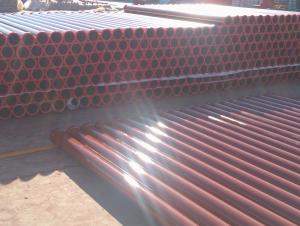

CONCRETE DELIVERY PIPE ST 52 WITH 148 FLANGE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Materials: ST 52

Concrete Pumping Capacity: about20, 000M3

Inner Diameter: 125mm

Outer Diameter: 133mm

Thickness: 4.5mm

Length: 3000mm

Notes: total series of concrete delivery pipe for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc)available.

Scope of Application of the Equipment

Concrete Delivery Pipe widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc. Our concrete delivery pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber piston, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

Product Advantages:

Concrete Delivery Pipe are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Product Specifications:

Dimensions and masses of the complete pipe and its major components

FAQ:

Q1: Why buy Materials & Equipment from us?

A1: All products have their ISO certifications, and adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Delivery Pipe according to customers request?

A4: Yes, we can produce Concrete Delivery Pipe according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: Where can I buy concrete pump spare parts?

- There are several places where you can buy concrete pump spare parts. One option is to check with the manufacturer of your concrete pump. They usually have authorized dealers or distributors that sell genuine spare parts for their equipment. This ensures the quality and compatibility of the parts with your specific pump model. Another option is to look for specialized construction equipment suppliers or dealers in your area. These companies often carry a wide range of spare parts for various types and brands of concrete pumps. You can visit their physical stores or check their websites to see if they have the specific parts you need. Online marketplaces and platforms are also a convenient option for purchasing concrete pump spare parts. Websites like Amazon, eBay, and Alibaba have a vast selection of spare parts from different sellers worldwide. You can compare prices, read reviews, and choose the parts that best suit your needs. Before making a purchase, it is essential to ensure that you are buying from a reputable source. Look for sellers with positive feedback or ratings, and check if they offer warranties or return policies. Additionally, consider factors like shipping costs, delivery times, and customer service when deciding where to buy your concrete pump spare parts.

- Q: Can I get spare parts for both concrete pumps with and without boom stabilizers?

- Yes, spare parts are available for both concrete pumps with and without boom stabilizers. When it comes to concrete pumps, manufacturers typically offer a wide range of spare parts to ensure the longevity and smooth operation of their equipment. These spare parts can include hydraulic components, valves, hoses, seals, wear plates, pipes, and many others. Whether your concrete pump has a boom stabilizer or not, you can easily find and purchase spare parts from the manufacturer or authorized dealers. Additionally, there are also aftermarket suppliers who specialize in providing spare parts for various concrete pump models. So, regardless of the specific features of your concrete pump, you can rest assured that spare parts are readily available to keep your equipment running smoothly.

- Q: What is the role of a concrete pump agitator shaft seal?

- The role of a concrete pump agitator shaft seal is to prevent leakage of concrete slurry or other fluids from the agitator shaft, ensuring that the pump operates efficiently and without any loss or contamination of the material being pumped.

- Q: How to operate the concrete pump?

- The size of sand and gravel, cement mark and mixture ratio should meet the requirement of the mechanical performance of the pump according to the specifications of the factory

- Q: What are the indications of a worn-out concrete pump clamp?

- A worn-out concrete pump clamp may exhibit several indications that replacement is necessary. These indications commonly include: 1. Leakage: In the event of leakage around the clamp area while operating the concrete pump, it could signify a worn-out clamp. This leakage may be a result of a faulty seal or gasket, which can no longer establish a secure and tight connection between the pump and the hose. 2. Vibrations and rattling: Excessive vibrations and rattling during the pumping process can be attributed to a worn-out clamp. This can occur when the clamp fails to firmly hold the hose in place, resulting in movement and instability. 3. Difficulty in tightening: If you encounter increasing difficulty in properly tightening the clamp, it may indicate wear-out. Over time, the components of the clamp may deteriorate, making it more challenging to achieve a secure and tight connection. 4. Visual damage: Inspect the clamp for visible signs of damage, such as cracks, dents, or corrosion. These physical damages can compromise the clamp's functionality, potentially leading to leaks or instability. 5. Excessive wear and tear: If you have been utilizing the same concrete pump clamp for an extended period without replacement, it is advisable to regularly inspect it for signs of excessive wear and tear. This may include worn-out or missing bolts, a deformed clamp body, or any other visible signs of deterioration. Promptly addressing any indications of a worn-out concrete pump clamp is crucial to ensure the safety and efficiency of pumping operations. If any of these signs are observed, it is recommended to seek professional consultation or replace the clamp to prevent potential accidents or disruptions in the concrete pumping process.

- Q: Are there any specific guidelines for the storage and handling of concrete pump spare parts during transportation?

- Yes, there are specific guidelines for the storage and handling of concrete pump spare parts during transportation. These guidelines include ensuring proper packaging and labeling of the spare parts, using appropriate containers or packaging materials to protect them from damage, securely fastening and securing the spare parts to prevent movement during transit, and following any specific instructions provided by the manufacturer for handling and storing the spare parts. It is also important to consider factors such as temperature, humidity, and potential hazards during transportation to ensure the integrity and quality of the spare parts.

- Q: Are there any specific safety precautions while replacing concrete pump spare parts?

- There exists a variety of safety precautions that must be followed when replacing concrete pump spare parts. 1. Personal Protective Equipment (PPE) is of utmost importance and should be worn to safeguard against potential hazards. This includes safety goggles, gloves, a helmet, and steel-toed boots. 2. It is essential to adhere to proper lockout/tagout procedures prior to replacing any spare parts. This entails disconnecting and securing the power source to prevent accidental startup of the pump. 3. Before commencing the replacement process, inspect all tools and equipment for any indications of damage or defects. It is crucial to refrain from using faulty equipment, as it can pose significant safety risks. 4. When handling heavy spare parts, it is imperative to employ appropriate lifting techniques to prevent strain or injury. Ensure that proper assistance and equipment, such as cranes or forklifts, are available if necessary. 5. Maintain a clean and well-organized work area to prevent trips, slips, and falls. Remove any obstacles or debris that may jeopardize safety during the replacement process. 6. Only trained and authorized personnel should be involved in the replacement of concrete pump spare parts. They must possess a thorough understanding of the equipment and procedures to minimize the likelihood of accidents. 7. Always consult the manufacturer's guidelines and instructions when replacing spare parts. This will ensure that the process is executed safely and accurately. 8. It is vital to have a plan in place for potential emergencies, including fires or injuries. Make certain that fire extinguishers and first aid kits are easily accessible, and that all workers are familiar with their locations and usage. By adhering to these safety precautions, the risk of accidents, injuries, and damage can be significantly reduced when replacing concrete pump spare parts.

- Q: What are the advantages of using stainless steel components in concrete pump spare parts?

- There are several advantages of using stainless steel components in concrete pump spare parts. Firstly, stainless steel has excellent corrosion resistance, which ensures the longevity and durability of the spare parts even in harsh environments. Secondly, stainless steel is known for its high strength-to-weight ratio, providing increased strength and reliability without adding excessive weight to the concrete pump. Additionally, stainless steel is highly resistant to wear and tear, which reduces the need for frequent replacements and maintenance. Lastly, stainless steel components offer a hygienic and clean surface, making them suitable for applications in the construction industry where cleanliness is crucial.

- Q: What are the common signs of wear and tear in a concrete pump cylinder?

- Some common indications that a concrete pump cylinder is experiencing wear and tear include: 1. Leakage of oil or hydraulic fluid: The presence of oil or hydraulic fluid leaking from the cylinder is a clear indication that it has sustained damage or wear. This could be a result of cracks, worn seals, or damaged gaskets. 2. Decreased pumping efficiency: A worn cylinder may lead to a reduction in pumping efficiency, resulting in the concrete pump's inability to deliver the same amount of concrete as before. This decline could be due to a decrease in the cylinder's internal diameter or worn piston rings. 3. Heightened noise and vibration: As the cylinder deteriorates, it may produce more noise and vibration during operation. This can suggest issues like misalignment, loose components, or damaged internal parts. 4. Uneven or rough concrete output: A worn cylinder can cause the concrete output to be uneven or rough. This issue may arise from an irregular internal surface or damaged piston rings, which disrupt the smooth movement of the piston. 5. Excessive generation of heat: A worn concrete pump cylinder may generate additional heat while in operation. This can be attributed to increased friction between moving parts, which can further contribute to accelerated wear and tear. 6. Visible damage or corrosion: By inspecting the cylinder's surface, visible signs of wear and tear such as scratches, dents, or corrosion can be identified. These damages can compromise the cylinder's integrity and may necessitate repair or replacement. It is crucial to regularly inspect the concrete pump cylinder and promptly address any signs of wear and tear to prevent further damage and maintain the pump's optimal performance.

- Q: What are the indications of an inaccurate concrete pump pressure gauge?

- Some indications of an inaccurate concrete pump pressure gauge may include inconsistent readings, sudden drops or spikes in pressure, or when the gauge fails to return to zero when the pump is turned off.

Send your message to us

CONCRETE DELIVERY PIPE ST 52 WITH 148 FLANGE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords