High Quality HR Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

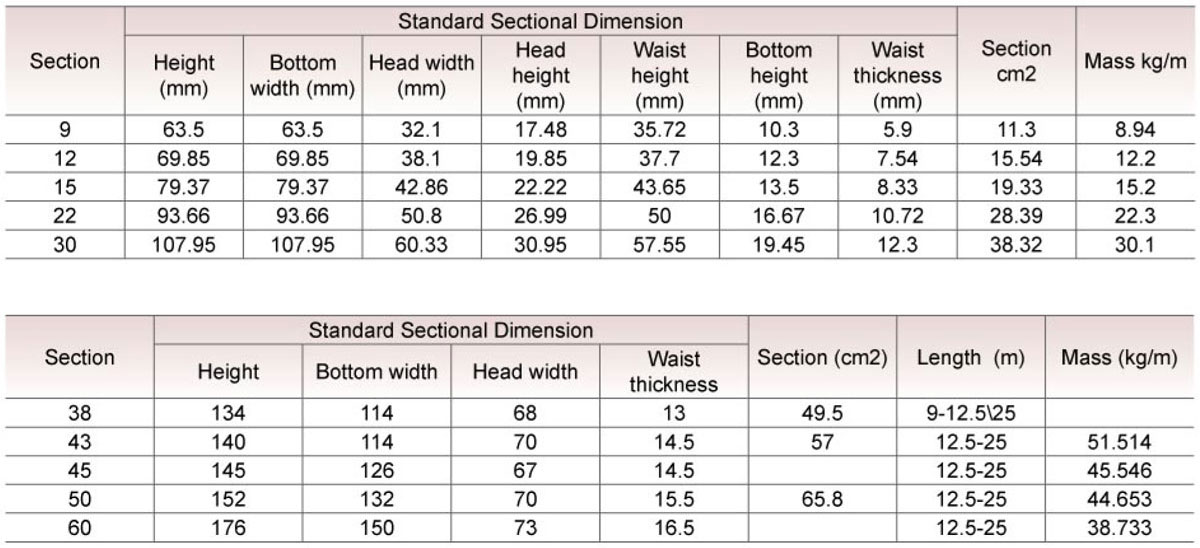

Specifications of High Quality HR Steel Rail:

Available Standard:

Light rail: GB11264-89

Heavy rail: GB2585-81

Available Material Grade:

Light rail:Q235B, 55Q

Heavy rail: 50MN, U71MN

Apllications of Steel Rail

railway

subway

transportation track

express

curve way

tunnel way

Package and Delivery of High Quality HR Steel Rail

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of High Quality HR Steel Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Are steel rails susceptible to damage from heavy rainfall or flooding?

- Heavy rainfall or flooding typically does not cause damage to steel rails. Steel is a robust and durable material that resists water damage. Nevertheless, prolonged exposure to water can eventually result in rust formation, which may weaken the rails and compromise their structural integrity. Consequently, it is of utmost importance to conduct regular maintenance and inspections on steel rails to guarantee their safety and prevent any potential harm. Furthermore, in regions prone to heavy rainfall or flooding, it is advisable to implement adequate drainage systems and take precautionary measures to minimize any potential risks to the steel rails.

- Q: How are steel rails maintained in curved railway tracks?

- Steel rails in curved railway tracks are maintained through regular inspections, monitoring, and maintenance practices. This includes checking for any signs of wear, damage, or defects on the rails, such as cracks or excessive wear on the inside of the curve. If any issues are detected, appropriate actions are taken, such as grinding or replacing the affected rail sections. Additionally, measures like lubrication, adjusting the rail alignment, and monitoring the track's stability are undertaken to ensure safe and efficient operations on curved railway tracks.

- Q: How are steel rails protected from theft and vandalism?

- Steel rails are protected from theft and vandalism through various measures that aim to deter potential perpetrators and ensure the security of these essential infrastructures. One of the primary methods employed is the use of security systems and surveillance technology. Many railway companies install closed-circuit television (CCTV) cameras along the tracks to monitor any suspicious activities. These cameras are often equipped with motion sensors and can transmit live feeds to security personnel who can respond swiftly in case of a breach. In addition to surveillance, railway companies also employ physical barriers and fencing to restrict unauthorized access to the rail tracks. Perimeter fences, barriers, and gates are often installed to deter thieves and vandals from approaching the rails. These physical deterrents are designed to make it more challenging for individuals to remove or tamper with the steel rails. Furthermore, some railway companies have implemented advanced security measures such as the use of GPS tracking systems and sensors embedded within the rails themselves. These systems can detect any unauthorized tampering or movement of the rails, immediately alerting authorities to the potential theft or vandalism. Collaboration with law enforcement agencies is another crucial aspect of protecting steel rails. Railway companies often work closely with local police departments and railway security forces to ensure regular patrols and timely response to any security threats. This collaboration helps in deterring potential criminals and ensures a swift response when incidents occur. Lastly, public awareness campaigns are often conducted to educate the public about the importance of rail security and the consequences of theft or vandalism. This helps in creating a sense of collective responsibility and encourages individuals to report any suspicious activities they may witness near the tracks. Overall, the protection of steel rails from theft and vandalism is a multi-faceted approach that combines surveillance technology, physical barriers, advanced security systems, collaboration with law enforcement, and public awareness. These measures collectively work to deter potential criminals and ensure the safety and integrity of rail infrastructure.

- Q: What is the connection mode of the return cable on the rail?

- Current transformer installation should pay attention to several points: one is the two circuit transformer is not allowed to open, to prevent the generation of high voltage induction harm, two is the two circuit grounding point, three is the current level of transformer should be greater than or equal to the maximum current in the main circuit, otherwise will exceed the current table

- Q: What are the different types of rail welds used with steel rails?

- There are several different types of rail welds commonly used with steel rails. These include: 1. Flash Butt Weld: This is the most common type of weld used in rail construction. It involves heating the rail ends using electric current and then pressing them together to create a seamless joint. Flash butt welding results in a strong and reliable bond between the rails. 2. Aluminothermic Weld: Also known as a thermit weld, this type of weld uses a chemical reaction to produce the necessary heat for joining the rail ends. A mixture of aluminum powder and iron oxide is ignited, creating a high-temperature reaction that melts the steel and forms a molten pool. The rail ends are then brought together and the molten metal solidifies to form a solid joint. 3. Gas Pressure Weld: This type of weld is used in situations where it is not possible to use flash butt welding or aluminothermic welding. Gas pressure welding involves heating the rail ends using a gas flame and then applying pressure to forge the ends together. This method requires skilled operators and special equipment to achieve a strong and reliable joint. 4. Electric Arc Weld: This method uses an electric arc to heat the rail ends and then applies pressure to forge them together. Electric arc welding is typically used for repairs and maintenance work, as it is less time-consuming and requires less specialized equipment compared to other welding methods. 5. Stud Welding: Stud welding is used to attach various accessories to the rail, such as guardrails, signals, or other fixtures. This type of welding involves shooting a stud or threaded bolt onto the rail surface using an electric arc. The stud is then securely attached, providing a strong connection for the accessory. Each type of rail weld has its own advantages and disadvantages, and the choice of which method to use depends on factors such as the specific application, location, and available resources. Proper welding techniques and quality control are essential to ensure the integrity and durability of rail welds.

- Q: How are steel rails protected from natural disasters (e.g., earthquakes)?

- Steel rails are built to withstand natural disasters such as earthquakes through a combination of engineering design and preventative measures. Firstly, the rails themselves are made from high-quality steel that is specifically designed to have a high tensile strength. This means that they have the ability to withstand strong forces and resist deformation during an earthquake. The steel used in rail construction is often reinforced with other materials like carbon or manganese, further enhancing its durability. In addition to the materials used, the design of the rail system plays a crucial role in protecting it from natural disasters. Rail tracks are carefully planned and constructed to ensure stability and minimize the impact of seismic activity. The tracks are typically laid on a solid foundation, which can include concrete, gravel, or even rock formations. This foundation provides a stable base for the tracks and helps distribute the forces generated during an earthquake. Furthermore, rail systems often incorporate specialized features to mitigate the effects of seismic events. For instance, engineers may install expansion joints, which allow the rails to expand and contract without causing significant damage. These joints help prevent the rails from buckling or breaking during temperature fluctuations or ground movements caused by earthquakes. Regular maintenance and inspections are also crucial in protecting steel rails from natural disasters. Railway authorities conduct routine checks to identify any signs of wear, corrosion, or damage that could compromise the integrity of the tracks. By promptly addressing these issues, they can ensure the safe operation of trains even in areas prone to earthquakes. Overall, the protection of steel rails from natural disasters like earthquakes is a result of a combination of factors including the quality of materials used, careful design and construction, incorporation of specialized features, and regular maintenance. These measures work together to minimize the impact of seismic activity and ensure the safety and reliability of rail transportation systems.

- Q: What are the benefits of using steel rails in freight transportation?

- There are several benefits of using steel rails in freight transportation. Firstly, steel rails provide a high level of durability and strength, allowing them to withstand heavy loads and frequent use without significant wear and tear. This results in a longer lifespan and lower maintenance costs compared to other materials. Secondly, steel rails offer excellent stability and track alignment, ensuring smooth and safe transportation of goods, reducing the risk of derailments or accidents. Additionally, steel rails have a high weight-bearing capacity, allowing for the transportation of larger and heavier cargo. Lastly, steel is a recyclable material, making it an environmentally friendly choice for freight transportation.

- Q: What are the safety features of steel rails?

- The safety features of steel rails include their strength and durability, which allow them to withstand heavy loads and prevent derailments. They also have a low coefficient of friction, providing stability and reducing the risk of accidents. Additionally, steel rails are designed with proper alignment and maintenance practices to ensure smooth and safe train operations.

- Q: How do steel rails impact fuel efficiency in trains?

- Trains benefit greatly from the presence of steel rails, as they significantly improve fuel efficiency. The use of steel rails enables the train to move more smoothly and efficiently, resulting in reduced energy consumption and improved overall fuel efficiency. Additionally, steel rails provide a stable and durable foundation for the train to travel on, minimizing the friction between the wheels and the tracks. This reduced friction means that the train faces less resistance, allowing it to move more easily and efficiently. Furthermore, steel rails are designed to maintain their shape and alignment under heavy loads, further enhancing fuel efficiency. By remaining stable, steel rails reduce the amount of energy required for the train to roll along the tracks, thereby conserving fuel. Moreover, the smoothness of steel rails allows for better distribution of weight and transfer of load across the train, which reduces strain on the locomotive. This, in turn, leads to reduced fuel consumption, as the train can operate at optimal speeds and power levels without wasting excessive energy. In addition, steel rails provide improved safety and stability, indirectly impacting fuel efficiency. With a reliable and secure track infrastructure, train operators can maintain consistent speeds while minimizing the need for sudden braking or acceleration. This steady and controlled movement not only reduces fuel consumption but also ensures a more efficient use of energy. Overall, steel rails play a crucial role in enhancing fuel efficiency in trains. By reducing friction, providing stability, and ensuring a smooth and safe travel experience, steel rails contribute to significant fuel savings, making trains an environmentally friendly mode of transportation.

- Q: How do steel rails contribute to train track alignment maintenance?

- Steel rails contribute to train track alignment maintenance in several ways. Firstly, steel rails provide stability and support to the tracks, ensuring that they remain aligned and in position. The strength and rigidity of steel rails help to prevent any lateral movement or misalignment of the tracks. Additionally, the smooth surface of steel rails reduces friction, allowing trains to travel smoothly and evenly along the tracks without causing any deviations or misalignments. Furthermore, steel rails are durable and resistant to wear and tear, minimizing the need for frequent maintenance and replacements, which aids in maintaining proper track alignment.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

High Quality HR Steel Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 25Tons m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords