Concrete Pump ELBOW R275, 45DGR Grey with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

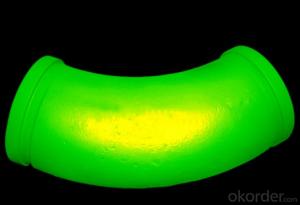

Product Name: Concrete Pump ELBOW R275, 45DGR DN125MM Grey with High Quality

1. Specification

Dimensions: DN100MM

Radius: 275mm,1000mm

Flange: SK, ZX, F&M

Degree: 30°, 45°, 90°

Material: #20 steel, ST52, Mn 13-4

Thickness: 4.5mm,6mm,7.1mm,7.5mm,10mm,

Working pressure: 180MPa

Notes: total series of concrete pump clamp for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

2. Application of Concrete Pump Bend DN125

Concrete Pump ELBOW R275, 45DGR DN125MM Grey widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery of Concrete Pump Bends

Every 60pcs Concrete Pump ELBOW R275, 45DGR DN125MM Grey put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump ELBOW R275, 45DGR DN125MM Grey according to customers request?

A4: Yes, we can produce Concrete Pump ELBOW R275, 45DGR DN125MM Grey according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: How can a faulty hydraulic filter affect the pump's hydraulic system?

- A faulty hydraulic filter can negatively impact the pump's hydraulic system in several ways. Firstly, it can allow contaminants such as dirt, debris, or particles to enter the hydraulic fluid, causing damage to the pump and other components. These contaminants can also clog or block the filter, reducing its efficiency and restricting the flow of fluid. This can lead to increased pressure, decreased performance, and potential overheating of the hydraulic system. Additionally, a faulty filter may fail to remove water or other contaminants from the fluid, further compromising the system's performance and reliability. Overall, a faulty hydraulic filter can result in reduced efficiency, increased wear and tear, and ultimately, system failure if not addressed promptly.

- Q: What are the different types of concrete pump hopper cylinders seals?

- There are several different types of concrete pump hopper cylinder seals, each designed to meet specific needs and requirements. Some of the most common types include: 1. Piston seals: These seals are designed to prevent leakage between the piston and cylinder bore. They are typically made of durable materials such as rubber or polyurethane, and are resistant to abrasion and wear. 2. Rod seals: Rod seals are installed on the piston rod to prevent leakage between the rod and cylinder head. They are often made of materials such as rubber or fabric-reinforced rubber, and provide reliable sealing even under high pressure conditions. 3. Wiper seals: Wiper seals are used to remove dirt, dust, and other contaminants from the piston rod as it retracts into the cylinder. They are typically made of polyurethane or rubber, and are designed to provide effective sealing and protection for the cylinder. 4. Wear rings: Wear rings are used to reduce friction and prevent metal-to-metal contact between the piston and cylinder bore. They are typically made of materials such as bronze or Teflon, and help to extend the lifespan of the cylinder by reducing wear and tear. 5. Backup rings: Backup rings are used in conjunction with other seals to provide additional support and stability. They are typically made of materials such as rubber or PTFE, and help to prevent extrusion and damage to the primary seal. Overall, the selection of the appropriate concrete pump hopper cylinder seal depends on factors such as the specific application, operating conditions, and desired performance characteristics. It is important to choose seals that are compatible with the pumped material, provide effective sealing, and have a long lifespan in order to ensure optimal performance and minimize maintenance requirements.

- Q: How often should I replace concrete pump spare parts?

- The frequency of replacing concrete pump spare parts depends on several factors such as the quality of the parts, the intensity of usage, and the maintenance practices. However, as a general guideline, it is recommended to inspect and replace worn or damaged concrete pump spare parts on a regular basis, typically every 6 to 12 months, to ensure optimal performance and avoid potential breakdowns or safety hazards.

- Q: How do I properly maintain and replace filters in concrete pump spare parts?

- To ensure optimal performance and longevity of your equipment, it is crucial to properly maintain and replace filters in concrete pump spare parts. Here are some guidelines to follow: 1. Get familiar with the different types of filters: Concrete pumps have various filters for hydraulic oil, fuel, air, and water. Take the time to understand which filters are used in your equipment. 2. Consult the manufacturer's instructions: Read the equipment manual and adhere to the guidelines provided by the manufacturer regarding filter maintenance and replacement intervals. This will ensure that you are following the recommended practices. 3. Conduct regular filter inspections: Periodically check the filters for signs of damage, clogging, or excessive debris accumulation. You can visually inspect them or measure the pressure differential across the filter. If the pressure differential exceeds the recommended limit, it may be necessary to replace the filter. 4. Clean or replace filters as required: If the filters are clogged or dirty, they should be cleaned or replaced. Some filters can be cleaned by blowing compressed air in the opposite direction of the airflow to remove debris. However, it is important to note that certain filters are disposable and cannot be cleaned. 5. Use authentic spare parts: When replacing filters, always opt for genuine spare parts recommended by the manufacturer. This ensures compatibility and performance. 6. Follow proper handling and installation procedures: When installing new filters, make sure to handle them with clean hands or wear gloves to prevent contamination. Follow the correct installation procedure, such as tightening the filter housing to the recommended torque value. 7. Maintain a regular maintenance schedule: Establish a consistent schedule for filter inspection, cleaning, and replacement. This will help you stay on top of filter maintenance and prevent potential issues caused by dirty or clogged filters. By adhering to these steps, you can effectively maintain and replace filters in concrete pump spare parts, ensuring efficient equipment operation and an extended lifespan.

- Q: How often should hopper grate springs be inspected or replaced in a concrete pump?

- Hopper grate springs in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure their proper functioning. However, the actual replacement of these springs depends on various factors such as the usage intensity, wear and tear, and manufacturer's recommendations. It is essential to monitor their condition closely and replace them promptly if any signs of damage or fatigue are observed.

- Q: What are some common issues with concrete pump pipes and how can they be prevented?

- Some common issues with concrete pump pipes include blockages, leaks, and wear and tear. These issues can be prevented by following proper maintenance and operational practices. 1. Blockages: Blockages occur when concrete hardens inside the pipe, hindering the flow. To prevent blockages, it is important to regularly clean the pipes after each use. Flushing the pipes with water or using a high-pressure air hose can remove any residual material and prevent build-up. Additionally, using concrete mixtures with proper consistency and avoiding excessive use of additives can reduce the likelihood of blockages. 2. Leaks: Leaks can occur due to cracks or gaps in the pipe, causing concrete to seep out. Regular inspection of the pipes is crucial to identify any signs of damage or wear. Repairing or replacing damaged sections promptly can prevent leaks. It is also essential to use high-quality pipes that are resistant to abrasion and chemical corrosion, as they are less prone to developing leaks. 3. Wear and Tear: Concrete pump pipes are subjected to significant stress and abrasion during operation. Over time, this can lead to wear and tear, resulting in weakened pipes or even breakages. To prevent excessive wear, it is important to use pipes made from durable materials such as hardened steel or composite materials. Regularly inspecting the pipes for signs of wear, such as thinning or deformation, and replacing them as needed can help prevent sudden failures. 4. Pipe movement and alignment issues: Concrete pump pipes can shift or become misaligned during operation, leading to reduced efficiency and potential damage. To prevent this, ensure that the pipes are securely fastened to the pump and properly aligned. Using clamps and brackets or employing anti-vibration measures can help maintain the stability and alignment of the pipes during pumping operations. 5. Operator errors: Improper handling and operation can also contribute to issues with concrete pump pipes. Operators should be adequately trained in operating the pump and handling the pipes. Following recommended operating procedures, avoiding excessive pressure or flow rates, and being cautious while maneuvering the pipes can prevent unnecessary strain and damage to the pipes. Overall, proactive maintenance, proper handling, and selecting high-quality pipes can significantly reduce common issues with concrete pump pipes, ensuring smooth and efficient concrete pumping operations.

- Q: How long does it take to receive concrete pump spare parts after placing an order?

- The time it takes to receive concrete pump spare parts after placing an order can vary depending on various factors such as the availability of the parts, shipping methods, and the location of the supplier. However, it typically takes anywhere from a few days to a couple of weeks for the parts to be delivered. It is always advisable to check with the supplier or manufacturer for a more accurate estimate based on your specific order.

- Q: Are there any specific guidelines for the storage and handling of concrete pump spare parts during transportation?

- Yes, there are specific guidelines for the storage and handling of concrete pump spare parts during transportation. These guidelines include ensuring proper packaging and labeling of the spare parts, using appropriate containers or packaging materials to protect them from damage, securely fastening and securing the spare parts to prevent movement during transit, and following any specific instructions provided by the manufacturer for handling and storing the spare parts. It is also important to consider factors such as temperature, humidity, and potential hazards during transportation to ensure the integrity and quality of the spare parts.

- Q: What is the function of a concrete pump control box?

- The concrete pump control box is a vital component of a concrete pump system, responsible for managing and controlling the operation of the pump to ensure a safe and efficient pumping process. By utilizing the control box, the operator can initiate, halt, and adjust the pumping speed of the concrete pump. Equipped with various control switches, knobs, and buttons, the control box facilitates control over different aspects of the pumping process. One of the key roles of the control box is to monitor the pressure and flow of the pumped concrete. This data is essential in guaranteeing that the concrete is pumped at the desired rate and consistency. Furthermore, the control box promptly notifies the operator of any irregularities or problems in the pumping system, such as clogs or blockages. Moreover, the control box may incorporate features like emergency stop buttons and safety interlocks to ensure the safety of both the operator and the equipment. Indicators and alarms may also be included to provide visual and audible cues regarding the pump's status and any potential issues that may arise. To summarize, the concrete pump control box's purpose is to equip the operator with the necessary controls and information to operate the concrete pump safely and efficiently. It ensures appropriate monitoring, control, and safety of the pumping process, ultimately leading to successful concrete placement.

- Q: How is the piping of the concrete pipe designed?

- Concrete conveying pipe is fixed, not directly supported on the reinforcing steel bar, and embedded parts, horizontal pipe should be fixed with a certain distance bracket, pad, sling etc, to facilitate the removal of plugging, dismantling and cleaning pipeline; vertical tube should be fixed on the wall or floor slab and column top hole with embedded parts

Send your message to us

Concrete Pump ELBOW R275, 45DGR Grey with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords