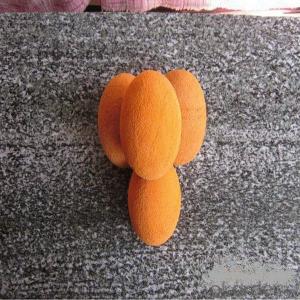

Concrete pump sponge ball DN100 for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name: CONCRETE PUMP CLEANING SPONGE BALL

1. Specification

Name | Material | Size | Function |

Clean Ball | Sponge Rubber | DN 80(3inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 100(4inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 125(5inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 150(6inch) | Clean pump pipe |

Clean Ball | Sponge Rubber | DN 200(8inch) | Clean pump pipe |

2. Application

1.Applacation:cleaning the pipeline of the concrete pump

2.Suitable for the various :Schwing CIFA PMZoomlion SANY and so on.

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Concrete Pump Cleaning Sponge Ball with Good Quality according to customers request?

A4: Yes, we can produce Concrete Pump Cleaning Sponge Ball according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image:

- Q: Are there any specific maintenance requirements for concrete pump spare parts?

- Yes, there are specific maintenance requirements for concrete pump spare parts. Regular inspections, cleaning, and lubrication are essential to ensure the optimal performance and longevity of the parts. Additionally, proper storage, handling, and timely replacement of worn-out components are crucial to maintain the efficiency and safety of the concrete pump.

- Q: Can I get spare parts for both concrete pumps with and without pressure washers?

- Yes, spare parts are available for both concrete pumps with and without pressure washers.

- Q: How often should I replace concrete pump spare parts?

- The frequency at which you should replace concrete pump spare parts depends on various factors such as the quality of the parts, the intensity of usage, and regular maintenance. Generally, it is recommended to conduct regular inspections and maintenance to identify any signs of wear or damage in the spare parts. As a preventive measure, it is advisable to replace parts that show significant wear or are no longer functioning optimally. However, it is crucial to follow the manufacturer's guidelines and recommendations for the specific concrete pump model you are using. Additionally, consulting with experienced professionals or technicians in the field can provide valuable insights on the expected lifespan of different spare parts and when replacements may be necessary.

- Q: Can I get spare parts for both concrete pumps with and without boom control systems?

- Yes, you can typically get spare parts for both concrete pumps with and without boom control systems. Many manufacturers and suppliers of concrete pumps offer a wide range of spare parts to meet the needs of different types of pumps. Whether it's for a pump with a boom control system or one without, you should be able to find the necessary spare parts from reputable suppliers. It is recommended to contact the manufacturer or supplier directly to inquire about the availability and compatibility of spare parts for your specific concrete pump model.

- Q: How can one determine the correct size and dimensions of concrete pump spare parts?

- To determine the correct size and dimensions of concrete pump spare parts, there are several important steps to follow: 1. Identify the specific make and model of your concrete pump: Each concrete pump has its own unique specifications and requirements for spare parts. Therefore, it is crucial to know the make and model of your pump before ordering any spare parts. 2. Consult the manufacturer's documentation: Manufacturers often provide detailed documentation that includes information on the required size and dimensions of spare parts. This documentation may include technical drawings, diagrams, and part numbers that can help you find the correct size. 3. Measure the existing spare part: If you already have a spare part that needs replacement, you can measure its size and dimensions using precision tools like calipers or a measuring tape. Take accurate measurements of key dimensions such as length, width, height, and any other relevant specifications. 4. Seek professional assistance: If you are unsure about the correct size and dimensions, it is advisable to consult with a professional or an authorized dealer. They have expertise in concrete pumps and can guide you in selecting the right spare parts based on your pump's specifications. 5. Consider compatibility and quality: When purchasing spare parts, ensure they are compatible with your concrete pump's make and model. Additionally, prioritize quality to ensure longevity and optimal performance. Buying from reputable suppliers or directly from the manufacturer can help ensure the spare parts meet the necessary size, dimensions, and quality standards. By following these steps, you can accurately determine the correct size and dimensions of concrete pump spare parts, ensuring smooth operation and minimizing downtime.

- Q: How do I troubleshoot issues related to concrete pump spare parts control systems?

- To troubleshoot issues related to concrete pump spare parts control systems, it is important to follow a systematic approach. Here are some steps you can take: 1. Identify the problem: Begin by clearly identifying the issue you are experiencing with the control system. Is it not working at all? Are there specific functions or components that are not functioning correctly? Understanding the problem will help guide your troubleshooting efforts. 2. Check power supply: Ensure that the control system is receiving proper power supply. Check the power source, circuit breakers, and fuses to ensure there are no interruptions or faults in the electrical supply. If needed, replace or repair any faulty components. 3. Inspect connections: Examine the wiring connections and terminals within the control system. Loose or damaged connections can cause issues with the functioning of the system. Tighten any loose connections and repair or replace any damaged wiring. 4. Review control settings: Verify that the control settings are correctly adjusted according to the manufacturer's specifications. Incorrect settings can lead to malfunctions or inefficient operation. Consult the user manual or contact the manufacturer for guidance on proper control settings. 5. Perform diagnostic tests: Many control systems have built-in diagnostic features or error codes that can help identify specific issues. Consult the system's manual to understand how to access and interpret these diagnostic tools. Run any recommended diagnostic tests to pinpoint the problem area. 6. Inspect sensors and actuators: Sensors and actuators play a crucial role in the control system's operation. Check these components for any damage, misalignment, or malfunctioning. Clean or replace sensors as needed and ensure the actuators are properly connected and functioning correctly. 7. Consult technical support: If you have followed the above steps and are still unable to resolve the issue, it may be helpful to contact the manufacturer's technical support team. They can provide expert guidance on troubleshooting the specific control system and may suggest additional steps or solutions. Remember to always prioritize safety when troubleshooting control systems. Ensure that the pump is turned off and disconnected from the power source before working on any electrical components. If you are unsure or uncomfortable with any troubleshooting steps, it is best to seek professional assistance.

- Q: What is the function of a concrete pump hopper grate handle?

- The main purpose of a handle on a concrete pump hopper grate is to manually control the opening and closing of the grate. The grate is an essential part of the pump as it allows concrete to enter the pumping system. By using the handle, the operator can adjust the position of the grate in order to control the flow of concrete and prevent any large debris or foreign objects from entering the system. This is crucial for ensuring the smooth operation of the pump and maintaining the quality of the pumped concrete. Additionally, the handle provides easy access to the grate for maintenance and cleaning purposes. Overall, the handle on the concrete pump hopper grate plays a crucial role in regulating the flow of concrete and ensuring the efficiency and reliability of the pumping process.

- Q: How can one determine the correct voltage and current rating for electrical components in concrete pump spare parts?

- Several factors must be considered when determining the appropriate voltage and current rating for electrical components in concrete pump spare parts. The first step is to consult the manufacturer's specifications and documentation for both the concrete pump and its spare parts. These documents typically provide detailed information on the voltage and current requirements for each electrical component. It is important to closely follow these guidelines to ensure that the components are operated within their intended parameters. Next, it is crucial to have a thorough understanding of the electrical system and its requirements. This involves analyzing the power supply available at the site where the concrete pump will be used. Factors such as the voltage level (e.g., 110V, 220V, 440V) and frequency (e.g., 50Hz, 60Hz) of the electrical supply must be taken into account. Additionally, the maximum current capacity of the electrical system should be considered to avoid overloading. Furthermore, it is advisable to assess the specific application and operating conditions of the concrete pump. Different components may have varying voltage and current requirements depending on their function and the environment in which they are used. For example, components installed outdoors may require higher voltage ratings to withstand harsh weather conditions. Lastly, seeking assistance from qualified electricians or engineers is highly recommended. They have the expertise and knowledge to accurately determine the voltage and current ratings for electrical components in concrete pump spare parts. Their experience allows them to consider various factors, including safety regulations, compatibility with the existing electrical system, and any specific requirements from the concrete pump manufacturer. By considering the manufacturer's specifications, understanding the electrical system, evaluating the application and operating conditions, and seeking professional advice, one can effectively determine the appropriate voltage and current rating for electrical components in concrete pump spare parts.

- Q: Are there any specific quality control measures for the production of concrete pump spare parts?

- Yes, there are specific quality control measures for the production of concrete pump spare parts. These measures are put in place to ensure that the spare parts meet the required specifications and are of high quality. One of the key quality control measures is the use of standardized production processes. Manufacturers follow specific procedures and guidelines to produce the spare parts, ensuring consistency and accuracy in the manufacturing process. This includes using quality materials, following precise measurements, and employing advanced manufacturing techniques. Quality control also involves rigorous testing and inspection of the spare parts throughout the production process. This includes conducting dimensional checks, hardness tests, and material composition analysis, among others. These tests help identify any defects or deviations from the required standards, allowing for timely corrective actions. Additionally, manufacturers may implement quality management systems, such as ISO 9001, to ensure continuous improvement in their production processes. These systems help establish quality objectives, monitor performance, and implement corrective actions when necessary. Furthermore, manufacturers may engage in third-party quality assessment and certification programs. This involves independent organizations conducting audits and inspections to ensure that the spare parts meet the required quality standards. Certifications from these programs provide assurance to customers about the quality and reliability of the spare parts. Overall, the production of concrete pump spare parts undergoes stringent quality control measures to ensure that they meet the necessary specifications and are of high quality. These measures help maintain the performance and durability of the spare parts, ensuring their reliability in concrete pump applications.

- Q: How can one determine the correct weight and balance requirements for concrete pump spare parts?

- To ascertain the appropriate weight and balance specifications for concrete pump spare parts, several factors must be taken into account. First and foremost, consulting the manufacturer's specifications and guidelines specific to the concrete pump model is of utmost importance. These documents typically contain comprehensive information regarding the weight and balance requirements for each spare part. Secondly, it is essential to comprehend the function and purpose of each spare part. Different components vary in weight and can significantly impact the overall balance of the pump. For example, larger elements like booms or outriggers may necessitate precise weight distribution to ensure operational stability. Moreover, considering the intended usage and environmental conditions of the concrete pump is imperative. If the pump is expected to operate in challenging terrains or extreme weather, additional weight might be necessary to enhance stability. In addition to the manufacturer's guidelines, seeking counsel from experts or engineers knowledgeable about concrete pumps can provide invaluable insights. These professionals can analyze the specific requirements of the pump and offer guidance on the appropriate weight and balance specifications for the spare parts. Lastly, conducting thorough testing and inspections after installing any spare parts is crucial. This ensures compliance with the weight and balance requirements and allows for any necessary adjustments to be made. In conclusion, determining the correct weight and balance requirements for concrete pump spare parts necessitates a combination of understanding manufacturer guidelines, considering the purpose and conditions of the pump, seeking expert advice, and performing comprehensive testing and inspections.

Send your message to us

Concrete pump sponge ball DN100 for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords