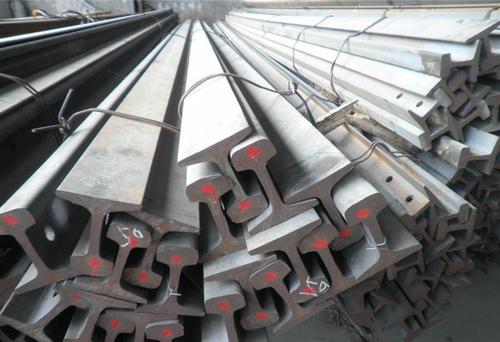

Steel Light Rail with High Quality for Warehouse ,Minas, Structures

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Steel Light Rail with High Quality for Warehouse ,Minas, Structures:

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Usages of Steel Light Rail with High Quality for Warehouse ,Minas, Structures:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Packaging & Delivery of Steel Light Rail with High Quality for Warehouse ,Minas, Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Light Rail with High Quality for Warehouse ,Minas, Structures:

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Why buy Materials & Equipment from OKorder.com?

A3: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Images:

- Q: Can steel rails be used for airport tram systems?

- Yes, steel rails can be used for airport tram systems. Steel rails are commonly used in tram systems due to their durability, strength, and ability to handle heavy loads. Additionally, steel rails provide a smooth and stable ride, making them suitable for airport tram systems that require efficient transportation of passengers and luggage.

- Q: How do steel rails affect the comfort of passengers?

- Steel rails have a significant impact on the comfort of passengers as they provide a smooth and stable ride. The use of steel rails ensures minimal vibrations and reduces the noise level, resulting in a more comfortable journey for passengers.

- Q: Can steel rails be used in subway systems?

- Yes, steel rails can be used in subway systems. Steel rails are commonly used in subway systems worldwide due to their durability, strength, and resistance to wear and tear. They provide a smooth and stable track for subway trains, ensuring safe and efficient transportation within the subway network.

- Q: The hardness of the crane wheel is larger than that of the rail

- You have to look at the actual wear and tear situation, because there are many tracks on the market are Q235, and the ordinary steel plate is a model, and there is 55Q's better, but the price is also expensive,

- Q: What are the common challenges in maintaining steel rails?

- Some common challenges in maintaining steel rails include wear and tear due to heavy train traffic, corrosion from exposure to moisture and chemicals, and the need for regular inspections and repairs to ensure safe and efficient train operations. Additionally, changes in temperature and stress can cause rail buckling or warping, requiring continuous monitoring and maintenance.

- Q: Can steel rails be used in railway systems with multiple tracks?

- Indeed, railway systems with multiple tracks can incorporate the utilization of steel rails. Globally, steel rails are widely employed in railway systems owing to their exceptional endurance, robustness, and capacity to bear hefty burdens. In the context of railway systems with numerous tracks, steel rails are positioned in parallel as a means to establish a steadfast and dependable groundwork for train traversal. The spacing between these tracks is typically configured to facilitate the accommodation of multiple tracks, thereby enabling the concurrent operation of several trains. The design of steel rails is specifically engineered to endure the weight and impact exerted by trains, thus ensuring secure and efficient transportation across the expanse of multiple tracks within railway systems.

- Q: How do steel rails handle different weather conditions?

- Steel rails are designed to handle different weather conditions effectively. The properties of steel make it highly resistant to various weather elements. In cold weather, steel rails are able to withstand freezing temperatures without becoming brittle or developing cracks. This is due to the low thermal expansion coefficient of steel, which allows it to contract and expand without causing damage. Additionally, steel rails have a high tensile strength, enabling them to bear heavy loads even in extreme cold. In hot weather, steel rails are also well-suited to cope with high temperatures. Steel has a relatively high melting point, so it does not soften or lose its structural integrity under normal operating conditions. Moreover, steel rails have excellent heat dissipation properties, allowing them to cool down quickly and maintain their strength. Steel rails are also resistant to corrosion, making them suitable for use in various weather conditions, including wet and humid environments. The rails are often coated with protective layers, such as zinc or paint, to further enhance their resistance to corrosion. This protective coating prevents moisture from reaching the steel surface, thus preventing rusting and prolonging the lifespan of the rails. Furthermore, steel rails have good traction properties, which are essential for safe train operations in different weather conditions. The design of the rail profile, along with the use of friction modifiers or anti-skid materials, ensures that trains maintain sufficient grip on the tracks, even during rainy or snowy weather. In summary, steel rails are engineered to withstand different weather conditions. They can endure extreme cold, high temperatures, moisture, and provide reliable traction for train operations. The durability, strength, and corrosion resistance of steel make it the preferred material for rail infrastructure, ensuring safe and efficient transportation in all weather conditions.

- Q: What are the safety precautions taken during steel rail welding?

- During steel rail welding, several safety precautions are taken to ensure the safety of the workers and the quality of the weld. These precautions include wearing appropriate personal protective equipment such as welding helmets, gloves, and protective clothing. Adequate ventilation is provided to minimize exposure to welding fumes and gases. Workers are trained to handle welding equipment properly and follow proper welding procedures. Fire extinguishers and fire blankets are readily available to control any potential fires. Regular inspections are conducted to ensure that the welding equipment is in proper working condition. Overall, these safety precautions are crucial to prevent accidents, protect workers from hazards, and maintain the integrity of the steel rail welding process.

- Q: What is the average weight of steel rails?

- The average weight of steel rails can vary depending on the specific type and size, but typically ranges from 85 to 175 pounds per yard.

- Q: What are the different types of rail welds used with steel rails?

- Steel rails commonly utilize several different types of rail welds. These include: 1. The most commonly used weld in rail construction is the Flash Butt Weld. This method involves using electric current to heat the rail ends and then pressing them together to create a seamless joint. It results in a strong and reliable bond between the rails. 2. Another type of weld is the Aluminothermic Weld, also known as a thermit weld. This method utilizes a chemical reaction to generate the necessary heat for joining the rail ends. By igniting a mixture of aluminum powder and iron oxide, a high-temperature reaction occurs, melting the steel and forming a molten pool. The rail ends are then brought together, and the molten metal solidifies to create a solid joint. 3. In situations where flash butt welding or aluminothermic welding is not feasible, Gas Pressure Welding is employed. This method involves heating the rail ends using a gas flame and applying pressure to forge the ends together. Skilled operators and specialized equipment are required to achieve a strong and reliable joint. 4. Electric Arc Welding utilizes an electric arc to heat the rail ends and applies pressure to forge them together. This method is typically used for repairs and maintenance work as it is less time-consuming and requires less specialized equipment compared to other welding methods. 5. Stud Welding is employed to attach various accessories, such as guardrails, signals, or fixtures, to the rail. This type of welding involves shooting a stud or threaded bolt onto the rail surface using an electric arc. The stud securely attaches, providing a strong connection for the accessory. Each type of rail weld has its own set of advantages and disadvantages. The choice of which method to use depends on factors such as the specific application, location, and available resources. Proper welding techniques and quality control are crucial to ensure the integrity and durability of rail welds.

Send your message to us

Steel Light Rail with High Quality for Warehouse ,Minas, Structures

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords