Steel Rail bar

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

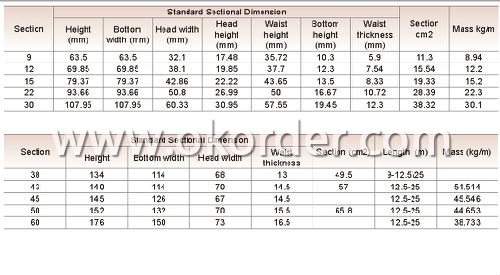

Specifications of Steel Rail Bar

Light Rail: 9kg, 12kg, 15kg, 22kg, 30kg

Heavy Rail: 38kg, 43kg, 45kg, 50kg, 60kg

Material Specifications:

Light Rail: GB 11264-89 Q235B, 55Q

Heavy Rail: GB 2585-81 50Mn, U71Mn

Length: 6M, 10M, 12M, 12.5M, 24M or as the requirements of the client

Applications of Steel Rail Bar

The Steel Rail Bar will be widely used to the railway, subway, transportation track, express, curve way, tunnel way and so on.

Package & Delivery of Steel Rail Bar

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Steel Rail Bar

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel rails be used in railway track monitoring systems?

- Yes, steel rails can be used in railway track monitoring systems. Steel rails are commonly used in railway tracks as they provide high strength and durability, making them suitable for heavy loads and frequent use. Railway track monitoring systems are designed to constantly monitor the condition of the tracks to ensure safe and efficient train operation. These systems use various sensors and technologies to detect and analyze track irregularities, such as cracks, wear, or misalignment. Steel rails can be easily integrated with these monitoring systems, allowing for accurate and real-time data collection. By utilizing steel rails in railway track monitoring systems, railway operators can effectively identify potential issues and proactively address any maintenance or repair needs, ensuring the safety and reliability of the railway network.

- Q: How are steel rails protected against damage caused by extreme weather conditions?

- Steel rails are protected against damage caused by extreme weather conditions through a variety of measures. One of the main methods is the use of weather-resistant coatings such as zinc or epoxy, which provide a protective barrier against corrosion. Additionally, regular inspections and maintenance help identify any potential issues and allow for timely repairs. Drainage systems are also installed to prevent water accumulation, which can lead to damage. Overall, a combination of coatings, maintenance, and drainage systems ensures that steel rails can withstand harsh weather conditions and remain durable.

- Q: What are the dimensions of standard steel rails?

- The dimensions of standard steel rails typically vary depending on the specific type and design, but they commonly measure around 6 inches in height and 30 feet in length.

- Q: Are steel rails susceptible to temperature changes?

- Temperature changes can impact steel rails, causing them to expand or contract. This phenomenon, known as thermal expansion and contraction, can have consequences for rail systems. When exposed to high temperatures, steel rails expand, which can lead to buckling or warping. If not dealt with promptly, this can result in track misalignment and even derailments. On the other hand, in cold temperatures, steel rails contract, leading to gaps between rail sections. This can affect track stability and increase the risk of accidents. To address these issues, rail systems employ various methods. Rail joints are designed with expansion gaps to accommodate thermal expansion, while rail fasteners and clips secure the rails tightly to the sleepers, allowing for some flexibility. Additionally, during extreme temperature conditions, rail maintenance and inspections are increased to identify and address any potential problems. By implementing these measures, the impact of temperature changes on steel rails can be minimized, ensuring the safe and efficient operation of rail systems.

- Q: Can steel rails be used in urban metro systems?

- Yes, steel rails can be used in urban metro systems. Steel rails are commonly used in metro systems around the world due to their durability, strength, and ability to withstand heavy loads and frequent use. They provide a smooth and stable track for trains, ensuring safe and efficient transportation within urban areas.

- Q: What are the different types of steel rail track monitoring systems?

- There are several types of steel rail track monitoring systems, including track geometry measurement systems, rail defect detection systems, wheel impact load detectors, and acoustic monitoring systems. These systems employ various technologies such as lasers, ultrasonic sensors, accelerometers, and acoustic sensors to monitor the condition of the rail track, detect defects, measure track geometry parameters, identify wheel impacts, and identify abnormal vibrations or noise. These monitoring systems help ensure the safety and efficiency of railway operations by providing real-time data for maintenance and inspection purposes.

- Q: How do steel rails affect noise pollution?

- Steel rails can contribute to noise pollution due to the vibrations caused by passing trains. The smooth surface of steel rails allows for efficient train travel but also creates a constant source of noise, especially at higher speeds. Additionally, the design and maintenance of the rail system, including the use of noise barriers and sound-dampening techniques, can help mitigate the impact of steel rails on noise pollution in surrounding areas.

- Q: What are the maintenance schedules for steel rails?

- The maintenance schedules for steel rails vary depending on several factors such as the usage intensity, environmental conditions, and the type of rail system. However, there are some general guidelines that can be followed for maintaining steel rails. Regular inspection is essential to identify any defects or issues that may affect the rail's performance. Inspections should be carried out at least once a month, but more frequent checks may be necessary for high-traffic rail lines. During these inspections, the rails should be examined for any signs of wear, cracks, or damage. Special attention should be given to areas where the rail is subject to heavy loads, such as curves or switches. Cleaning is another important maintenance task for steel rails. Accumulated dirt, debris, and rust can cause increased friction and wear, leading to potential safety hazards. Regular cleaning should be performed using appropriate equipment, such as rail vacuums or pressure washers, to remove any contaminants from the rail surface. For optimal performance, lubrication should be applied to the steel rails. This helps reduce friction between the wheels and the rails, minimizing wear and tear. Lubricants specifically designed for rail systems should be used, and the frequency of lubrication will depend on the rail usage and environmental conditions. In some cases, lubrication may be required weekly, while in others, monthly or quarterly application may suffice. In addition to regular inspections, cleaning, and lubrication, periodic maintenance tasks like rail grinding and replacement of worn-out components may also be necessary. Rail grinding helps maintain a smooth and level rail surface, reducing the risk of wheel damage and enhancing ride quality. Replacement of worn-out components, such as rail pads or fasteners, should be carried out as needed to ensure the structural integrity of the rail system. It is important to note that the specific maintenance schedules for steel rails should be developed based on the manufacturer's recommendations, industry standards, and the rail operator's experience. Regular monitoring and assessment of the rail system's condition will help determine the appropriate frequency and scope of maintenance tasks to ensure safe and efficient rail operations.

- Q: How do steel rails contribute to train wheel wear reduction?

- Steel rails contribute to train wheel wear reduction in several ways: 1. Hardness: Steel rails are made from high-quality steel that is hardened to withstand the immense pressure and friction caused by train wheels rolling over them. The hardness of the rails provides a durable surface that resists wear and tear, thereby reducing the wear on train wheels. 2. Smooth surface: Steel rails are carefully manufactured to have a smooth and even surface. This smoothness helps to reduce the friction between the train wheels and the rails, resulting in less wear on the wheels. A rough or uneven rail surface can cause excessive wear on the wheels, leading to increased maintenance and replacement costs. 3. Resistance to deformation: Steel rails have excellent resistance to deformation, meaning they can withstand the weight and force of passing trains without bending or warping. This resistance to deformation ensures that the rails maintain their shape and alignment, preventing excessive contact and wear on the train wheels. 4. Regular maintenance: Steel rails require regular maintenance to ensure their optimal performance. This maintenance includes regular inspections, cleaning, and lubrication. By keeping the rails in good condition, the risk of wheel wear is minimized. Maintenance crews also monitor and correct any issues such as rail defects or misalignments, which can contribute to excessive wheel wear if left unaddressed. 5. Proper track design: Steel rails are laid on a well-designed track system, which includes features like proper alignment, appropriate curves, and optimized track geometry. These design aspects help distribute the weight of the train evenly, reducing the concentration of forces on any particular section of the wheel. Consequently, this reduces the wear and tear on the wheels and extends their lifespan. In conclusion, steel rails contribute to train wheel wear reduction through their hardness, smooth surface, resistance to deformation, regular maintenance, and proper track design. By providing a durable and low-friction surface for the train wheels to roll on, steel rails help to minimize wear and tear, thereby improving the efficiency and safety of train operations.

- Q: How are steel rails protected from extreme weather conditions?

- Steel rails are protected from extreme weather conditions through various measures such as galvanization, paint coatings, and regular maintenance. Galvanization involves applying a layer of zinc to the steel rails, which forms a protective barrier against corrosion caused by moisture or exposure to harsh weather elements. Additionally, paint coatings are applied to further shield the rails from moisture, ultraviolet rays, and other damaging factors. Regular maintenance, including inspections and repairs, helps identify and address any potential weather-related issues promptly, ensuring the long-term durability and safety of the steel rails.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Steel Rail bar

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords