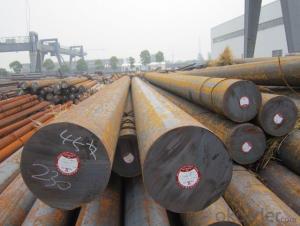

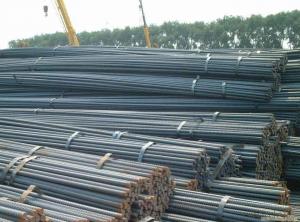

T12 Steel Bar

T12 Steel Bar Related Searches

Steel U Bar Stainless Steel Towel Bar 1 Inch Steel Bar Aluminum T Bar Stock Steel Deformed Bar T12 Led Tube Replacement Stainless Steel Bar Top 12 Gauge Stainless Steel Stainless Steel Square Bar T10 Rebar Stainless Steel Bar Stool 12 Cast Iron Continuous Cast Iron Bar Led Fluorescent Tube T12 Stainless Steel Soap Bar Led T12 Tube Light Bulbs Cast Iron T Stainless Steel Grab Bar Aluminum Stock Bar Bar Stool Stainless Steel Tmt Bars Stock Aluminum Bar 1 X 2 Aluminum Bar Stock Stainless Steel Barbell 1 2 X 1 2 Aluminum Bar Stock Forged Aluminum Bar Billet Steel Rebar 1 2 Aluminum Bar Stock 2 Aluminum Bar Stock Stainless Steel BarstoolT12 Steel Bar Supplier & Manufacturer from China

T12 Steel Bar, a type of carbon steel, is known for its excellent strength and durability. This product is widely recognized for its ability to withstand high levels of stress and is commonly used in various industries such as construction, automotive, and machinery manufacturing. Due to its superior properties, T12 Steel Bar is often employed in applications where high tensile strength and wear resistance are required.T12 Steel Bar is utilized in numerous scenarios, including the manufacturing of heavy-duty components and structural elements. Its versatility makes it a popular choice for a range of applications, from reinforcing concrete structures to producing durable mechanical parts. The product's ability to maintain its integrity under pressure and in harsh environments has made it a staple in the engineering and construction sectors.

Okorder.com is a leading wholesale supplier of T12 Steel Bar, boasting a substantial inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the T12 Steel Bar they provide meets the highest industry standards. This makes them a reliable source for businesses and individuals seeking to procure this robust and reliable material for their projects.

Hot Products