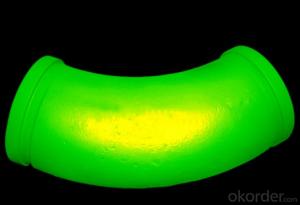

Concrete Pump Elbow R275, DN125MM Grey with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Concrete Pump ELBOW R2751. Specification

Dimensions: DN100MM

Radius: 275mm,1000mm

Flange: SK, ZX, F&M

Degree: 30°, 45°, 90°

Material: #20 steel, ST52, Mn 13-4

Thickness: 4.5mm,6mm,7.1mm,7.5mm,10mm,

Working pressure: 180MPa

Notes: total series of concrete pump clamp for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

2. Application of Concrete Pump Bend DN125

Concrete Pump ELBOW R275 widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery of Concrete Pump Bends

Every 60pcs Concrete Pump ELBOW R275 put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some Concrete Pump ELBOW R275 according to customers request?

A4: Yes, we can produce Concrete Pump ELBOW R275 according to the difference country situations and different concrete pump to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5:We have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Images:

- Q: How can one differentiate between genuine and counterfeit concrete pump spare parts?

- To differentiate between genuine and counterfeit concrete pump spare parts, one should consider several factors. Firstly, it is crucial to purchase spare parts from authorized and reputable dealers or manufacturers. Genuine parts are typically sold through official channels, ensuring their authenticity and quality. Secondly, one should carefully inspect the packaging and labeling of the spare parts. Genuine parts often have clear branding, product numbers, and proper packaging, while counterfeit parts may have inconsistent labeling or poor quality packaging. Additionally, examining the quality and durability of the spare parts is essential. Genuine parts are manufactured to meet strict standards and are more likely to be durable and reliable. Lastly, seeking professional advice or consulting with experts in the industry can provide valuable insights into identifying genuine concrete pump spare parts.

- Q: Are there any maintenance tips to extend the lifespan of concrete pump spare parts?

- Yes, there are several maintenance tips that can help extend the lifespan of concrete pump spare parts. 1. Regular Cleaning: It is important to regularly clean the spare parts to remove any dirt, debris, or concrete buildup. This can be done using a brush, water, and mild detergent. Cleaning helps prevent corrosion and ensures smooth operation. 2. Lubrication: Proper lubrication of moving parts is crucial to reduce friction and wear. It is important to follow the manufacturer's recommendations for lubrication intervals and use high-quality lubricants. Regularly inspect the lubrication points and replace any worn-out or damaged lubrication components. 3. Inspections and Maintenance: Regular inspections of all spare parts are necessary to identify any signs of wear, damage, or misalignment. Any issues should be repaired or replaced promptly. Additionally, following the maintenance schedule provided by the manufacturer is essential to address any potential problems before they escalate. 4. Proper Storage: When not in use, spare parts should be stored in a clean and dry environment to prevent rust and corrosion. They should be protected from extreme temperatures, moisture, and direct sunlight. Additionally, spare parts should be stored in a way that prevents any damage or deformation. 5. Correct Usage: It is crucial to operate the concrete pump in accordance with the manufacturer's guidelines. Overloading, excessive pressure, or improper operation can lead to premature wear and damage to the spare parts. Proper training should be provided to the operators to ensure they understand the correct usage techniques. 6. Regular Maintenance of the Concrete Pump: The overall condition of the concrete pump can have an impact on the lifespan of the spare parts. Regular maintenance of the pump, including cleaning, lubrication, and inspections, can help identify and address any potential issues that may affect the spare parts. By following these maintenance tips, the lifespan of concrete pump spare parts can be extended, reducing the need for frequent replacements and saving costs in the long run.

- Q: What is the role of a concrete pump cylinder in a pumping system?

- The role of a concrete pump cylinder in a pumping system is to generate the necessary pressure and force required to transport concrete from the hopper or storage container to the desired location. The cylinder plays a crucial role in the pumping process by creating a reciprocating motion that helps in pushing the concrete through the pipeline. The concrete pump cylinder is typically connected to a piston, which moves back and forth inside the cylinder to create the pumping action. As the piston moves towards the outlet end of the cylinder, it creates a vacuum that sucks in the concrete from the hopper. When the piston moves in the opposite direction, it compresses the concrete and forces it out through the outlet valve, into the pipeline, and ultimately to the designated area. The size and design of the concrete pump cylinder depend on various factors such as the desired pumping capacity, the distance the concrete needs to be transported, and the viscosity of the concrete mix. It is essential for the cylinder to be strong and durable to withstand the high pressures and repetitive movements involved in the pumping process. In summary, the concrete pump cylinder is responsible for generating the necessary pressure and force to transport concrete efficiently and effectively. It forms the backbone of the pumping system, enabling the smooth and continuous flow of concrete from the hopper to the desired location.

- Q: How can a faulty concrete pump S valve affect the concrete flow?

- A faulty concrete pump S valve can affect the concrete flow by causing disruptions, blockages, or uneven distribution of the concrete. The S valve is responsible for controlling the direction of the concrete flow, and when it malfunctions, it can lead to decreased or inconsistent flow rates. This can result in delays in the construction process, poor concrete quality, or even damage to the pump system.

- Q: How do I properly maintain and replace rubber pistons in concrete pump spare parts?

- Maintaining and replacing rubber pistons in concrete pump spare parts is crucial for the efficient operation of the pump and to ensure a longer lifespan of the equipment. Here are some steps to properly maintain and replace rubber pistons in concrete pump spare parts: 1. Regular Inspection: It is important to inspect the rubber pistons regularly to identify any signs of wear or damage. Look for cracks, tears, or any other visible signs of deterioration. 2. Cleaning: Before replacing the rubber pistons, make sure to thoroughly clean the area around the pistons. Remove any dirt, debris, or concrete residue that may be present. This will help prevent contamination and ensure a proper fit for the new pistons. 3. Proper Lubrication: Apply a suitable lubricant to the rubber pistons to ensure smooth operation and reduce friction. This will help prolong the life of the pistons and prevent premature wear. 4. Correct Installation: When replacing the rubber pistons, ensure they are properly installed according to the manufacturer's instructions. Use the correct tools and techniques to avoid damaging the pistons or other components of the pump. 5. Quality Replacement Parts: Always use high-quality replacement rubber pistons from reputable suppliers. Inferior quality pistons may not perform as well and could result in frequent replacements or damage to the pump. 6. Regular Maintenance: Implement a regular maintenance schedule for your concrete pump, including the rubber pistons. This can include cleaning, lubrication, and inspection of the pistons to identify any signs of wear or damage before they become major issues. 7. Training and Expertise: Ensure that the person responsible for maintaining and replacing the rubber pistons has the necessary training and expertise. This will help ensure the job is done correctly and minimize the risk of damage to the pump or injury to personnel. By following these steps, you can properly maintain and replace rubber pistons in concrete pump spare parts, ensuring optimal performance and longevity of the equipment.

- Q: How can the concrete pump pipe be cleaned?

- Secure the cover at the end of the pipe so that the concrete does not hurt.

- Q: What are the elements of concrete pump and concrete pump truck selection?

- The amount of concrete pump used in the construction business can be calculated according to the concrete pouring amount, the actual transport capacity of the single machine and the construction operation time. For those concrete pumping projects with a large amount of disposable concrete, besides the calculation and determination, there should be a certain reserve. In addition, an annual output of 10~15 million M3 concrete mixing plant, 2~3 equipment needs to be equipped with concrete pump vehicles

- Q: How often should concrete pump water pumps be inspected and replaced?

- Concrete pump water pumps should be inspected regularly, ideally on a monthly basis, to ensure they are functioning properly and to catch any potential issues early on. However, the frequency of replacement will depend on various factors such as the pump's usage, maintenance, and overall condition. It is recommended to consult the manufacturer's guidelines and seek professional advice for determining the specific replacement schedule for concrete pump water pumps.

- Q: How is the piping of the concrete pipe designed?

- When pumping underground structures, the horizontal axis of the ground shall be perpendicular to the axis of the Y - shaped discharge port

- Q: How often should hopper grate pins be inspected or replaced in a concrete pump?

- To maintain proper functioning and prevent potential problems, it is important to regularly inspect the hopper grate pins in a concrete pump. A suggested guideline is to inspect these pins at least once a month or after every 200 hours of operation, whichever comes first. However, the inspection frequency may vary based on the specific conditions and usage of the concrete pump. During the inspection, it is crucial to examine the hopper grate pins for any signs of wear, damage, or deformities. If any issues are discovered, they should be promptly addressed to prevent further damage and ensure the safe and efficient operation of the concrete pump. When significant signs of wear or damage are observed in the hopper grate pins, it is necessary to replace them immediately to maintain their functionality. It is important to follow the manufacturer's guidelines and recommendations for replacing these pins, as they may differ depending on the specific model and design of the concrete pump. By conducting regular inspections and replacing hopper grate pins in a timely manner, the longevity and reliability of the concrete pump can be enhanced, reducing the risk of unexpected breakdowns and ensuring optimal performance.

Send your message to us

Concrete Pump Elbow R275, DN125MM Grey with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords