NYLON CONVEYOR BELT-Plied textile conveyor belts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

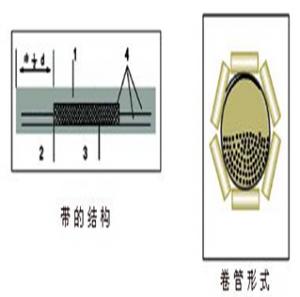

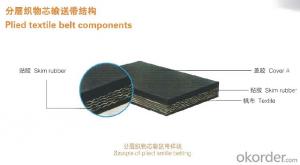

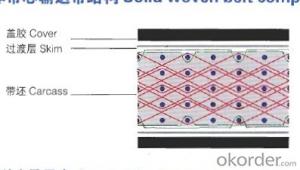

polyamide).Bonding interlay rubber and cover rubbe rduring calendering process,finished after vulcanization process.

NYLON CONVEYOR BELT

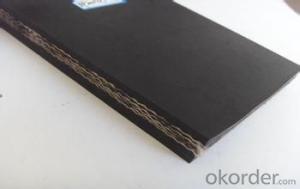

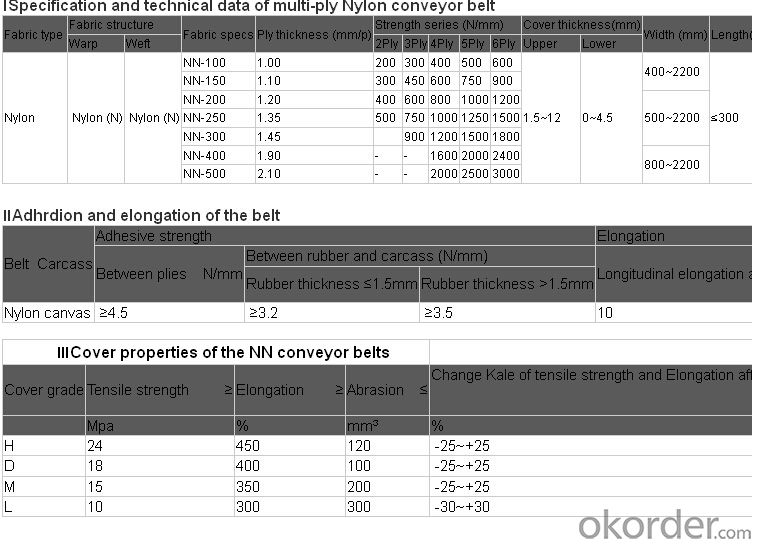

The nylon conveyor belt is made with the nylon canvas woven with polyamide fiber as the framework material and coated with rubber of high performance. It has the features of thin belt carcass, high tensile strength, abrasion proof, impact-resistance, strong adhesion between layers, good traction, and long service life. It is suitable to convey materials in medium and long distance, high-load and at high speed, and finds wide applications in mines, metallurgy, construction, and ports.

- Q: Why is the watch of rubber band more expensive than resin?

- PS: rubber contains a variety of ingredients, a pungent odor, some of which may have an impact on human health, so generally contact the skin and long-term contact will use silicone.

- Q: Why are the engines almost all rubber belts?

- All kinds of driving methods have their own advantages and disadvantages.Sprocket, chain drive - transfer speed is limited.Gear transmission --- the transmission distance is limited and the noise is great.Belt drive - smooth transmission, quiet, easy to implement, low cost.

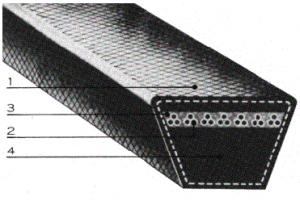

- Q: Conveyor rubber belt welding

- The conveyer belt is composed of reinforcing material (core), core material (adhesive), covering rubber and adhesive.(1) reinforced material (belt core): it is the key of conveyor belt bearing, it determines the tensile strength of conveyor belt, and can absorb the impact of material on conveyor belt.(2) core material (adhesive): it has good adhesive strength between the reinforcing material and fabric layer, and prevents the lamination of the core during use.(3) covering rubber: it has the functions of protecting and reinforcing material, transmitting power, conveying material, absorbing material and resisting abrasion.(4) side rubber: protect the reinforced material from erosion by medium, absorb the extrusion force from the side of conveyer belt, prevent the lamination of core.

- Q: What sectors does rubber drive? That is to say, what are the main uses of rubber?

- There are many kinds of rubber, depending on what kind of rubber, each kind of rubber has its own use, can not be generalized.

- Q: What is the essential difference between the effect of electric tape and rubber band?

- Electrical tape refers to the PVC material. Polyvinyl chloride film coated with pressure sensitive adhesive. Generally used in automobile maintenance, wire and cable terminals and intermediate joints insulation protection, acquaintance, color separation, sheath protection, wiring harness.

- Q: What's the rubber band on your wrist when you play basketball?

- It means the player's message strip, usually with the name of the player, the team and the number, but we are not professional players, so take that as a decoration

- Q: The difference between roller printing machine and rotary screen printing machine

- Roller printing is a kind of printing process with copper rollers with concave patterns. It is also called copper roll printing. The drum is referred to as cylinder engraving. When printing, the cylinder surface coated with paste, with sharp and flat blade will not cut part of the cylinder surface paste scraping, the concave pattern is reserved in the paste. When the cylinder imprint on the fabric, color transfer to the fabric and printing patterns. Each cylinder of a printing paste, such as printing equipment and equipped with multi cylinder, which can continuously print color patterns. Roller printing in parts of the country also known as iron printing, the principle of consistent with our daily stamp;

- Q: How should the rubber strap be cleaned and maintained?

- If you need to wash the strap, it is recommended to add detergent water soak for about 15 minutes, and then immerse in cold water for about 15 minutes.

- Q: JSP what does water swelling rubber belt mean?

- Water in the water will gradually swell in water, will eventually slow jam, the existence of pores in concrete and the interface contact more closely, resulting in high water pressure resistance, the formation of impermeable plastic colloid, this product has a high inflation rate, mobile added performance. In the construction joint seam, with balanced self-healing function strong, self sealing for settlement and the emergence of a new small gap, has completed the project, such as Water Leakage available water infiltration through the gaps, re plugging, low construction cost and simple construction process, excellent corrosion resistance.

- Q: How to clean rubber band?

- 1. Soak it in hot water for a while, then you can peel it off.2, use the hair dryer blow, the glue baking heat can be got down.3, with Fengyoujing rub, then try out.4, you can try a rubber. But in the beginning, you may think the more you rub the dirt, but the longer the rub, you will see the effect, this method is relatively tired, have perseverance.5, with blisters, put a little detergent, and then use an old toothbrush to brush.6, with a cloth with alcohol or Erguotou wipe it.

Send your message to us

NYLON CONVEYOR BELT-Plied textile conveyor belts

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords