Steel Heavy Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Heavy Rail

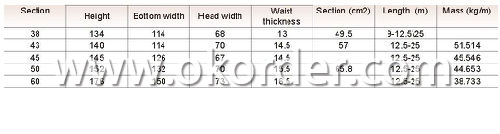

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Steel Heavy Rail

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Tunnel way, curve way, railway, subway, transportation track, express, etc.

Package & Delivery of Steel Heavy Rail

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, grade, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Steel Heavy Rail

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

Production flow of Steel Heavy Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: What is the process of straightening bent steel rails?

- To restore the original shape and structural integrity of bent steel rails, multiple steps are involved in the straightening process. To begin with, a thorough examination of the bent rail is conducted to assess the extent of the damage and determine the most suitable approach for straightening. This evaluation is crucial in identifying any additional issues, such as cracks or fractures, that may require attention during the process. Subsequently, a specialized hydraulic straightening press is utilized to apply controlled and gradual pressure to the bent section of the rail. This press is designed to distribute force evenly across the rail, minimizing the risk of further damage or distortion. Prior to straightening, it is common practice to heat the rail to enhance its malleability and facilitate the straightening process. Once the rail is appropriately positioned in the press, the hydraulic system is activated to gradually apply pressure to the bent section. The pressure is adjusted based on the severity of the bend and the specific type of rail being straightened. The objective is to gradually exert force until the rail regains its original shape without causing any additional harm. Throughout the straightening process, periodic heating of the rail may be necessary to maintain its malleability and prevent cracking. The method of heating employed depends on the type of rail and its specific requirements, with options including induction heating or oxy-acetylene torches. Following the straightening procedure, a thorough inspection is conducted to ensure that the rail meets the required specifications and standards. This inspection involves checking for any remaining deformities, cracks, or defects that may have occurred during the straightening process. Finally, the straightened rail often undergoes stress testing or non-destructive testing methods, such as ultrasonic or magnetic particle inspection, to further verify its structural integrity and suitability for use. In conclusion, the process of straightening bent steel rails is a meticulous and precise procedure that demands expertise, specialized equipment, and careful evaluation to successfully restore the rail to its original shape and strength.

- Q: What is the purpose of steel rails?

- The purpose of steel rails is to provide a stable and durable track for trains and other heavy vehicles, enabling efficient and safe transportation.

- Q: What are the safety measures for workers during steel rail repairs?

- During steel rail repairs, it is crucial to prioritize the safety of workers. Here are some essential safety measures that should be implemented: 1. Adequate training: Workers should receive proper training on the specific procedures and techniques involved in steel rail repairs. This includes understanding the use of tools and equipment, as well as safety protocols. 2. Personal Protective Equipment (PPE): Workers should be provided with appropriate PPE such as hard hats, safety glasses, high-visibility clothing, steel-toed boots, and gloves. These protective gears help minimize the risk of head injuries, eye injuries, slips, trips, and falls. 3. Hazard identification and control: A thorough risk assessment should be conducted before starting any repair work. Identifying potential hazards such as sharp edges, electrical hazards, or exposure to hazardous substances is essential. Necessary control measures should be implemented to eliminate or minimize these risks. 4. Safe access and egress: Workers should be provided with safe access and egress points to the work area. This includes properly maintained walkways, stairs, and ladders, as well as ensuring adequate lighting to prevent trips and falls. 5. Lockout/tagout procedures: If repair work involves electrical equipment, lockout/tagout procedures should be followed to ensure that all energy sources are isolated and de-energized, reducing the risk of electrical shocks or electrocution. 6. Ventilation and respiratory protection: If workers are exposed to fumes, dust, or other airborne contaminants during steel rail repairs, proper ventilation systems should be in place. If necessary, respiratory protection equipment should be provided to prevent inhalation of hazardous substances. 7. Communication and coordination: Clear communication and coordination among workers are vital to ensure their safety. This includes regular safety briefings, proper signage, and effective communication mechanisms to report any potential hazards or incidents. 8. Emergency preparedness: Emergency response plans should be in place, and workers should be familiar with evacuation routes, assembly points, and the use of fire extinguishers. First aid kits and emergency contact information should be readily available at the worksite. 9. Regular inspections and maintenance: Regular inspections of tools, equipment, and work areas should be conducted to identify any potential hazards or defects. Any issues should be promptly addressed to maintain a safe working environment. 10. Ongoing safety training and awareness: It is essential to provide regular safety training and promote a culture of safety among workers. This includes reminding them of safety procedures and encouraging them to report any safety concerns or near misses. By implementing these safety measures, the risk of accidents, injuries, and health hazards can be significantly reduced during steel rail repairs, ensuring the well-being of workers.

- Q: How are steel rails protected from soil erosion?

- Steel rails are typically protected from soil erosion through a combination of preventive measures and regular maintenance. One of the primary methods used to prevent soil erosion around steel rails is the placement of ballast, which is a layer of crushed stones or gravel that is spread around the tracks. The ballast serves multiple purposes, including providing stability and support to the rails, allowing for proper drainage, and reducing the impact of water runoff. Additionally, proper drainage systems are installed to redirect any excess water away from the rail tracks, minimizing the risk of erosion. This can include the construction of ditches or culverts to ensure that water does not accumulate near the tracks. Regular maintenance is also crucial in protecting steel rails from soil erosion. Inspections are conducted to identify any signs of erosion or damage, such as washouts or loose ballast, and necessary repairs are promptly carried out. This proactive approach helps to prevent further erosion and ensures the safety and longevity of the rail infrastructure. In summary, steel rails are protected from soil erosion through the use of ballast, proper drainage systems, and regular maintenance practices. These measures work together to maintain the stability and integrity of the rail tracks, preventing erosion and ensuring the efficient functioning of the railway system.

- Q: What are the different surface finishes available for steel rails?

- The different surface finishes available for steel rails include plain, polished, galvanized, and painted finishes.

- Q: Are steel rails used in mining railways?

- Steel rails are often employed in mining railways because of their high strength and durability. They are perfectly suited for the demanding conditions and heavy loads encountered in mining operations. These rails offer a stable and dependable track system capable of supporting locomotives and ore cars carrying substantial mineral quantities. Moreover, steel rails are resistant to wear and deformation, reducing the need for frequent maintenance and replacement. This cost-effective solution is favored by mining companies as it can withstand the challenging mining conditions while facilitating efficient transportation of extracted materials.

- Q: Can steel rails be used in railway sidings or spurs?

- Yes, steel rails can be used in railway sidings or spurs. Steel rails are commonly used in railway tracks due to their durability, strength, and ability to withstand heavy loads. Railway sidings or spurs are essentially additional tracks branching off the main railway line, and steel rails are suitable for these applications as well.

- Q: What are the environmental regulations associated with steel rail production?

- The environmental regulations associated with steel rail production are aimed at reducing the harmful impacts of this industrial process on the environment. These regulations vary depending on the country and region, but generally focus on several key areas. Firstly, air emissions control is a significant aspect of environmental regulations for steel rail production. This includes standards for controlling emissions of pollutants such as particulate matter, sulfur dioxide, nitrogen oxides, and carbon monoxide from the various stages of steel production, including the melting and rolling processes. Steel producers are required to install and maintain pollution control technologies like baghouses, electrostatic precipitators, and scrubbers to reduce these emissions. Water pollution prevention is another critical concern in the steel rail production industry. Regulations require companies to implement measures to prevent water contamination from the production process. This may involve treating wastewater, monitoring discharges, and implementing best management practices to minimize the release of pollutants like heavy metals, oil, and grease into water bodies. Waste management is also tightly regulated in steel rail production. Steel producers must follow guidelines for the proper handling, storage, and disposal of solid and hazardous waste generated during the manufacturing process. This includes recycling and reusing materials wherever possible and ensuring that any waste disposed of is done so in accordance with environmental regulations. Energy efficiency is a growing focus in environmental regulations associated with steel rail production. Countries are setting energy consumption benchmarks and encouraging steel producers to adopt energy-efficient technologies and practices to reduce their carbon footprint. This may include using more energy-efficient furnaces, optimizing production processes, and investing in renewable energy sources. Furthermore, environmental regulations often require steel producers to conduct environmental impact assessments and develop environmental management plans to ensure compliance with all relevant regulations. Regular monitoring and reporting of environmental performance is also typically mandated. Overall, the environmental regulations associated with steel rail production aim to minimize air and water pollution, manage waste effectively, conserve energy, and promote sustainability in the industry. By complying with these regulations, steel producers can mitigate their environmental impact and contribute to a cleaner and more sustainable future.

- Q: How do steel rails affect train speed and stability?

- The speed and stability of trains are greatly influenced by steel rails. Firstly, the smooth and durable surface of steel rails enables trains to travel at high speeds without causing excessive wear on the wheels and tracks. This reduced friction allows trains to maintain higher velocities, resulting in faster travel times. Furthermore, steel rails provide a secure and reliable track system that ensures stability for the train. The rigid structure of steel rails allows trains to navigate the tracks smoothly, minimizing the risk of derailment or accidents. Steel's high strength and resilience also distribute the weight of the train evenly, preventing any uneven pressure on the tracks that could destabilize the train. Moreover, the design of steel rails, including their shape and size, plays a role in train stability. The rails are meticulously engineered to offer optimal support and guidance to the train wheels, reducing the chances of swaying or veering off track. This enables the train to stay on its intended path, enhancing stability during acceleration, deceleration, and while navigating curves. In conclusion, steel rails have a significant impact on train speed and stability. They allow trains to achieve higher speeds while maintaining a smooth and reliable track system. By providing stability and guidance to the train, steel rails contribute to safe and efficient train travel.

- Q: How do steel rails handle seismic activity?

- Steel rails are designed to withstand seismic activity to a certain extent. The flexibility and strength of steel allow it to absorb and distribute the energy generated during an earthquake, reducing the risk of rail failure. Additionally, modern construction techniques and advanced materials ensure that steel rails can withstand ground shaking, lateral forces, and other seismic effects, making them highly resilient and capable of maintaining their integrity during seismic events.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Steel Heavy Rail

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords