Poly Tube Netting

Poly Tube Netting Related Searches

Protective Netting Plastic Wire Netting Plastic Safety Netting Clear Plastic Netting Rigid Plastic Netting Garden Plastic Netting Green Plastic Netting Flexible Netting Plastic Netting Nz Black Plastic Garden Netting Barrier Fence Netting Plastic Deer Netting Plastic Netting Uk Plastic Netting For Gardens Plastic Garden Netting Fencing Polypropylene Tape Garden Screen Netting Vexar Netting Plastic Garden Netting Uk Colored Polypropylene Tubing Plastic Tubing Dip Tubes Clear Packaging Tubes Rubber Tube Fittings Iron Tubes Package Sealing Tape Clear Plastic Shipping Tubes Media Packeting Shipping Tape Small Plastic TubesPoly Tube Netting Supplier & Manufacturer from China

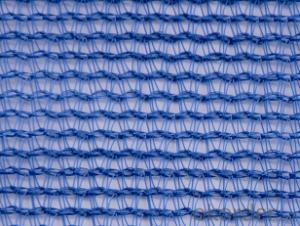

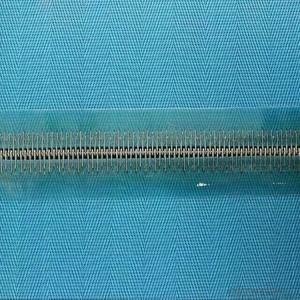

Poly Tube Netting is a versatile product that consists of a polyethylene tube with a netting woven around it. This unique combination of materials provides both strength and flexibility, making it suitable for a wide range of applications. The netting is designed to offer protection and support to various objects, while the poly tube ensures durability and resistance to environmental factors.Poly Tube Netting is widely used in various industries, including agriculture, construction, and sports. In agriculture, it is often employed for trellising and supporting plants, providing a sturdy structure for them to grow on. In construction, it can be used for reinforcing concrete structures or as a safety barrier. In sports, it is commonly seen as a protective barrier in areas such as baseball backstops and soccer goal enclosures. Its versatility and durability make it an ideal choice for these and many other applications.

Okorder.com is a leading wholesale supplier of Poly Tube Netting, boasting a large inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products they offer are of the highest standard. This makes them a reliable source for those seeking to purchase Poly Tube Netting for their specific requirements.

Hot Products