Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light rail is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Product Advantages:

OKorder's Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

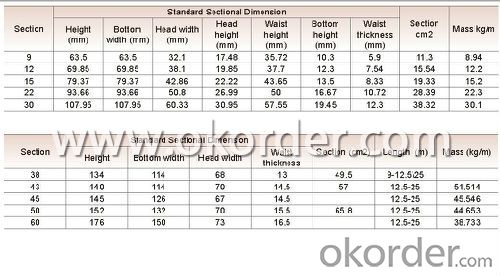

Specifications of Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines:

Product Name: Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

Production Standard: GB, AREMA, JIS, DIN, EN, UIC, BS, etc.

Grade: Q235B, 55Q, 900A, 1100A, 50MN, U71MN, R260.

Place of Origin: China

Length: 6M-24M according to the requriements of the customers.

Packaging & Delivery of Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

7. Invoicing on theoretical weight or actual weight as customer request

8. Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Inspection of Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

We will send the MTC of the factory to the clients directly which contains the anlisis of the heat, chemiqual composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can fit in the containers of 20inches the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:Are steel rails used in industrial applications?

- Indeed, in industrial applications, steel rails are frequently employed. Renowned for their strength, durability, and resistance to abrasion, they prove ideal for demanding industrial purposes. Their utilization in railway track construction is extensive as they provide a sturdy and dependable base for the movement of trains and other transportation vehicles. Furthermore, within factories, warehouses, and ports, where the transportation or relocation of heavy machinery and equipment is required, steel rails are also utilized. In summary, steel rails are indispensable in industrial applications, offering a secure and effective means of transporting goods and materials.

- Q:How do steel rails contribute to energy efficiency in transportation?

- Steel rails contribute to energy efficiency in transportation in several ways. Firstly, steel rails provide a smooth and low-friction surface for trains to travel on, reducing the amount of energy required to move the train. This allows trains to operate with less energy consumption compared to other modes of transportation like trucks or cars. Additionally, steel rails have a longer lifespan compared to other materials, such as wood or concrete, reducing the need for frequent replacement and maintenance. This leads to lower energy and resource consumption in the long run. Overall, the use of steel rails in transportation helps to minimize energy waste and promote more sustainable and efficient transportation systems.

- Q:What are the dimensions of standard steel rails?

- The dimensions of standard steel rails typically vary depending on the specific rail profile. However, a common dimension for standard steel rails used in railway tracks is a length of 39 feet and a weight of 115 pounds per yard.

- Q:What is the maximum load capacity of a steel rail?

- The maximum load capacity of a steel rail depends on various factors such as its dimensions, quality, and design. It can range from a few tons to several hundred tons, depending on the specific application and intended use.

- Q:How are steel rails protected from theft?

- Steel rails are protected from theft through various measures, including the use of security cameras, fencing, and alarms. Additionally, some railroads employ specialized security personnel to monitor and patrol the rail lines. Furthermore, the steel rails may be marked with unique identification numbers or have tracking devices installed to deter theft and aid in recovery if stolen.

- Q:How are steel rails designed to handle heavy loads?

- Steel rails are designed to handle heavy loads by incorporating a combination of strength, durability, and flexibility. They are typically made from high-quality steel, which has high tensile strength and can withstand immense pressure. The rails are carefully engineered to have specific dimensions and cross-sectional shapes that distribute the load evenly and minimize stress concentration. Additionally, they undergo various heat treatments and manufacturing processes to enhance their hardness and resistance to wear and fatigue. The rails are also designed with a specific profile, including a curved shape, to facilitate smooth movement of trains and reduce the impact of heavy loads. These design elements collectively ensure that steel rails can efficiently support and withstand the weight and force exerted by heavy trains.

- Q:Can steel rails be used in curved track sections?

- Yes, steel rails can be used in curved track sections. In fact, steel rails are widely used in railway tracks, including curved sections. Steel rails have several advantages that make them suitable for curved tracks. Firstly, steel is a durable and strong material, capable of withstanding heavy loads and high speeds. This makes steel rails ideal for curved sections where the tracks are subjected to increased stress and forces. Additionally, steel rails can be manufactured in various lengths and shapes, allowing for flexibility in designing and constructing curved tracks that match the specific requirements of the rail network. Moreover, steel rails can be easily welded together, enabling seamless and smooth transitions between straight and curved sections of the track. Overall, the use of steel rails in curved track sections ensures stability, safety, and efficient transportation along the railway system.

- Q:What are the different types of rail grinding techniques used with steel rails?

- There are primarily two types of rail grinding techniques used with steel rails: preventive grinding and corrective grinding. Preventive grinding involves regular grinding of the rail surface to remove small defects and maintain the desired rail profile. This technique helps to prevent the formation of more severe defects and prolongs the rail life. On the other hand, corrective grinding is performed to address specific defects like rail corrugation, surface cracks, or excessive wear. This technique aims to restore the rail profile and improve the ride quality and safety of the track.

- Q:How do steel rails contribute to energy efficiency in rail transportation?

- Steel rails contribute to energy efficiency in rail transportation in several ways. Firstly, steel rails provide a smooth and stable surface for the train wheels, reducing friction and rolling resistance. This allows trains to move more efficiently, requiring less energy to overcome resistance and maintain speed. Additionally, steel rails have high durability and wear resistance, resulting in less maintenance and replacement needs. This leads to reduced downtime and increased operational efficiency, ultimately saving energy that would otherwise be required for maintenance activities. Moreover, the weight of steel rails plays a crucial role in energy efficiency. Heavier steel rails provide better stability and reduce vibration, allowing trains to travel at higher speeds while maintaining safety. This eliminates the need for excessive braking and acceleration, which consume significant amounts of energy. Overall, the use of steel rails in rail transportation promotes energy efficiency by minimizing rolling resistance, reducing maintenance requirements, and providing stability for efficient train operation.

- Q:Can steel rails be used for military transport systems?

- Yes, steel rails can be used for military transport systems. Steel rails are commonly used for railway infrastructure, including military railways, as they provide a sturdy and reliable foundation for transporting heavy equipment and troops. These rails are capable of supporting the weight of military vehicles, allowing for efficient and secure transportation of personnel and supplies in various terrains. Additionally, steel rails can be easily repaired and maintained, making them suitable for military operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mild Hot Rolled Light Steel Rail Q235, 55Q for Mines

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords