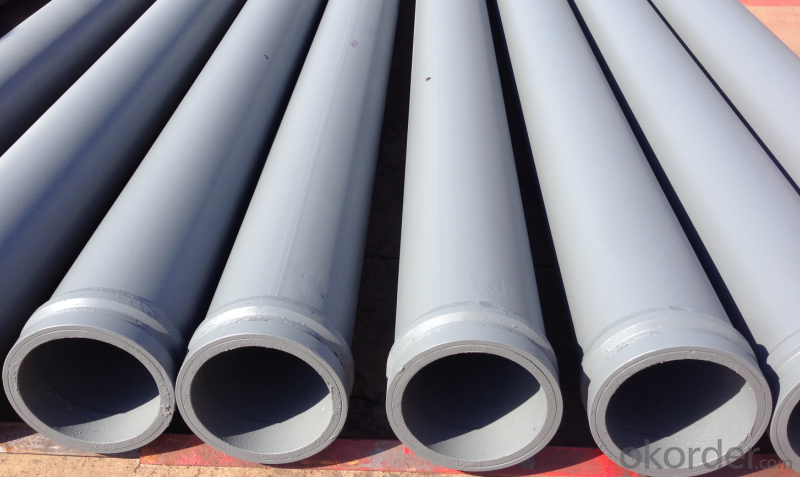

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. The inner side of this concrete pump pipe can undergoes heat treatment, and then the hardness can reach 63HRC.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 3m

Thickness: 4.1mm

Material: ST52

Weight: 40kg

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q:Are there any specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts. 1. Size and Compatibility: Ensure that the hydraulic filter or strainer you are installing is the correct size and compatible with the specific make and model of the concrete pump. Using the wrong size or incompatible filter can result in poor filtration or damage to the hydraulic system. 2. Location: The filter or strainer should be installed in a location that allows for easy access and maintenance. It should be positioned in a way that allows for proper filtration of the hydraulic fluid without obstructing the flow. 3. Mounting: The filter or strainer should be securely mounted to prevent any movement or vibration during operation. It is important to follow the manufacturer's instructions for proper mounting techniques and torque specifications. 4. Orientation: Pay attention to the recommended orientation of the filter or strainer. Some filters have specific flow direction requirements, and installing them incorrectly can affect their performance and efficiency. 5. Protection: Consider installing additional protection, such as a guard or shield, to prevent damage to the filter or strainer from external factors like debris or impacts. This can help prolong the lifespan and effectiveness of the filter. 6. Maintenance: Regularly inspect and clean the filter or strainer to ensure proper functioning. Follow the manufacturer's recommended maintenance schedule and procedures for replacement or cleaning to maintain optimal filtration efficiency. It is important to consult the manufacturer's instructions and guidelines for the specific hydraulic filter or strainer being installed, as they may have specific recommendations or requirements unique to their product.

- Q:What are the different types of concrete pump hopper agitator motors?

- There are generally two types of concrete pump hopper agitator motors: electric motors and hydraulic motors. Electric motors are powered by electricity and are commonly used in smaller and portable concrete pumps. Hydraulic motors, on the other hand, are driven by hydraulic power generated by the concrete pump itself and are typically used in larger and stationary concrete pumps.

- Q:Can concrete pump valves be repaired or should they be replaced?

- Instead of being replaced, concrete pump valves can frequently undergo repair. The determination of whether to repair or replace a concrete pump valve is contingent upon the extent of the damage and the cost-effectiveness of each alternative. Occasionally, minor problems like clogs or leaks can be effortlessly resolved by cleaning or substituting smaller parts. Nevertheless, if the valve is significantly impaired or deteriorated, replacement might be the more pragmatic resolution. It is advisable to seek the expertise of a professional concrete pump technician to evaluate the valve's condition and ascertain the most suitable course of action.

- Q:How often should hydraulic filters be replaced in a concrete pump?

- To ensure optimal performance and longevity of the equipment, it is important to regularly replace the hydraulic filters in a concrete pump. The frequency of replacement will depend on factors such as the specific model of the concrete pump, the operating conditions, and the quality of hydraulic fluid used. As a general rule, it is recommended to replace the hydraulic filters every 500 to 1,000 operating hours or at least once a year, whichever comes first. However, it is crucial to consult the manufacturer's recommendations and guidelines for the specific model of the concrete pump, as they may have specific maintenance schedules and intervals. Regularly inspecting the hydraulic filters is also vital to determine if replacement is necessary before the recommended interval. If the filters are clogged, damaged, or show signs of excessive wear, immediate replacement is necessary to prevent potential damage to the hydraulic system. Additionally, if the concrete pump operates in harsh or dusty environments, more frequent filter replacements may be required to ensure proper filtration and prevent contamination. In conclusion, timely and proper replacement of hydraulic filters in a concrete pump is crucial to maintain efficiency and reliability, prevent breakdowns, and prolong the service life of the equipment.

- Q:How can a faulty gearbox affect the pump's performance?

- A faulty gearbox can negatively affect the pump's performance by causing issues such as uneven rotation, decreased efficiency, increased noise, and possible breakdowns.

- Q:What is the function of a concrete pump hopper agitator shaft bearing?

- The function of a concrete pump hopper agitator shaft bearing is to provide support and allow for smooth rotation of the agitator shaft. The bearing is typically made of a durable material, such as steel or bronze, and is designed to withstand heavy loads and vibrations. It helps to reduce friction and prevent the agitator shaft from seizing or wearing out prematurely. Additionally, the bearing helps to maintain the alignment of the shaft, ensuring efficient mixing of the concrete in the hopper. Overall, the concrete pump hopper agitator shaft bearing plays a crucial role in the proper functioning of the pump, ensuring reliable and consistent performance.

- Q:How does a hydraulic oil cooler maintain optimal temperature in a concrete pump?

- A hydraulic oil cooler plays a crucial role in maintaining optimal temperature in a concrete pump by effectively dissipating heat generated during the hydraulic system's operation. As the hydraulic system of a concrete pump is continuously subjected to high pressure and heavy loads, the oil within the system tends to heat up rapidly. If the oil temperature exceeds the recommended range, it can lead to a decrease in overall system efficiency, increased wear and tear of components, and potential system failure. To prevent these issues, a hydraulic oil cooler is installed in the concrete pump. It works by utilizing a heat exchanger that transfers the excessive heat from the hydraulic oil to the surrounding air or another cooling medium, such as water or a refrigerant. This heat exchange process helps to lower the temperature of the hydraulic oil, maintaining it within the optimal operating range. The hydraulic oil cooler typically consists of a series of fins or tubes through which the hot oil flows. These fins or tubes increase the surface area of contact between the oil and the cooling medium, allowing for efficient heat transfer. Additionally, a fan or a pump may be used to enhance the airflow or flow of the cooling medium, further improving the cooling process. By maintaining the hydraulic oil at an optimal temperature, the hydraulic oil cooler ensures that the concrete pump operates at its peak performance. This not only increases the overall efficiency and productivity of the pump but also prolongs the lifespan of critical components. Moreover, by preventing overheating, the hydraulic oil cooler helps to minimize the risk of costly and unexpected downtime due to system failure. In conclusion, a hydraulic oil cooler is an essential component in a concrete pump that maintains optimal temperature by dissipating excessive heat from the hydraulic oil. By effectively cooling the oil, it ensures the smooth operation, efficiency, and longevity of the hydraulic system, ultimately contributing to the overall productivity and reliability of the concrete pump.

- Q:How long do concrete pump spare parts typically last?

- The lifespan of concrete pump spare parts can vary depending on several factors such as usage frequency, maintenance practices, and the quality of the parts. However, on average, concrete pump spare parts are designed to last for several years before requiring replacement.

- Q:How can a malfunctioning control lever affect the pump's operation?

- A malfunctioning control lever can significantly impact the pump's operation. It may cause the pump to operate at incorrect speeds, resulting in inefficient performance or potential damage to the pump. Additionally, a malfunctioning control lever can lead to improper fluid flow control, leading to inconsistent or inaccurate output. Overall, it is crucial to promptly address any issues with the control lever to ensure the pump operates reliably and efficiently.

- Q:How do I troubleshoot common problems with concrete pump spare parts?

- Troubleshooting common problems with concrete pump spare parts can be done through a systematic approach. Here are some steps to help you identify and resolve issues: 1. Identify the problem: Start by observing the symptoms and identifying the specific issue you are facing. This can include leaks, reduced pumping efficiency, abnormal noise, or power failure. 2. Check for clogs or blockages: Inspect the pump's hoses, pipes, and valves for any clogs or blockages that may be hindering the flow of concrete. Clear out any debris or obstructions that you find. 3. Inspect the wear parts: Examine the wear parts such as the pump's pistons, seals, or gaskets. Look for signs of wear and tear, cracks, or damage. If necessary, replace any worn-out parts. 4. Check for air leaks: Air leaks can affect the pump's performance and efficiency. Inspect the fittings, connections, and seals for any signs of air leakage. Tighten loose fittings or replace faulty seals as needed. 5. Ensure proper lubrication: Lack of lubrication can cause friction and damage to the pump's moving parts. Check the lubrication system and ensure that it is functioning properly. Add lubricant if necessary. 6. Verify electrical connections: If you are experiencing power failure or electrical issues, check the electrical connections of the pump. Look for loose or damaged wires and connections. Repair or replace any faulty components. 7. Consult the manufacturer's manual: The manufacturer's manual can provide valuable troubleshooting information specific to your concrete pump spare parts. Refer to the manual to understand the recommended maintenance procedures and troubleshooting steps. 8. Seek professional assistance if needed: If you are unable to identify or resolve the issue on your own, it is advisable to seek professional assistance. Contact a qualified technician or the manufacturer's customer support for further guidance and support. Remember, regular maintenance and proper usage of concrete pump spare parts can minimize the occurrence of problems.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Pump Truck Parts Delivery Pipe Normal Pipe DN125 3MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords