Steel Light Rail Q235B with Multiple Specifications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

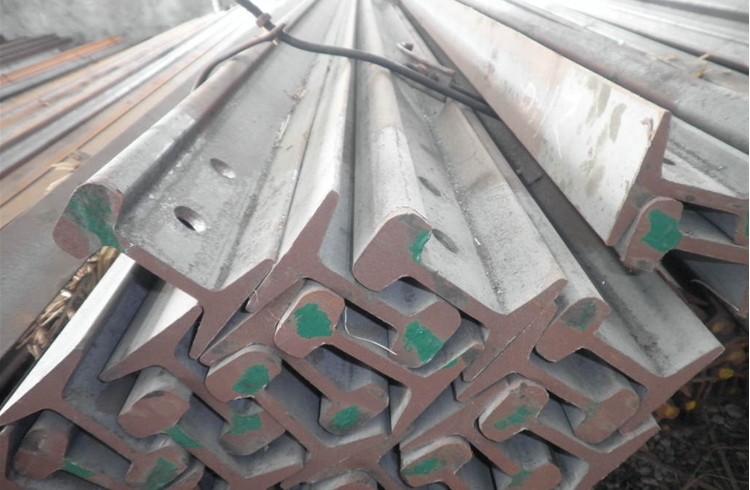

Specifications of Steel Light Rail Q235B with Multiple Specifications:

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usages of Steel Light Rail Q235B with Multiple Specifications:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Steel Light Rail Q235B with Multiple Specifications:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What is the process of grinding steel rails?

- The process of grinding steel rails involves several steps to ensure the smoothness, accuracy, and safety of the rail tracks. Firstly, the rail surface is inspected for any defects or irregularities, such as cracks, wear, or corrugations. This is done using specialized equipment, such as ultrasonic testing, to detect any flaws that may affect the integrity of the rail. Once the inspection is complete, the next step is to remove any imperfections from the rail surface. This is typically done using a grinding machine, which consists of large rotating grinding stones or wheels. These grinding stones are mounted on a grinding carriage, which is then moved along the length of the rail. During the grinding process, the grinding stones rotate and apply pressure to the rail surface, removing the defects and smoothing out any irregularities. The grinding machine is operated by skilled technicians who carefully control the speed, pressure, and depth of the grinding to ensure precise and consistent results. After the initial grinding, the rail surface is checked again to ensure that all defects have been removed and the surface is smooth and even. Any remaining imperfections are addressed by making additional passes with the grinding machine until the desired standard is achieved. Finally, the rail surface is inspected once more to verify that it meets the required specifications. This includes checking for proper alignment, smoothness, and gauge accuracy. The grinding process is considered complete when the rail surface meets the necessary standards for safety and operational efficiency. Overall, the process of grinding steel rails is crucial for maintaining the integrity and performance of rail tracks. It helps to remove defects, improve surface quality, and ensure the smooth and safe operation of trains.

- Q: What are the safety measures for working on electrified steel rail tracks?

- To ensure the well-being of workers, it is of utmost importance to adhere to safety measures when working on electrified steel rail tracks. Consider the following essential safety measures: 1. Ensure Proper Training: Workers should receive adequate training on handling electrified rail tracks, including understanding the associated electrical hazards, emergency protocols, and safe tool and equipment handling. 2. Use Personal Protective Equipment (PPE): Workers must consistently wear appropriate PPE, such as insulated gloves, safety glasses, hard hats, and flame-resistant clothing. Additionally, the use of insulated tools is crucial to minimize the risk of electrical shock. 3. Implement Lockout/Tagout (LOTO) Procedures: Prior to commencing work, the electrical power supply to the tracks must be effectively locked out or tagged out to prevent accidental energization. Access to LOTO devices should be restricted to authorized personnel only. 4. Conduct Thorough Risk Assessments: Before initiating work on electrified rail tracks, perform a comprehensive risk assessment to identify potential hazards, such as live wires, faulty electrical equipment, or overhead lines. Implement appropriate control measures to mitigate these risks. 5. Maintain Clear Communication: Maintain open and clear communication with fellow workers, signaling personnel, and train operators. Ensure that all parties are well-informed about the ongoing work and any potential hazards that may arise. 6. Establish Safe Work Zones: Clearly define boundaries and establish safe work zones to prevent unauthorized access to the electrified tracks. Utilize barriers, signage, and warning lights to clearly indicate the presence of electrical hazards. 7. Utilize Proper Tools and Equipment: Only use tools and equipment specifically designed for working on electrified rail tracks. Regularly inspect and maintain insulated tools and equipment to ensure their integrity. 8. Proper Ladder Usage: When working at heights near electrified tracks, utilize ladders made of non-conductive materials and position them away from live wires or overhead lines. Workers should refrain from leaning or touching any electrical components while on the ladder. 9. Be Prepared for Emergencies: Establish a well-defined emergency response plan in the event of accidents or incidents. Train workers on emergency procedures, including evacuation routes, first aid, and how to respond to electrical shock or burns. 10. Conduct Regular Inspections and Maintenance: Regularly inspect the electrified rail tracks, electrical equipment, and tools to identify potential issues or defects. Any faulty equipment or infrastructure should be promptly reported and repaired to prevent accidents. By prioritizing safety and adhering to these safety measures, workers can effectively minimize the risks associated with electrical hazards and maintain a safe working environment on electrified steel rail tracks.

- Q: How are steel rails affected by heavy loads?

- Steel rails are affected by heavy loads primarily through wear and deformation. The repeated pressure and friction from heavy loads can cause the rails to gradually wear down, leading to a decrease in their overall lifespan. Additionally, heavy loads can cause the rails to deform or bend slightly, which can affect their alignment and stability. Regular maintenance and inspection are essential to ensure the safety and longevity of steel rails under heavy loads.

- Q: How do steel rails contribute to train ride quality?

- Train ride quality is enhanced by steel rails in several ways. Firstly, the smooth and stable surface they provide allows the train to run smoothly. The design and manufacturing of steel rails guarantee their straightness and absence of deformities or irregularities. Consequently, the train wheels consistently make contact with the rails, resulting in reduced vibrations and a smoother ride. Moreover, steel rails possess remarkable strength and durability. They can withstand the heavy loads and constant impact of the train, maintaining their shape and integrity over time. This stability and strength contribute to a more comfortable and secure journey for passengers. In addition, steel rails play a vital role in maintaining the alignment and stability of the train. They are firmly fastened to the sleepers or ties, which are in turn fixed to the ground. This ensures that the tracks remain in place without shifting or moving during the train's motion. The stability of the tracks is crucial for a smooth and safe ride, as any misalignment or movement could cause discomfort for passengers. Furthermore, steel rails are specifically designed to reduce noise during train operations. The smooth surface and precise alignment of the rails minimize friction and noise generated as the train wheels roll over them. This contributes to a quieter and more enjoyable journey for passengers. In conclusion, steel rails are an indispensable element in enhancing train ride quality. They provide a smooth and stable surface, ensure alignment and stability, and reduce noise. As a result, passengers can experience a comfortable, secure, and enjoyable journey during train travel.

- Q: Can steel rails be used in railway systems with multiple tracks?

- Indeed, railway systems with multiple tracks can incorporate the utilization of steel rails. Globally, steel rails are widely employed in railway systems owing to their exceptional endurance, robustness, and capacity to bear hefty burdens. In the context of railway systems with numerous tracks, steel rails are positioned in parallel as a means to establish a steadfast and dependable groundwork for train traversal. The spacing between these tracks is typically configured to facilitate the accommodation of multiple tracks, thereby enabling the concurrent operation of several trains. The design of steel rails is specifically engineered to endure the weight and impact exerted by trains, thus ensuring secure and efficient transportation across the expanse of multiple tracks within railway systems.

- Q: Seamless rail is not afraid of expansion and contraction?

- The rail welding seamless rail is 25 meters long up into several hundred meters or even thousands of meters long, and then put on the roadbed, seamless rail gap of 11 mm between each segment. Seamless rail is seamed, will also be affected.

- Q: How do steel rails contribute to reducing train maintenance downtime?

- Steel rails contribute to reducing train maintenance downtime in several ways. Firstly, steel rails have high durability and can withstand heavy loads and frequent train traffic without significant wear and tear. This reduces the need for frequent repairs or replacements, resulting in less downtime for maintenance. Secondly, steel rails have excellent resistance to corrosion, which is particularly crucial for outdoor railway tracks exposed to various weather conditions. By preventing rust and deterioration, steel rails require less maintenance and downtime for necessary repairs. Additionally, steel rails offer superior stability and alignment, minimizing the occurrence of track irregularities and ensuring smoother train operations. This reduces the likelihood of derailments or accidents, thereby reducing maintenance downtime caused by emergencies or accidents. Overall, the robustness, corrosion resistance, and stability of steel rails play a vital role in minimizing train maintenance downtime and ensuring efficient and reliable railway operations.

- Q: How do rail profiles affect the performance of steel rails?

- Rail profiles have a significant impact on the performance of steel rails. The shape and dimensions of rail profiles determine the load-bearing capacity, stability, and wear characteristics of the tracks. Different rail profiles are designed to optimize specific performance factors such as track stability, reducing noise and vibration, and enhancing the overall durability and lifespan of the rails. Therefore, selecting the appropriate rail profile is crucial for ensuring efficient and safe railway operations.

- Q: Can steel rails be used in railway track monitoring systems?

- Railway track monitoring systems can utilize steel rails, which are commonly used in railway tracks due to their high strength and durability. Steel rails are suitable for heavy loads and frequent use, making them an ideal choice. These monitoring systems constantly assess the condition of the tracks to ensure safe and efficient train operation. They employ various sensors and technologies to detect and analyze track irregularities, including cracks, wear, or misalignment. By integrating steel rails into these systems, accurate and real-time data collection becomes possible. This integration enables railway operators to effectively identify potential issues and proactively address any maintenance or repair needs, thereby ensuring the safety and reliability of the railway network.

- Q: What are the specifications for steel rails used in high-speed rail networks?

- The specifications for steel rails used in high-speed rail networks typically include stringent requirements for material composition, strength, and durability. These rails are typically made of high-quality steel alloys that are designed to withstand high levels of stress, fatigue, and wear. They are often required to meet specific dimensional tolerances and have a smooth surface finish to ensure efficient and safe operation at high speeds. Additionally, the rails must adhere to strict standards for straightness, alignment, and flatness to ensure smooth and stable train movements.

Send your message to us

Steel Light Rail Q235B with Multiple Specifications

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords