Concrete Pump ELBOW R275, DGR 90 DN100 with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

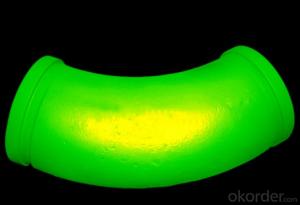

Product Name: Concrete Pump ELBOW R275, DGR 90 DN100

1. Specification

Dimensions: DN100MM

Radius: 275mm,1000mm

Flange: SK, ZX, F&M

Degree: 30°, 45°, 90°

Material: #20 steel, ST52, Mn 13-4

Thickness: 4.5mm,6mm,7.1mm,7.5mm,10mm,

Working pressure: 180MPa

Notes: total series of concrete pump clamp for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

2. Application of Concrete Pump Bend DN125

Concrete Pump ELBOW R275, DGR 90 DN100widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery of Concrete Pump Bends

Every 60pcs Concrete Pump Bend DN125 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump ELBOW R275, DGR 90 DN100 according to customers request?

A4: Yes, we can produce Concrete Pump ELBOW R275, DGR 90 DN100 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: What is the function of a concrete pump outrigger?

- The function of a concrete pump outrigger is to provide stability and support to the concrete pump while it is in operation. The outrigger extends from the sides of the pump and is used to distribute the weight of the pump and concrete being pumped, preventing it from tipping over or causing any instability.

- Q: How do I find the right part number for a specific concrete pump spare part?

- To find the right part number for a specific concrete pump spare part, you can follow these steps: 1. Start by identifying the make and model of your concrete pump. This information is usually found on the pump itself or in the product documentation. 2. Once you have the make and model, visit the manufacturer's website or contact their customer support directly. They will typically have a parts catalog or database where you can search for the specific part you need. 3. Use the provided search tool or browse through the catalog to find the section related to your concrete pump model. Look for the parts that match your description or function. 4. Pay attention to the part numbers listed alongside the descriptions. These numbers are usually unique identifiers for each specific part. Make note of the part number(s) that match the spare part you require. 5. If you are unable to find the required part number on the manufacturer's website or catalog, consider reaching out to authorized dealers or distributors of the concrete pump brand. They may have additional resources or access to parts that are not readily available elsewhere. By following these steps and utilizing the manufacturer's resources, you should be able to find the right part number for your specific concrete pump spare part.

- Q: Are there any specific guidelines for the installation of control valves or solenoids in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of control valves or solenoids in concrete pump spare parts. These guidelines typically include proper alignment, mounting, and connection procedures to ensure optimal performance and longevity of the components. Additionally, it is important to follow manufacturer's instructions and recommendations for the specific model of control valve or solenoid being installed.

- Q: What are the signs of a faulty concrete pump control box?

- Some signs of a faulty concrete pump control box may include malfunctioning buttons or switches, erratic or inconsistent pump operation, failure to start or stop the pump, and abnormal or unusual sounds coming from the control box. Additionally, if there are any visible signs of damage, such as loose wires or burnt components, it could indicate a problem with the control box.

- Q: Are there any warranties or guarantees available for concrete pump spare parts?

- Yes, there are warranties and guarantees available for concrete pump spare parts. Many reputable manufacturers and suppliers offer warranties on their products, providing assurance of quality and performance. These warranties typically cover defects in materials or workmanship and may vary in duration and terms. It is advisable to inquire about the specific warranty or guarantee offered by the supplier before purchasing concrete pump spare parts.

- Q: Are there any specific troubleshooting steps for identifying issues with concrete pump spare parts?

- Yes, there are specific troubleshooting steps that can be followed to identify issues with concrete pump spare parts. 1. Visual Inspection: Conduct a thorough visual inspection of the spare parts, looking for any signs of wear, damage, or misalignment. Check for cracks, breaks, or any other visible signs of damage. 2. Functionality Test: Test the functionality of the spare parts by operating the concrete pump. Pay attention to any abnormal noises, vibrations, or irregular movements. This can help identify issues with the spare parts. 3. Pressure Test: Perform a pressure test to ensure that the spare parts can handle the required pressure. This can be done by connecting a pressure gauge to the pump and checking if it reaches the desired pressure levels. Any abnormal pressure fluctuations can indicate issues with the spare parts. 4. Flow Test: Conduct a flow test to evaluate the flow rate of the concrete through the pump. Check if the flow is consistent and smooth. Any blockages or irregular flow patterns can indicate issues with the spare parts. 5. Check for Leaks: Inspect the spare parts for any leaks or fluid seepage. Leaks can indicate faulty seals, gaskets, or fittings. Use a suitable leak detection method, such as using a dye or pressure test, to identify the source of the leak. 6. Consult Technical Manuals: Refer to the technical manuals provided by the manufacturer for troubleshooting guidelines specific to the concrete pump spare parts. These manuals often contain detailed troubleshooting steps and recommended solutions for common issues. 7. Seek Expert Advice: If you are unable to identify the issue or troubleshoot effectively, it is advisable to consult with a qualified technician or the manufacturer's technical support team. They can provide expert guidance and assistance in identifying and resolving complex issues with concrete pump spare parts. By following these troubleshooting steps, it becomes easier to identify any issues with concrete pump spare parts and take appropriate measures to address them promptly.

- Q: Can I get spare parts for both single-cylinder and multi-cylinder concrete pumps?

- Yes, you can get spare parts for both single-cylinder and multi-cylinder concrete pumps. Many manufacturers and suppliers offer spare parts for different types of concrete pumps, including both single-cylinder and multi-cylinder models. These spare parts can include components such as hydraulic cylinders, pistons, seals, valves, hoses, and other essential parts that may need replacement due to wear and tear or damage. It is essential to reach out to the specific manufacturer or supplier of your concrete pump to inquire about the availability and compatibility of spare parts for your particular model.

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- Hydraulic cylinders in a concrete pump should be inspected regularly, ideally every 500 hours of operation or at least once a year, whichever comes first. However, it is important to note that the frequency of inspections may vary depending on the specific conditions and usage of the concrete pump. During inspections, qualified technicians should thoroughly examine the hydraulic cylinders for any signs of wear, damage, or leaks. They should also check the alignment, piston rods, seals, and other components to ensure proper functioning. If any issues are found, such as excessive wear or leaks, it is recommended to replace the hydraulic cylinders promptly to prevent further damage and maintain optimal performance. Regular inspections and timely replacements of hydraulic cylinders are crucial for ensuring the safety, efficiency, and longevity of a concrete pump. Neglecting proper maintenance can lead to costly repairs, decreased productivity, and even accidents. Therefore, it is essential to follow manufacturer's guidelines and consult with professionals to determine the appropriate inspection and replacement intervals for hydraulic cylinders in a concrete pump.

- Q: Can I get spare parts for both piston and rotary concrete pumps?

- Yes, you can get spare parts for both piston and rotary concrete pumps. Many manufacturers and suppliers offer a wide range of spare parts for these types of pumps. These parts include but are not limited to pistons, seals, valves, wear plates, hydraulic components, and bearings. It is important to ensure that you purchase genuine spare parts from reputable suppliers to ensure the quality and compatibility with your specific pump model. Additionally, it is recommended to have a regular maintenance and inspection schedule for your concrete pump to identify any worn-out parts and replace them promptly to avoid any potential breakdowns or disruptions in your construction projects.

- Q: How can one identify the need for replacement of concrete pump spare parts?

- One can identify the need for replacement of concrete pump spare parts by observing certain signs and conducting regular maintenance checks. Firstly, it is important to monitor the performance of the concrete pump. If there is a decrease in efficiency or a significant drop in the output of the pump, it could indicate the need for replacement parts. This could be due to worn-out components that are affecting the pump's ability to deliver concrete effectively. Another sign to look for is abnormal noise coming from the pump. Unusual or excessive noise can indicate problems with the moving parts, such as bearings or seals, which may need to be replaced. Inspecting the wear and tear of the spare parts is also crucial. Components such as hoses, pipes, and seals can deteriorate over time due to the abrasive nature of concrete. If there are visible signs of wear, such as cracks, leaks, or bulges, it is likely that these parts need to be replaced. Regular maintenance checks are essential in identifying the need for replacement parts. This can involve checking the condition of key components, such as the piston, cylinder, and valves, and ensuring they are clean, properly lubricated, and functioning correctly. Any signs of damage, corrosion, or excessive wear should be addressed promptly to prevent further damage to the pump and the need for more extensive repairs. In summary, by closely monitoring the performance of the concrete pump, listening for abnormal noise, inspecting for wear and tear, and conducting regular maintenance checks, one can effectively identify the need for replacement of concrete pump spare parts. Timely replacement of these parts can help maintain the pump's efficiency and prolong its lifespan.

Send your message to us

Concrete Pump ELBOW R275, DGR 90 DN100 with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords