Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

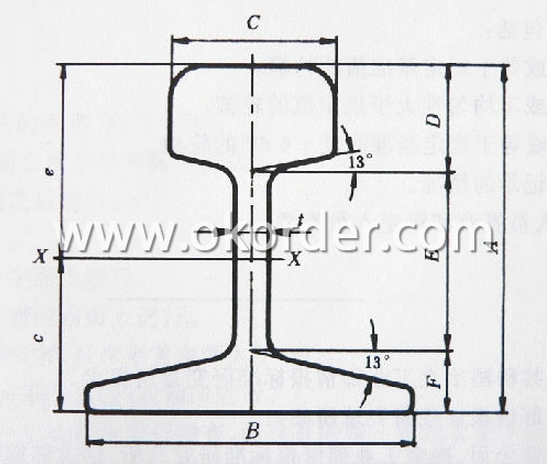

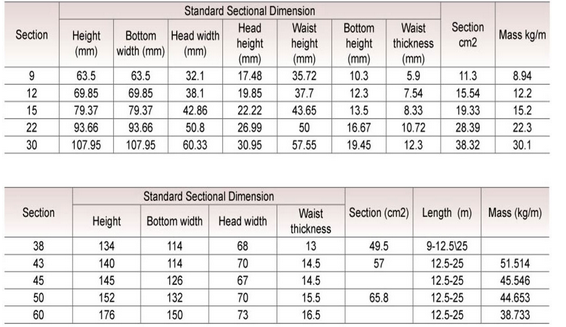

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Grade: 55Q

Sizes: 9kg-60kg

Length: 6M-25M as the requriement of the clients

Applications of Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Packaging & Delivery of Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Payment terms:30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

8. Others: Invoicing on theoretical weight or actual weight as customer request

Inspection of Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can fit in the containers of 20inches the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Are steel rails affected by earthquakes or other natural disasters?

- Yes, steel rails can be affected by earthquakes or other natural disasters. These events can cause ground shaking, which may lead to rail displacement, misalignment, or even complete destruction. It is important to assess and repair any damages to ensure the safety and functionality of the railway infrastructure.

- Q: What are the consequences of a cracked steel rail?

- The consequences of a cracked steel rail can range from minor disruptions to severe accidents and fatalities. A cracked rail compromises the structural integrity of the track, making it susceptible to derailments, which can result in train collisions, injuries, and even loss of life. It also leads to service disruptions, delays, and costly repairs. Therefore, addressing and fixing a cracked steel rail promptly is crucial to ensuring the safety and efficiency of railroad operations.

- Q: Can steel rails be used in railway systems with high-speed curves?

- Indeed, railway systems with high-speed curves can utilize steel rails. Steel is widely chosen as a material for railway tracks because of its robustness, power, and aptitude to endure substantial loads. The purpose of steel rails is to furnish stability and assistance to train wheels, thereby enabling them to traverse curves at high velocities without compromising safety. Furthermore, steel rails possess resistance against wear and tear, a vital characteristic in high-speed operations where trains exert substantial forces on the tracks. Nevertheless, it is important to acknowledge that certain adjustments and design considerations may be imperative to ensure accurate alignment and mitigate the likelihood of derailments in high-speed curves.

- Q: Can steel rails be used in curved tracks?

- Yes, steel rails can be used in curved tracks. The flexibility and durability of steel allow it to be bent and shaped to fit the desired curvature of the track, ensuring smooth and safe rail transportation even on curved sections.

- Q: How does the weight of steel rails affect their performance?

- The performance of steel rails is significantly impacted by their weight. A heavier rail generally provides greater stability and durability, reducing the likelihood of wear and deformation. The weight of the rail helps evenly distribute the load of passing trains, decreasing the risk of rail buckling or bending. Additionally, the weight of steel rails affects their ability to handle heavy loads and maintain track alignment. Heavier rails offer better resistance to lateral forces, ensuring that the track remains straight and aligned, even under the pressure of passing trains. This is particularly important for high-speed rail systems or tracks with heavy freight traffic. Furthermore, the weight of steel rails plays a critical role in determining their ability to withstand fatigue and maintain structural integrity over time. Heavier rails have higher resistance to fatigue caused by the repeated stress of trains passing over the track. This prolongs the rail's lifespan and reduces the need for frequent maintenance or replacement. However, it is crucial to find a balance between the weight of the rail and other factors such as track design, rolling stock, and operating conditions. If the rail is too heavy, it may increase overall costs of the railway system, requiring more material and energy for production, transportation, and installation. Moreover, the weight of the rail can impact the energy consumption of trains, as heavier rails increase rolling resistance. In conclusion, the weight of steel rails directly impacts their stability, durability, load-bearing capacity, track alignment, fatigue resistance, and maintenance requirements. Determining the optimal weight for rails involves considering various factors and striking a balance between performance, cost-effectiveness, and energy efficiency.

- Q: Can steel rails be used for tramways?

- Tramways can indeed utilize steel rails. In truth, steel rails are frequently employed for tramways owing to their exceptional endurance, robustness, and capacity to bear substantial burdens. Steel rails furnish a seamless and steadfast pathway for trams, guaranteeing secure and efficient transportation. Moreover, steel rails demand lesser upkeep in comparison to alternative materials, rendering them an economical selection for tramway systems.

- Q: How do steel rails contribute to reducing track geometry irregularities?

- Steel rails contribute to reducing track geometry irregularities by providing a strong and stable foundation for trains to run on. The durability and rigidity of steel rails help maintain the correct alignment and level of the track, minimizing deviations and maintaining a smooth and even surface for trains to travel on. This reduces the occurrence of track geometry irregularities such as misalignment, unevenness, and excessive wear, ensuring safer and more efficient train operations.

- Q: High speed rail runs so many trains a day, what about rail wear?

- The track is regularly checked and repaired. These are upstairs, in addition, the EMU because the car is light, but also the whole car power, the rail wear is not large, there is no heavy haul trains. What's more, its curves and downhill slopes have been computed without any large downhill or small radius curves. Secondly, high-speed rail or rail lines or, in addition to rail bottom slope on rail surface will advance and regular grinding, in order to form a point of view, the train is running, but can improve the wheel through smoothly.

- Q: How are steel rails secured to the railway bed?

- A combination of fasteners and fittings is typically utilized to secure steel rails to the railway bed. This process comprises several steps to guarantee the firm attachment of the rails and their ability to withstand the weight and movement of trains. To begin with, the railway bed is prepared by leveling the ground and compacting it, providing a stable foundation. Subsequently, a layer of ballast, usually consisting of crushed stones, is placed on top of the bed. This ballast serves to distribute the weight of the trains and facilitate drainage. Once the bed is prepared, the steel rails are positioned on the ballast. These rails are usually manufactured in long sections and are connected together using specialized connectors known as fishplates or splice bars. These connectors are either bolted or welded to the ends of adjacent rails, creating a continuous track. Various types of fasteners are employed to secure the rails to the railway bed. One common method involves the use of elastic rail clips, which are affixed to the sides of the rails and connected to the railway sleepers (ties) using spikes or screws. The elasticity of these clips aids in absorbing vibrations and maintaining tension in the rail system. Resilient pads are also utilized as a means of securing the rails. Positioned between the rails and the sleepers, these pads act as a cushion, absorbing shocks and vibrations. Typically composed of rubber or synthetic materials, they contribute to reducing wear and tear on the rails. Additionally, rail anchors and rail braces may be employed as fittings to enhance stability and prevent lateral movement of the rails. Rail anchors are devices placed between the rails and the sleepers, providing additional grip and preventing rail shifting. Rail braces, on the other hand, are used to ensure proper alignment and spacing of the rails. In summary, the process of securing steel rails to the railway bed necessitates the use of connectors, fasteners, and fittings. This comprehensive approach ensures the secure attachment of the rails, enabling safe and efficient train operations.

- Q: How do steel rails withstand heavy traffic loads?

- Due to its unique properties and design, steel rails can withstand heavy traffic loads. Firstly, steel is renowned for its high strength and durability, making it an optimal material for constructing railway tracks. Rails are specifically engineered to have a high tensile strength, enabling them to resist deformation and endure significant forces without breaking. Moreover, steel rails are ingeniously designed to evenly distribute the weight of trains, minimizing the impact on any particular section of the track. This is achieved through the utilization of continuous welded rails, where long sections of rail are seamlessly joined without any gaps. This ensures a smooth and uninterrupted surface for trains to travel on, reducing the concentration of stress at any given point. Additionally, steel rails are supported by sturdy and stable sleepers or ties, which provide a solid foundation for the track. These sleepers, typically made of concrete or wood, are placed at regular intervals along the track, effectively distributing the load and preventing excessive bending or deformation of the rails. Regular maintenance and inspections are also crucial in guaranteeing the durability and safety of steel rails. Inspections are carried out to identify any signs of wear, fatigue, or damage, and repairs or replacements are promptly executed when necessary. This proactive approach helps prevent catastrophic failures and ensures the uninterrupted operation of the railway system. In conclusion, the combination of steel's strength, the design of the rails and sleepers, and regular maintenance all contribute to the exceptional ability of steel rails to withstand heavy traffic loads. This enables trains to travel safely and efficiently, even under the most demanding circumstances.

Send your message to us

Hot Rolled Mild Light Steel Rail for Minas Q235,55Q Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords