Steel Heavy Rail GB2585-81 with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

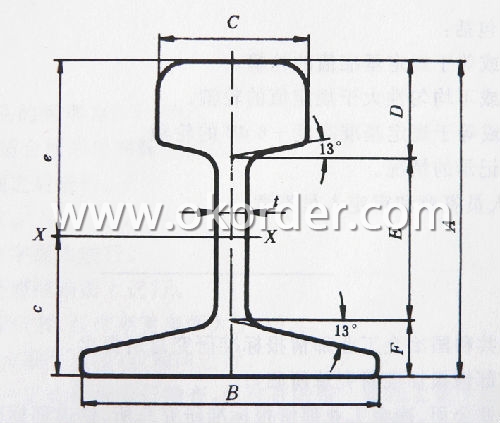

Specificaions of Steel Heavy Rail GB2585-81 with High Quality:

Production Standard: GB2585-81

Material: 50Mn, U71Mn

Grade | Element(%) | ||||

C | Mn | S | P | Si | |

50Mn | 0.48—0.56 | 0.70—1.00 | ≤0.035 | ≤0.035 | 0.17-0.37 |

U71Mn | 0.65—0.76 | 1.10—1.40 | ≤0.030 | ≤0.030 | 0.15-0.35 |

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Length: 10m, 12m, 12.5m or as the requriement of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Usage & Applications of Steel Heavy Rail GB2585-81 with High Quality:

Heavy Steel Rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel, can also be used for tower crane and other crane track.

For example: railway, subway, transportation track, express, curve way, tunnel way.

Packaging & Delivery of Steel Heavy Rail GB2585-81 with High Quality:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Ms Heavy Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Steel Heavy Rail GB2585-81 with High Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Are steel rails resistant to fire?

- Yes, steel rails are highly resistant to fire. Due to their high melting point and non-combustible nature, steel rails can withstand high temperatures and are less likely to ignite or be damaged by fire.

- Q: How do steel rails handle train-induced vibrations in nearby structures?

- Steel rails are designed to absorb and dissipate train-induced vibrations efficiently. The rigid and sturdy nature of steel rails helps in minimizing the transmission of vibrations to nearby structures. Additionally, rail fastening systems and resilient pads are used to further reduce vibrations and ensure the safety and stability of structures located in close proximity to the rail tracks.

- Q: What is the impact of steel rails on track maintenance costs?

- The use of steel rails has a significant impact on track maintenance costs. Steel rails are known for their durability and strength, which results in reduced wear and tear compared to other materials like wood or concrete. This leads to a longer lifespan for the rails, ultimately reducing the frequency of replacements and repairs. Additionally, steel rails have better resistance to extreme weather conditions, reducing the likelihood of damage caused by temperature changes or heavy rains. Consequently, the overall maintenance costs for tracks with steel rails are typically lower, allowing for more efficient and cost-effective operations.

- Q: How do steel rails contribute to the efficiency of railway systems?

- Steel rails contribute to the efficiency of railway systems in several ways. Firstly, steel rails provide a smooth and durable surface for train wheels to run on, minimizing friction and allowing trains to travel at high speeds with reduced energy consumption. Secondly, steel rails offer excellent strength and load-bearing capacity, ensuring the safe movement of heavy trains and enabling the transportation of large quantities of goods and passengers. Additionally, steel rails require minimal maintenance and have a long lifespan, reducing downtime and costs associated with repairs and replacements. Overall, steel rails play a crucial role in optimizing the efficiency and productivity of railway systems.

- Q: Can steel rails be reused in track maintenance projects?

- Yes, steel rails can be reused in track maintenance projects. They can be inspected, repaired if necessary, and then put back into service to extend their useful life and reduce costs.

- Q: Can steel rails be used for mining railways?

- Yes, steel rails can be used for mining railways. Steel rails are commonly used in mining operations due to their durability, strength, and ability to withstand heavy loads. They provide a stable track for transporting heavy mining equipment and materials efficiently and safely.

- Q: What are the factors considered in determining the appropriate steel rail length for a railway line?

- The factors considered in determining the appropriate steel rail length for a railway line include the desired speed and weight capacity of the trains, the curvature of the track, the terrain and elevation changes along the route, the expected traffic volume, and the level of maintenance and durability required.

- Q: Are steel rails used in mountainous terrains?

- Steel rails are frequently utilized for railway transportation in mountainous terrains. Renowned for their strength and durability, steel rails are suitable for challenging terrains like mountains. They are engineered to endure heavy loads and maintain stability on steep slopes. Furthermore, steel rails exhibit superior resistance to wear and tear, rendering them more dependable in mountainous regions plagued by harsh weather and rugged terrain. Consequently, steel rails are a crucial element of railway infrastructure in mountainous terrains, guaranteeing secure and efficient transportation.

- Q: How do steel rails handle the effects of heavy loads on bridges and tunnels?

- Steel rails are designed to handle heavy loads on bridges and tunnels by providing a durable and robust support system. Their high strength and stiffness allow them to distribute the weight of trains or vehicles evenly, minimizing the impact on the bridge or tunnel structure. Additionally, steel rails are resistant to wear, corrosion, and fatigue, ensuring their long-term reliability and ability to withstand heavy loads.

- Q: What are the specifications for steel rail expansion joints?

- The specifications for steel rail expansion joints typically include details such as the material composition, dimensions, load capacity, and installation requirements. These joints are designed to accommodate thermal expansion and contraction of the steel rails, ensuring safe and smooth movement of trains. The specifications may vary based on the specific railway system and the intended application of the expansion joints.

Send your message to us

Steel Heavy Rail GB2585-81 with High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords