in the construction of hydropower plants. In these projects, steel is used to build the penstocks, which are large pipes that transport water from the reservoir to the turbines. Steel's corrosion resistance and ability to withstand high pressure and temperature make it a suitable choice for penstock construction. Furthermore, steel structures are used in the construction of biomass and geothermal power plants. In biomass plants, steel is used to build the boilers and storage silos, which are necessary for biomass combustion. In geothermal power plants, steel is used to construct the well casings that extract hot water or steam from the earth's crust. Overall, steel structures play a crucial role in renewable energy projects, providing the necessary support, durability, and efficiency required for the successful generation of clean and sustainable energy.

- Q: How do steel structures handle vibration isolation and damping?

- Steel structures handle vibration isolation and damping through various methods. One common approach is to use specialized materials or devices, such as rubber isolators or dampers, which absorb or dissipate the energy generated by vibrations. These isolators or dampers are strategically placed within the structure to minimize the transmission of vibrations. Additionally, steel structures can be designed to have flexible connections or joints, which allow for some degree of movement and flexibility, thereby reducing the effects of vibrations. Overall, a combination of material selection, design techniques, and the incorporation of vibration control devices can effectively mitigate the impact of vibrations on steel structures.

- Q: How are steel structures designed to resist wind-induced vibrations?

- Steel structures are designed to resist wind-induced vibrations through a combination of structural engineering techniques. These include the use of stiffening elements like bracing or shear walls to increase the overall rigidity of the structure. Additionally, aerodynamic considerations such as the shape and profile of the building are taken into account to minimize wind loads. Damping devices, such as tuned mass dampers or viscous dampers, may also be incorporated to absorb and dissipate vibrations. Furthermore, computer simulations and wind tunnel testing are conducted to analyze the structural response to wind, ensuring the design can withstand the anticipated wind loads and vibrations.

- Q: What are the design considerations for steel structures in high winds?

- Some key design considerations for steel structures in high winds include: 1. Wind load analysis: Properly assessing the wind loads on the structure is crucial. This involves determining the wind speed, direction, and duration, as well as considering the topography and surroundings of the site. 2. Structural stability: Designing the structure to resist the external wind forces is essential. This involves ensuring adequate bracing and connections to withstand the wind loads and prevent structural failure or collapse. 3. Aerodynamic shapes: Incorporating aerodynamic shapes in the design helps to reduce wind resistance and minimize the impact of wind pressure on the structure. Smooth, curved surfaces and streamlined profiles can help to reduce drag and turbulence. 4. Material selection: Using high-strength steel with appropriate mechanical properties is important for withstanding the wind loads. The steel should have sufficient stiffness and resistance to deformation, allowing it to retain its shape and structural integrity under high wind pressures. 5. Connection design: The connections between steel members need to be carefully designed and detailed to ensure they can withstand the wind loads. Properly sized bolts, welds, or other fasteners should be used, and the connections should be designed to distribute the wind forces effectively. 6. Wind-induced vibrations: Wind can induce vibrations in steel structures, which can lead to discomfort or even damage. Proper damping mechanisms, such as tuned mass dampers or viscous dampers, may need to be incorporated to control these vibrations. 7. Maintenance and inspection: Regular inspection and maintenance are crucial to ensure the continued performance of steel structures in high winds. This includes checking for any signs of corrosion, loose connections, or damage that could compromise the structural integrity. Overall, designing steel structures in high winds requires a comprehensive understanding of the wind loads, structural stability, aerodynamics, material properties, and connection design to ensure the safety and performance of the structure.

- Q: Can steel structures be customized or modified easily?

- Yes, steel structures can be easily customized or modified. Steel is a versatile material that can be easily cut, welded, or shaped to meet specific design requirements. This flexibility allows for easy modifications in terms of size, shape, or functionality. Additionally, steel structures can be easily modified to accommodate changes in load requirements or to incorporate new features or additions. The ability to customize or modify steel structures easily makes them a popular choice in various industries, such as construction, manufacturing, and infrastructure development.

Send your message to us

High-end Steel-work

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords