Conveyor Rail

Conveyor Rail Related Searches

Crane Rail Inclined Conveyor Belt Rail Crane Portable Belt Conveyors Small Conveyor Belt Systems Van Cargo Rail Conveyor Belt Idlers Rail Cutter Moving Truck Metal Cast Iron Cargo Van Monorail Hoist Kmart Trolley Iron Tubes Conveyor Belt Vulcanizing Press Rayon Yarn Alloy Cast Iron Moving Tape Rail Mounted Gantry Broken Cast Iron Van Cargo Contraction Equipment Cargo Caddy Mottled Cast Iron Crane Lifting Cargo Van Shelving Cast Iron Metallurgy Cast Iron Foundry Cast Iron Fence Sewing YarnConveyor Rail Supplier & Manufacturer from China

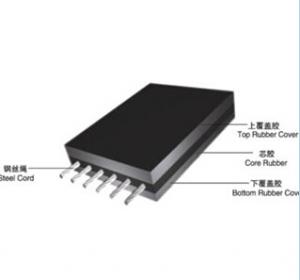

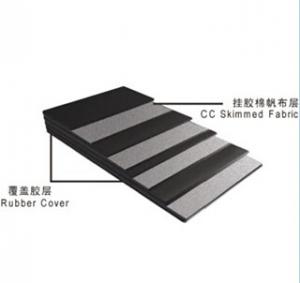

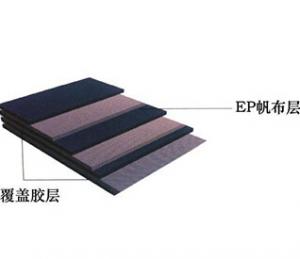

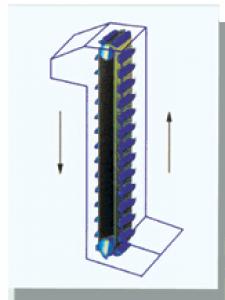

Conveyor Rail is a crucial component in various material handling systems, designed to guide and support the movement of conveyor belts. These rails come in different materials, such as steel, aluminum, and plastic, and are engineered to withstand heavy loads while ensuring smooth and efficient operation. They are widely used in industries like manufacturing, warehousing, and logistics to transport goods from one point to another, enhancing productivity and reducing manual labor.In numerous industrial settings, Conveyor Rail plays a vital role in streamlining operations. It is used in assembly lines, packaging processes, and material sorting systems, where it helps in the efficient movement of products and components. The rails are designed to accommodate different types of conveyor belts, such as flat, troughed, or cleated belts, depending on the specific requirements of the application. This versatility allows for customized solutions that can be tailored to fit the unique needs of each industry.

Okorder.com is a reputable wholesale supplier of Conveyor Rail, boasting a large inventory that caters to the diverse needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Conveyor Rail products they offer meet the highest standards of durability and performance. Their extensive range of Conveyor Rail solutions makes them a one-stop-shop for businesses looking to optimize their material handling processes.

Hot Products