Flame Resistant Conveyor Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Flame Resistant Conveyor Belt

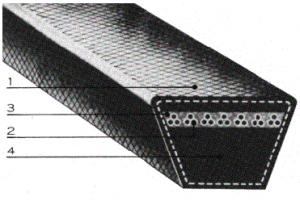

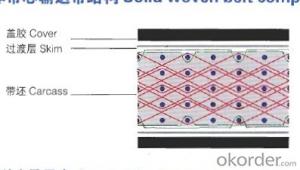

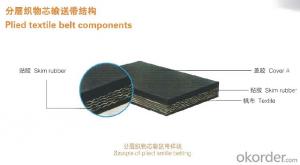

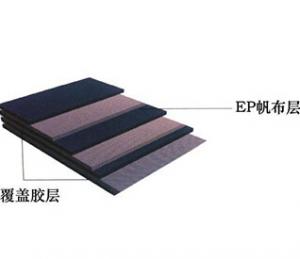

1.Carcass:EP,CC,NN

2.Tensile Strength:100~2400N/mm

3.Rubber:Resistant wear,heat,oil

ISO9001:20

Flame resistant conveyor belt enhance safety for personal, provide life cycle cost advantages,

ensure a long belt life. Compliance with the most stringent safety requirements and products of highest

quality essential for reliable performance under the most demanding operating conditions.

Fire and safety requirements for fabric conveyor belts for use in underground coall mines | ||||||||

Standard | Belt Grade | Resistivity Electrical resistance of covers | Drum friction test Ignitability and maximum surface temperature of belting subjected to friction Test method acc. to MT830-2008 | Alcohol blast burn test Ignitability and flame propagation characteristics Test method acc. to MT830-2008 | Gallery test Combustion propagation characteristics Test method acc. to MT830-2008 | |||

Frame | Glow | Max. surface temperature | Permissible flame duration | |||||

With covers | Without covers | |||||||

MT830-2008 | “S” | ≤ 3.0*108Ω | Not permitted | Not permitted | 325℃ | Each single sample< 10 sec Average of all samples <3 sec | Each single sample <15 sec Average of all samples <5 sec | Minimum undamaged length of 600mm over full width |

MST® flame resistant conveyor belt are primarily used in the following industries:

· Coal-fired powder stations,

· Biomass power stations,

· Fertilizer industry

· Wood processing industry,

· Port operations,

· Open-cast minings,

· Wast incineration plant

Carcass | Belt width mm | No. of Plies | Thickness of cover Top Bottom | |

EP100 EP125 | 300 | 3~5 | 4.5 3.0 1.5 | 3.0 1.5 |

EP100 EP125 | 400 | 3~6 | 4.5 3.0 1.5 | 3.0 1.5 |

EP100 EP125 | 500 | 3~6 | 4.5 3.0 1.5 | 3.0 1.5 |

EP100 P125 | 600 | 3~6 | 4.5 3.0 1.5 | 3.0 1.5 |

EP100 EP125 | 650 | 3~6 | 4.5 3.0 1.5 | 3.0 1.5 |

EP125 EP200 | 800 | 3~6 | 6.0 4.5 3.0 1.5 | 3.0 1.5 |

EP150 EP200 | 1000 | 3~8 | 6.0 4.5 3.0 1.5 | 4.5 3.0 1.5 |

EP150 EP200 | 1100 | 4~10 | 6.0 4.5 3.0 | 4.5 3.0 1.5 |

EP150 EP200 | 1200 | 4~10 | 6.0 4.5 3.0 | 4.5 3.0 1.5 |

EP150 EP200 | 1400 | 4~10 | 6.0 4.5 3.0 | 4.5 3.0 |

EP200 EP250 | 1600 | 5~10 | 6.0 4.5 | 4.5 3.0 |

Cover Rubber Grade | Tensile Strength Mpa | Elongation at Break % | Abrasion mm3 |

H | 24 | 450 | 120 |

D | 18 | 400 | 100 |

L | 15 | 350 | 200 |

* meet to GB/T 7984-2001standard equal to ISO/FDISI4890-99 standard

- Q: How do you remove the gasoline from the rubber band?

- Hardware store, where you can buy paint, 5 dollars a small bottle. Give in cloth, repeatedly rub, rub a few will be able to erase. Tips: hand in a plastic bag, or to buy the duck to several gloves, don't get thinner on the hand, will corrode the skin.

- Q: How about white rubber strap yellowing?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q: What is the essential difference between the effect of electric tape and rubber band?

- High tension self adhesive tape refers to the rubber belt. It is of great elasticity. It is used in the distribution box, grounding and bridge span.

- Q: What's the rubber band on your wrist when you play basketball?

- Theoretically, it prevents perspiration, prevents sweat from flowing down the arm, makes the hands slip and throws the ball

- Q: The difference between roller printing machine and rotary screen printing machine

- Round screen printing is a kind of printing method that uses the scraper to print the paste in the circle net under pressure. There are several important aspects of rotary screen printing, which are different from other screen printing methods. Rotary screen printing and printing roller, Department of continuous process, printing fabric by wide rubber band is transported to the continuous movement of the rotary cylinder. The principle and the roller opposite to its, is in the round net (nickel net) as internal extravasation (by scraper, bar and slurry pressure) to complete printing;

- Q: White rubber strap dirty, how to do?

- Now clean the strap. Clean the surface of the strap first, then clean the stain in the band gap. The gaps are so tight that it's difficult to clean the dirt inside. Now the gaps are opened up by the cylinder, and the dirt can be cleaned.

- Q: JSP what does water swelling rubber belt mean?

- Water swellable rubber sealing strip is imported with special rubber as the main raw material, with a rubber strip products of inorganic absorbent, high viscosity resin and so on more than ten kinds of special material by mixing, mixing, extrusion and the.

- Q: Where can I buy 3mm thick rubber belts, black ones? Best to explain the price per square meter

- Of course, no more than 500 dollars a flat. Hope to help you. I think you have to make sure what the material is. First of all, I hope I can help you.

- Q: What is the role of the rubber band Caoguan vehicle above

- Electrostatic guided rubber traction belt is mainly used for transporting dangerous chemicals in tanks, tanks, cars, tanks, car shelves, electric static rubber and towing belts. It can prevent fire accidents caused by static electricity

- Q: The rubber strap is a little tight, is it better or a little loose?

- The watch is no longer a ticking tool today. Your wrist is very thin, so I'll tell you what I know about trying to stretch on the elastic.

Send your message to us

Flame Resistant Conveyor Belt

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords