3M Seamless Delivery Pipe for Cifa Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

3M Seamless Delivery Pipe for Cifa Concrete Pump

1. Structure of 3M Seamless Delivery Pipe for Cifa Concrete Pump:

St52 Weld Pipe: Main use for Trailer-mounted pump, thickness has 4.0mm, 4.5mm, 5mm. Compare with for Truck-mounted pump. Weld pipe has cheaper price, so it is popular in Saudi, Pakistan, India, etc. Unit Price is about 30USD-33USD.

St52 Seamless Pipe: Now More People like use this kind for Truck Pump and Trailer Pump because of the quality is better and it is seamless kind, so this kind pipe is most popular in Middle East Price About 34USD-37USD.

Wear Resistant Pipe: Use for Truck Pump, Wear Resistant Layer is 2.5mm.Through heat treatment way make this pipe more strong (HRC60-62), Using Life: 25,000m³-35,000m³ Price about 65USD-68USD.

Two Wall Pipe: This pipe thickness (2mm+2.5mm), Using Life about 50,000m³-60,000m³

2. Main Features of 3M Seamless Delivery Pipe for Cifa Concrete Pump:

• High Wear-resistant, long service life, lower cost

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Ensure the supply of ancillary parts

• Our company passed the ISO9000 certification, the product through 3C certification in full compliance with national standards

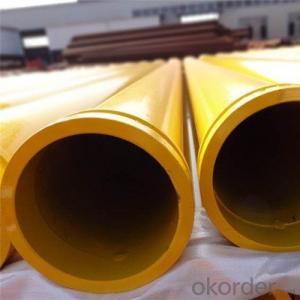

3. 3M Seamless Delivery Pipe for Cifa Concrete Pump Images

4. 3M Seamless Delivery Pipe for Cifa Concrete Pump Specification

Production Process

5. FAQ

We have organized several common questions for our clients, may help you sincerely:

①Is your products exported a lot?

We have exported to many, many countries. Every year we ship more than 30 containers of these spare parts. Our main market is in Middle-east, Asia & Africa.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 15 working days can be served.

6. Why choose us

• We are a comprehensive manufacturing and trading company.

• Our company is one of the biggest manufacturing and trading companies in China.

• We have been specialized in producing concrete pump spare parts and specialized in producing all kinds of concrete pump parts. As Concrete Pump Pipe, Concrete Pump Elbow, Concrete Pump Rubber Hose, Concrete Pump Wear Plate, Concrete Pump S Valve, Concrete Pump Piston and so on.

• We have been supplying concrete pump parts for SCHWING, PUTZMEISTER, SANY, CIFA, KYOKUTO, ZOOMLION for 10 years, so we can promise you the quality and best price.

- Q: How can one identify the correct type of rubber seals or gaskets for concrete pump spare parts?

- To identify the correct type of rubber seals or gaskets for concrete pump spare parts, one should consider several factors. Firstly, it is important to know the specific model and make of the concrete pump to ensure compatibility. Additionally, one should evaluate the application requirements, such as the pressure and temperature conditions the seals or gaskets will be exposed to. Considering the material compatibility with the fluids or chemicals being pumped is also crucial. Consulting the manufacturer's specifications or seeking expert advice can provide further guidance in identifying the correct type of rubber seals or gaskets for concrete pump spare parts.

- Q: Are there any specific guidelines for the selection and installation of hydraulic components in concrete pump spare parts?

- Yes, there are specific guidelines for the selection and installation of hydraulic components in concrete pump spare parts. When choosing hydraulic components for concrete pump spare parts, it is important to consider factors such as the maximum operating pressure, flow rate, and compatibility with the existing hydraulic system. Firstly, it is crucial to ensure that the selected hydraulic components can handle the maximum operating pressure of the concrete pump. This includes components such as hydraulic cylinders, valves, and pumps. Choosing components with a higher pressure rating than the concrete pump's operating pressure can help ensure their durability and longevity. Secondly, the flow rate of the hydraulic components should match the requirements of the concrete pump system. Components such as hydraulic pumps and valves must be able to provide sufficient flow to operate the concrete pump effectively. It is important to consider factors such as the size of the concrete pump, the desired output capacity, and the specific pumping requirements. Moreover, compatibility with the existing hydraulic system is crucial for the smooth operation of the concrete pump. Hydraulic components should be selected based on their compatibility with the existing system in terms of fittings, connections, and overall design. It is advisable to consult the manufacturer's guidelines or seek professional advice when selecting and installing hydraulic components in concrete pump spare parts. Furthermore, proper installation is essential to ensure the optimal performance and safety of hydraulic components in concrete pump spare parts. It is recommended to follow the manufacturer's installation instructions and guidelines. The installation process should include proper alignment, secure mounting, and appropriate sealing of the components to prevent any leaks or failures. In conclusion, there are specific guidelines for the selection and installation of hydraulic components in concrete pump spare parts. Considering factors such as maximum operating pressure, flow rate, compatibility, and following proper installation procedures can help ensure the efficient and safe operation of the concrete pump system.

- Q: How often should the concrete pump wear plate be replaced?

- The frequency of replacing the concrete pump wear plate depends on several factors such as the type of concrete being pumped, the volume of concrete being pumped, and the operating conditions of the pump. Generally, wear plates are designed to withstand a certain amount of wear and tear before requiring replacement. In most cases, it is recommended to inspect the wear plate regularly to check for signs of excessive wear. This can include visible cracks, erosion, or a significant decrease in thickness. Regular visual inspections can help determine when it is time to replace the wear plate. Additionally, monitoring the pump's performance and efficiency can also provide insights into the wear and tear on the wear plate. If there is noticeable decrease in the pump's output or an increase in the required pumping pressure, it may indicate that the wear plate needs to be replaced. However, it is important to consult the manufacturer's guidelines and recommendations for your specific concrete pump model. They often provide recommendations on the expected lifespan of the wear plate and the intervals at which it should be replaced. Following these guidelines can help ensure optimal performance and longevity of your concrete pump.

- Q: What are the types, classifications and specifications of concrete pump?

- According to the maximum hourly transport rate, there are 20-100m3 range, and most of the concrete pump can achieve two variable displacement or stepless variable

- Q: How can a malfunctioning hydraulic motor affect the pumping process?

- Various negative effects can occur in the pumping process due to a hydraulic motor malfunction. Firstly, there may be a decrease in pumping efficiency. The hydraulic motor is responsible for converting hydraulic energy into mechanical energy, which drives the pumping mechanism. If the motor is not functioning properly, it may not generate enough power to operate the pumping system effectively, resulting in a decrease in the volume or pressure of the pumped fluid. Moreover, an increase in energy consumption can be caused by a faulty hydraulic motor. Inefficient or faulty motor operation can lead to higher energy requirements to maintain the desired pumping rate. This increased energy consumption can result in higher operating costs and reduced overall system performance. Furthermore, irregular pumping or complete pump failure can occur as a result of a malfunctioning hydraulic motor. If the motor is not operating correctly, it may cause intermittent or inconsistent pumping, leading to fluctuations in the flow rate or pressure of the pumped fluid. In extreme cases, the motor may stop working entirely, resulting in a total loss of pumping functionality. Additionally, the entire pumping system may experience increased wear and tear due to a malfunctioning hydraulic motor. Improper motor operation can create excessive vibration or heat, leading to premature failure of other components such as seals, bearings, or pistons. This can result in frequent maintenance or repair requirements, leading to increased downtime and costs. In summary, the pumping process can be significantly affected by a malfunctioning hydraulic motor. This includes decreased efficiency, increased energy consumption, irregular pumping or complete pump failure, and increased wear and tear on the system. It is essential to regularly inspect and maintain hydraulic motors to ensure proper functioning and avoid potential issues that may disrupt the pumping process.

- Q: How can the concrete pump be installed and used?

- Operation should be carried out before the examination, to confirm the normal electrical equipment and instrumentation, each part of the switch button, the handle in the correct position, the mechanical part of the fastening point is firm and reliable, and the chain belt tightness to meet the requirements, the normal operation of the transmission parts

- Q: What are some common issues with concrete pump pipes and how can they be prevented?

- Some common issues with concrete pump pipes include clogging, wear and tear, and leakage. These issues can be prevented by regularly cleaning the pipes to avoid clogging, using high-quality pipes that are resistant to wear and tear, and ensuring proper installation and maintenance to prevent leakage. Additionally, using the correct concrete mix and adjusting the pump pressure appropriately can also help prevent these issues.

- Q: What are the different types of concrete pump hopper agitator motors?

- There are generally two types of concrete pump hopper agitator motors: electric motors and hydraulic motors. Electric motors are powered by electricity and are commonly used in smaller and portable concrete pumps. Hydraulic motors, on the other hand, are driven by hydraulic power generated by the concrete pump itself and are typically used in larger and stationary concrete pumps.

- Q: How often should concrete pump water pumps be inspected and replaced?

- Concrete pump water pumps should be inspected regularly, ideally on a monthly basis, to ensure they are functioning properly and to catch any potential issues early on. However, the frequency of replacement will depend on various factors such as the pump's usage, maintenance, and overall condition. It is recommended to consult the manufacturer's guidelines and seek professional advice for determining the specific replacement schedule for concrete pump water pumps.

- Q: What are the indications of an inaccurate concrete pump pressure gauge?

- There are several indications that can suggest an inaccurate concrete pump pressure gauge. Here are a few: 1. Inconsistent readings: If the pressure gauge consistently gives varying readings even when the concrete pumping conditions remain constant, it could be a sign of an inaccurate gauge. For example, if the gauge displays a pressure of 1000 psi one moment and then jumps to 1500 psi without any significant changes in the pumping operation, it could indicate an issue with the gauge. 2. Unusual or abnormal readings: If the pressure gauge consistently displays extremely high or low pressure readings that are significantly different from the expected values, it could signify an inaccurate gauge. It is important to be aware of the typical pressure range for the specific concrete pumping operation to identify abnormal readings. 3. Incongruity with other gauges: If there are multiple pressure gauges installed in the concrete pumping system, and they provide significantly different readings, it could suggest that one or more of the gauges are inaccurate. Comparing the readings of various gauges can help determine if a particular gauge is faulty. 4. Inadequate pump performance: If the concrete pump is not performing as expected, such as experiencing reduced output or inconsistent flow rates, it could be due to inaccurate pressure readings. Inaccurate pressure measurements can affect the control of the pump's hydraulic system, leading to inefficiencies in pumping operations. 5. Physical damage or wear: Any visible damage or signs of wear on the pressure gauge, such as cracked glass, bent needles, or loose connections, can compromise its accuracy. Such physical damage can lead to inaccurate readings and should be addressed promptly. It is important to regularly calibrate and maintain the pressure gauge to ensure accurate readings. If any indications of an inaccurate gauge are observed, it is recommended to consult a professional technician or engineer to assess the situation and take appropriate actions to rectify the issue.

Send your message to us

3M Seamless Delivery Pipe for Cifa Concrete Pump

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords