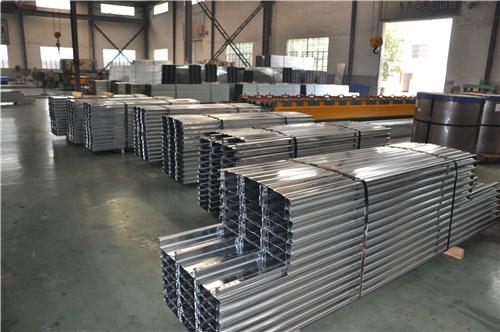

C Channel Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

In architecture, structural engineering or building, a purlin (or historically purline, purloyne, purling, perling) is any longitudinal, horizontal, structural member in a roof except a type of framing with what is called a crown plate. In traditional timber framing there are three basic types of purlin: purlin plate, principal purlin and common purlin.

Description

1)Price:FOB $500-650

2)Material:Q195-Q420,Q195,Q215,Q235,Q345

3)Certification:ISO9001, SGS, BV

4)Payment term:TT,L/C

Specofications

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

- Q: How is steel used in agricultural structures?

- Steel is used in agricultural structures for its strength and durability. It is commonly used to construct buildings such as barns, storage facilities, and animal shelters. Steel provides a reliable framework that can withstand heavy loads, harsh weather conditions, and the wear and tear associated with farming activities. Additionally, steel is often used in roofing and fencing materials, providing long-lasting protection for crops, livestock, and equipment.

- Q: How are steel structures designed for different floor systems?

- Steel structures are designed for different floor systems by considering factors such as the span, load requirements, and desired level of flexibility. The design process involves analyzing the structural needs and then determining the appropriate steel sections, connections, and support systems to ensure the integrity and functionality of the floor system. Additionally, considerations such as fire resistance, acoustics, and architectural constraints are also taken into account during the design process.

- Q: How are steel structures designed for blast impact loads?

- Steel structures intended to withstand blast impact loads go through a rigorous process to guarantee their resilience and ability to handle the immense forces produced by explosions. The design principles for these structures involve several crucial considerations. Engineers begin by analyzing potential blast scenarios, including the type of explosive, proximity, and direction of the blast. This analysis helps determine the magnitude and duration of the blast impact loads that the structure may encounter. The structural design takes into account how steel materials respond under blast loading. Steel is recognized for its high strength and ductility, enabling it to effectively absorb and distribute energy. The design incorporates the appropriate steel grades and structural elements to endure the sudden and intense forces generated by the blast. To ensure structural integrity, engineers employ advanced analytical techniques like finite element analysis (FEA) and computational fluid dynamics (CFD). These tools simulate the blast loading and its effects on the structure, allowing engineers to optimize the design and identify potential weak points. Another crucial aspect of blast-resistant design is the inclusion of redundancy and robustness. Redundancy ensures that multiple load paths are present in the structure, so that even if one element fails, the overall structure remains stable. Robustness involves designing the structure with additional strength and capacity to handle unexpected variations in blast loads. Special attention is also given to the connections between structural elements. Blast-resistant connections are designed to possess sufficient strength and flexibility to accommodate the dynamic nature of blast loads, enabling the structure to absorb and dissipate energy without catastrophic failure. Additionally, blast-resistant design may involve the utilization of sacrificial elements or blast-mitigating technologies. Sacrificial elements, such as sacrificial walls or barriers, are strategically placed to absorb blast energy and shield key structural components. Blast-mitigating technologies, such as blast-resistant coatings or blast-resistant windows, are employed to minimize the impact of the blast wave on the structure. Finally, the design process includes comprehensive testing and validation. Physical tests, such as blast testing on scaled models or full-scale structures, are conducted to verify the effectiveness of the design and ensure compliance with blast-resistant standards and regulations. In conclusion, the design of steel structures intended to withstand blast impact loads involves a meticulous process that considers blast scenarios, steel material properties, advanced analytical techniques, redundancy, connections, sacrificial elements, blast-mitigating technologies, and rigorous testing. This comprehensive approach ensures the creation of resilient structures capable of withstanding the extreme forces generated by explosions.

- Q: What are the design considerations for steel roof systems?

- When it comes to designing steel roof systems, there are several important factors to consider. These factors include structural integrity, durability, thermal performance, noise reduction, and aesthetics. One of the main things to consider when designing steel roof systems is ensuring that the structure is strong and stable. Steel is a durable material, but it's crucial to ensure that the roof is designed to withstand the various loads it will face, such as wind, snow, and seismic forces. The design should include proper support structures, connections, and bracing to ensure that the roof can handle these loads without failing. Durability is another essential aspect of steel roof system design. Steel is known for its longevity and resistance to weathering, but it's important to incorporate protective coatings or finishes into the design to prevent corrosion and extend the lifespan of the roof system. Regular maintenance and inspections are also necessary to identify and address any potential issues. Thermal performance is also an important consideration. The design should include insulation materials and techniques to minimize heat transfer between the inside and outside of the building. This can improve energy efficiency, reduce heating and cooling costs, and create a comfortable indoor environment. Noise reduction is often a concern with steel roofs because they can amplify sound. To address this, the design should incorporate insulation materials or barriers to minimize noise transmission. This is particularly important in commercial or residential buildings where noise control is crucial for occupants' comfort. Lastly, aesthetics play a significant role in steel roof system design. The design should take into account the desired architectural style and visual appeal of the building. Steel roofs offer a wide range of design options, including different colors, profiles, and finishes, allowing for customization that matches the overall design aesthetic of the building. In conclusion, the design considerations for steel roof systems include structural integrity, durability, thermal performance, noise reduction, and aesthetics. By carefully addressing these considerations, a well-designed steel roof system can provide a long-lasting, energy-efficient, and visually appealing solution for any building.

- Q: How are steel structures designed to provide adequate fire protection?

- The provision of adequate fire protection in steel structures is achieved through various measures. Firstly, fire-resistant coatings, such as intumescent paints or cementitious sprays, are often applied to the steel used in construction. These coatings expand when exposed to high temperatures, creating an insulating char layer that helps slow down heat transfer to the steel structure. In addition to fire-resistant coatings, fireproof insulation materials like mineral wool or vermiculite boards can also be incorporated into steel structures. These materials are placed between the steel members to enhance fire resistance and prevent the spread of fire. Furthermore, fire-resistant barriers and compartmentalization are commonly included in the design of steel structures. Fire-resistant barriers, such as firewalls or fire-resistant doors, are strategically positioned to divide the building into sections, thereby limiting the spread of fire and safeguarding occupants and property. Compartmentalization involves creating fire-resistant compartments within the structure, which can effectively impede the rapid spread of fire and provide safe evacuation routes. Moreover, the fire protection of a structure can be influenced by the selection and arrangement of steel members. Steel members with larger cross-sections or those embedded within concrete offer better fire resistance compared to thinner sections. The arrangement of steel members can also take into account fire-safety factors, such as avoiding long uninterrupted spans or providing additional fire protection to critical areas. Lastly, the inclusion of fire detection and suppression systems is crucial in steel structures to ensure early fire detection and effective fire suppression. These systems consist of smoke detectors, fire alarms, sprinkler systems, and fire extinguishers, strategically placed to minimize response time and contain the fire before it can cause extensive damage. In conclusion, steel structures are designed to provide adequate fire protection by employing fire-resistant coatings, insulation materials, barriers, compartmentalization, thoughtful member selection, and fire suppression systems. These measures collectively minimize the risk to occupants and property.

- Q: What are the considerations for steel structure design in earthquake-prone areas?

- When designing steel structures in earthquake-prone areas, several considerations need to be taken into account. Firstly, the structure should be designed to resist the seismic forces generated during an earthquake. This involves understanding the local seismicity and ground motion characteristics, and selecting appropriate design parameters such as the design earthquake magnitude and ground acceleration. Secondly, the structural system should be designed to ensure ductility and energy dissipation. This means incorporating features that allow the structure to deform and absorb seismic energy without collapsing, such as using moment-resisting frames or braced frames. The connections between structural elements should also be carefully designed to provide sufficient strength and ductility. Another consideration is the choice of materials and construction techniques. Steel, with its high strength and ductility, is often preferred for seismic-resistant structures. The construction process should also be carried out carefully, ensuring proper quality control and adherence to design specifications to maintain the structural integrity. Lastly, regular inspection and maintenance of the steel structure are crucial to ensure its long-term performance. This includes checking for any signs of damage or deterioration, repairing or strengthening as necessary, and conducting periodic seismic assessments to evaluate the structure's capacity to withstand future earthquakes.

- Q: How are steel structures used in the construction of museums and cultural centers?

- Due to their numerous advantages, steel structures are extensively utilized in the construction of museums and cultural centers. One of the primary rationales for the preference of steel is its strength and durability. Steel possesses the capability to withstand heavy loads and provide structural stability, rendering it suitable for large museum spaces that often necessitate unobstructed views and wide open areas without the need for columns or supports. As a result, architects are able to conceive distinctive and visually captivating designs. Furthermore, steel structures offer flexibility in terms of design and construction. They can be easily fabricated off-site and subsequently assembled on-site, thereby reducing construction time and minimizing disruptions to the surrounding area. This characteristic is especially beneficial for museums and cultural centers, which frequently operate within tight construction schedules and must remain accessible to the public throughout the building process. Moreover, steel structures provide cost-effectiveness. The material itself is relatively affordable, and its lightweight nature diminishes the requirement for heavy machinery during construction. Additionally, steel's extended lifespan and minimal maintenance demands make it an economically efficient choice in the long term. Regarding sustainability, steel is highly recyclable, making it an environmentally conscious option. It can be repurposed and reused, thereby reducing waste and minimizing the carbon footprint associated with the construction process. Furthermore, steel structures enable the integration of energy-efficient systems, such as solar panels and insulation, thereby contributing to the overall sustainability of the building. Lastly, steel structures offer a high level of safety and security. Steel boasts fire-resistant properties, providing protection against potential hazards. It is also resistant to pests, such as termites, which can pose a concern in certain regions. To summarize, steel structures play a vital role in the construction of museums and cultural centers by offering strength, durability, flexibility, cost-effectiveness, sustainability, and safety. Their ability to support expansive, unobstructed spaces, accommodate unique designs, and facilitate efficient construction processes makes steel the ideal choice for these architecturally significant and culturally important buildings.

- Q: How do steel structures support heavy loads and resist deflection?

- Steel structures support heavy loads and resist deflection primarily due to their high strength-to-weight ratio and inherent stiffness. The use of steel, which has excellent tensile strength and rigidity, allows for the construction of structures that can withstand significant loads without deforming or collapsing. Additionally, the design of steel structures often incorporates various supporting elements such as beams, columns, and trusses, which distribute the load evenly and efficiently throughout the structure, minimizing deflection.

- Q: How do steel structures compare to concrete structures in terms of cost and durability?

- Steel structures are generally more expensive to build than concrete structures due to the higher cost of steel materials and the need for specialized labor. However, steel structures offer superior durability and can withstand extreme weather conditions and heavy loads better than concrete structures, making them a more long-lasting investment in the long run.

- Q: What CL6-3a stands for the steel structure of the roof purlin

- The inner support component of the steel structure is made of high strength galvanized steel sheet, which is rolled into C and Z steel by precision machining.

Send your message to us

C Channel Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords