Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

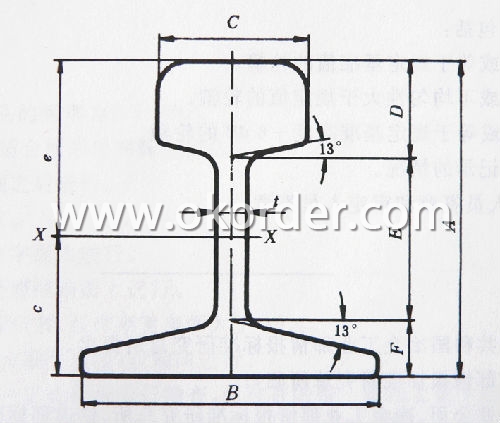

Specifications of Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260, etc.

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays

Images:

- Q: What are the noise levels produced by steel rails?

- The noise levels produced by steel rails can vary depending on several factors, including train speed, track condition, and surrounding environment. However, steel rails generally generate a significant amount of noise, especially when trains pass over joints or curves. Measures such as rail dampers, rail grinding, and track maintenance are often implemented to mitigate noise levels.

- Q: How do steel rails handle wear from train wheels?

- Steel rails handle wear from train wheels by being made of a strong and durable material that can withstand the constant rolling and grinding of the wheels. The steel used in rail tracks is specifically designed to have high hardness and resistance to wear, ensuring a long lifespan. Additionally, regular maintenance and inspection of the rails help to identify and address any signs of wear or damage, ensuring safe and smooth train operations.

- Q: What are the different types of rail joints used with steel rails?

- There are three main types of rail joints used with steel rails: the butt joint, the fish plate joint, and the welded joint. The butt joint involves two rail ends being placed closely together and supported by a plate underneath. The fish plate joint uses a pair of metal plates, known as fish plates, that are bolted on each side of the rail ends to connect them. The welded joint, on the other hand, involves the rail ends being fused together using a welding process, creating a continuous and seamless rail track.

- Q: How do steel rails handle expansion and contraction due to temperature changes?

- Steel rails are designed to handle expansion and contraction caused by temperature changes through the use of expansion joints and proper spacing between the rail tracks. This allows the rails to expand and contract freely without causing any significant damage or warping. Additionally, the steel material used in rails has a relatively low coefficient of thermal expansion, which helps to minimize the effects of temperature fluctuations.

- Q: How are steel rails inspected for fatigue cracks?

- Steel rails are inspected for fatigue cracks using various techniques such as ultrasonic testing, magnetic particle inspection, and visual inspection. Ultrasonic testing involves sending high-frequency sound waves through the rail to detect any internal flaws or cracks. Magnetic particle inspection uses magnetic fields and magnetic particles to identify surface cracks. Visual inspection is also carried out by trained inspectors who visually examine the rail for any visible signs of fatigue cracks.

- Q: How do steel rails handle heavy snowfall and ice?

- Steel rails are designed to withstand heavy snowfall and ice due to their durability and strength. The smooth surface of the rails minimizes the accumulation of snow and ice, reducing the risk of derailments. Additionally, railway operators use various methods such as snowplows, de-icing agents, and heating systems to ensure safe and uninterrupted train operations during winter conditions.

- Q: Are steel rails used in airport people movers?

- Yes, steel rails are commonly used in airport people movers. Steel rails provide a sturdy and reliable track system that allows the people mover to smoothly transport passengers between terminals, parking lots, and other areas within the airport. The use of steel rails ensures the safety of the passengers by providing a secure path for the people mover to travel on. Additionally, steel rails are durable and can withstand heavy loads, making them ideal for the constant movement of passengers and luggage in airport environments. Overall, steel rails are an integral component of airport people movers, providing a reliable and efficient means of transportation within the airport premises.

- Q: How are rail fractures repaired?

- Rail fractures are repaired by cutting out the damaged section of the rail and replacing it with a new piece. The process involves grinding the ends of the remaining rail to ensure a smooth fit, welding the new piece in place, and conducting thorough inspections to ensure the repair is sturdy and safe for train operations.

- Q: How do steel rails contribute to the reduction of wheel-rail contact fatigue?

- Steel rails contribute to the reduction of wheel-rail contact fatigue by providing a smooth and durable surface for train wheels to roll on. This minimizes the occurrence of wheel-rail contact stresses and the resulting fatigue damage. Additionally, steel rails are designed to distribute the load evenly, reducing the concentration of forces at specific points and preventing the development of cracks or fractures. Regular maintenance and inspection of steel rails also play a crucial role in identifying and addressing any potential issues before they escalate into contact fatigue problems.

- Q: How are steel rails protected from electrical damage?

- To protect steel rails from electrical damage, a process known as cathodic protection is utilized. This technique involves the placement of sacrificial anodes along the rail tracks, which are made from a metal that is more reactive than steel, such as zinc or magnesium. These anodes readily corrode, diverting any electrical current towards them instead of the steel rails. As a result, the steel rails remain unharmed by electrical damage. Furthermore, insulating materials can also be employed to safeguard steel rails from electrical harm. Insulators, such as rubber or plastic, can be positioned between the steel rails and any nearby electrical components or sources. By doing so, these materials prevent the flow of electrical current through the steel rails, effectively shielding them from potential damage. Moreover, it is vital to conduct regular maintenance and inspections of the rail tracks to promptly identify and address any potential electrical damage. Periodic examinations should be carried out to detect signs of corrosion or electrical faults, enabling preventive measures to be taken before the issues escalate. If any electrical damage is detected, immediate repairs or replacements should be undertaken to ensure the safety and integrity of the steel rails. Overall, a combination of cathodic protection, insulating materials, and regular maintenance is essential to protect steel rails from electrical damage. By implementing these measures, the railway infrastructure can be secured and dependent, minimizing the risk of electrical problems and ensuring the smooth operation of trains.

Send your message to us

Steel Light Rail Q235B, 55Q, Q345B, 50Mn, U71Mn, 900A, 1100, R260

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches