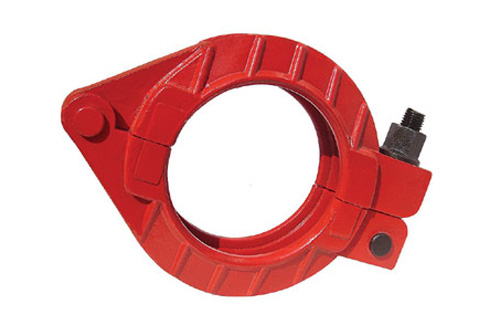

Pipeline Coupling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Size: 2"-8" (DN50-DN200)

Brand: Putzmeister, Schwing, Sany

Series: Screw Coupling, Bolt Coupling, SnapCoupling

Other products:

1) Putzmeister/ Schwing/ Zoomlion/ SermacRam Pistons

2) Putzmeister/ IHI/ Kyokuto/ Zoomlion/ SanySeperated Piston

3) Wear-resisting board and Cuts ink

4) Rubber hose

5) ST52 steel pipe, elbow, reducer

6) Cleaning seriesand others- Q: Are there any safety considerations when using concrete pump spare parts?

- Yes, there are several safety considerations that should be taken into account when using concrete pump spare parts. Firstly, it is important to ensure that the spare parts are of high quality and are compatible with the specific make and model of the concrete pump. Using substandard or incorrect spare parts can lead to equipment failure, which can be dangerous for the operator and those working in the vicinity. Additionally, proper maintenance and inspection of the spare parts is crucial for safety. Regularly inspecting the parts for any signs of wear or damage can help identify potential issues before they cause accidents or equipment failure. It is also important to follow the manufacturer's guidelines for maintenance and replacement intervals. When using concrete pump spare parts, it is essential to follow all safety procedures and protocols. This includes wearing appropriate personal protective equipment (PPE), such as safety goggles, gloves, and steel-toed boots. It is also important to ensure that all operators are trained in the proper use of the equipment and understand the potential hazards involved. Furthermore, it is crucial to follow safe operating practices when using concrete pump spare parts. This includes maintaining a safe distance from the working area, ensuring that the concrete pump is stable and secure, and avoiding overloading or exceeding the recommended operating capacity. By considering these safety considerations and following proper procedures, the risks associated with using concrete pump spare parts can be minimized, ensuring the safety of operators and those working on the construction site.

- Q: What is the difference between concrete pump and ground pump?

- The pump is easy to move and flexible, but generally limited to the length of the boom by 60-70m. The ground pump is not limited by height, but it needs to be connected with the conveying pipe, which is of poor flexibility

- Q: How often should a concrete pump spectacle plate be replaced?

- The frequency of replacing a concrete pump spectacle plate depends on various factors such as usage intensity, maintenance practices, and the condition of the plate. However, as a general guideline, it is recommended to inspect and potentially replace the spectacle plate every 500 to 1000 hours of operation or sooner if signs of wear or damage are observed. Regular inspections and timely replacements help ensure optimal performance and prevent any potential safety risks.

- Q: How long do concrete pump pipes typically last?

- Concrete pump pipes typically last between 25,000 to 40,000 cubic meters of concrete pumped. However, the lifespan of these pipes can vary based on several factors such as the quality of the pipes, the type of concrete being pumped, the pumping pressure, and the maintenance practices followed. Regular inspections, cleaning, and proper storage can help extend the lifespan of concrete pump pipes. Ultimately, it is essential to monitor the wear and tear of the pipes and replace them when necessary to ensure efficient and safe concrete pumping operations.

- Q: How do I identify the specific spare parts I need for my concrete pump?

- To identify the specific spare parts you need for your concrete pump, you can follow these steps: 1. Consult the user manual: Start by referring to the user manual provided by the manufacturer. It typically contains a detailed parts list along with part numbers and descriptions. The manual may also include diagrams or illustrations to help you identify the required spare parts. 2. Contact the manufacturer: Reach out to the manufacturer of your concrete pump. They will have the most accurate and up-to-date information about the spare parts for your specific model. Provide them with the model number and any other relevant details to ensure accurate identification of the required parts. 3. Engage with authorized dealers or distributors: If the manufacturer is unable to directly provide you with the spare parts, they can often refer you to authorized dealers or distributors. These professionals specialize in concrete pump parts and can help you identify the specific spare parts you need. Share the model number and any other relevant details to assist them in finding the correct parts. 4. Take pictures or measurements: If you are unable to find the required information through the manual, manufacturer, or authorized dealers, you can take pictures or measurements of the damaged or worn-out parts. This will help in visually identifying the parts and providing accurate dimensions, which can be shared with suppliers or experts in the field who may be able to assist you further. 5. Online research: Utilize online resources such as parts catalogs, forums, or websites dedicated to concrete pump spare parts. These platforms often have extensive databases and knowledgeable communities that can help you identify the specific spare parts you need. Search for your concrete pump model and explore the available resources to find the relevant parts. Remember to prioritize quality and authenticity while purchasing spare parts for your concrete pump. It is essential to buy from reputable sources to ensure the durability and longevity of your equipment.

- Q: Are there any specific guidelines for the storage and handling of concrete pump spare parts during transportation?

- Concrete pump spare parts must be stored and handled according to specific guidelines during transportation to ensure safety and efficiency, as well as minimize the risk of damage or loss. To begin, it is crucial to package and protect the spare parts properly. This entails using suitable materials like cardboard boxes, bubble wrap, or foam padding to prevent any physical harm during transit. The spare parts must be securely packed to prevent any movement or shifting during transportation. Furthermore, it is advisable to clearly label the packages with the contents and any specific handling instructions. This will aid transport personnel in correctly handling the spare parts and avoiding mishandling or confusion. Moreover, it is essential to select a trustworthy and experienced transportation service provider who specializes in delicate and sensitive items such as concrete pump spare parts. They should possess the necessary equipment, such as pallet jacks or forklifts, for safe handling and movement of the spare parts. During transportation, it is vital to ensure that the spare parts are loaded and secured properly in the transport vehicle. This may involve using straps, ropes, or other securing devices to prevent any movement or shifting of the packages. Regarding temperature control, it is important to consider the specific requirements of the spare parts. Some parts may be sensitive to extreme temperatures and necessitate special handling or climate-controlled transportation. Consulting with the manufacturer or supplier of the spare parts is crucial to determine any specific temperature or climate requirements. In conclusion, adhering to these guidelines will guarantee the secure and safe transportation of concrete pump spare parts, reducing the risk of damage or loss and ensuring their readiness for use upon arrival at their destination.

- Q: What do these types of concrete pumps mean?

- After the 16 is the motor power kW (landlord 16 seems to have a mistake, usually 110) or the manufacturer's serial number.

- Q: What is the purpose of a concrete pump hydraulic oil cooler?

- The primary function of a concrete pump hydraulic oil cooler is to keep the hydraulic oil in the system at the ideal temperature. The hydraulic oil powers the hydraulic system of the pump, which is responsible for operating different components like pistons, cylinders, and valves. While the pumping process is ongoing, the constant movement and pressure can cause the hydraulic oil to heat up. If the oil gets too hot, its viscosity decreases, which negatively impacts the overall efficiency and performance of the pump. Additionally, excessive heat can cause the hydraulic oil to deteriorate and break down, resulting in increased wear and tear on the pump's components. To prevent these problems, a concrete pump hydraulic oil cooler is utilized. It typically functions as a heat exchanger, transferring heat from the hydraulic oil to a cooling medium like air or water. This helps regulate the temperature of the hydraulic oil and keeps it within a safe operating range. By maintaining the optimal temperature, the hydraulic oil cooler guarantees that the hydraulic system functions efficiently and effectively. It also helps extend the pump's lifespan by reducing the risk of overheating and excessive component wear. Moreover, it preserves the quality of the hydraulic oil, allowing it to retain its lubricating properties and prevent any potential harm to the system. In conclusion, the goal of a concrete pump hydraulic oil cooler is to control the temperature of the hydraulic oil to optimize the performance, efficiency, and longevity of the pump's hydraulic system.

- Q: Can concrete pump spare parts be repaired on-site, or should they be sent to a specialized repair facility?

- Concrete pump spare parts can be repaired on-site, depending on the complexity of the repair and the expertise of the maintenance personnel. However, for more intricate or major repairs, it is recommended to send the spare parts to a specialized repair facility where they can be properly assessed, repaired, and tested by professionals to ensure optimal functionality and safety.

- Q: What is the function of a concrete pump hydraulic motor?

- The function of a concrete pump hydraulic motor is to provide the necessary power and force required to operate the concrete pump. The hydraulic motor is responsible for converting hydraulic energy into mechanical energy, which allows the pump to work efficiently and effectively. It drives the pumping mechanism, allowing the concrete to be pumped through the pipeline and delivered to the desired location. The hydraulic motor also controls the speed and direction of the pump, enabling precise placement of the concrete. Overall, the concrete pump hydraulic motor plays a crucial role in ensuring the smooth operation and successful delivery of concrete in construction projects.

Send your message to us

Pipeline Coupling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords