Concrete Pump Cleaning Ball DN125 with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

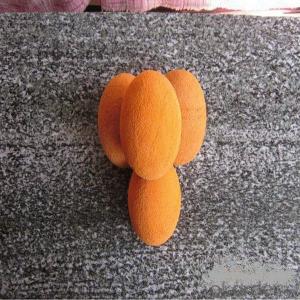

Product Name: Concrete Pump Cleaning Ball DN125 with Good Quality

1. Specification

Size | DN50 (2inch) OD: 60mm, soft/ hard/ medium soft |

DN80 (3inch) OD: 95mm, soft/ hard/ medium soft | |

DN100 (4inch) OD: 124mm, soft/ hard/ medium soft | |

DN125 (5inch) OD: 150mm, soft/ hard/ medium soft | |

DN150 (6inch) OD: 175mm, soft/ hard/ medium soft | |

Other specification is available according to your requirements. | |

Material | Natural rubber |

Application | Cleaning the pipeline of concrete pump and concrete pump truck in construction work equirement |

Serving brand of concrete pump | Sany, Zoomlion, Schwing, PM. CIFA etc |

2. Application

1.Applacation:cleaning the concrete pump pipeline

3. Package

Put into containers.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products have its ISO certifications, adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce Concrete Pump Cleaning Ball DN125 with Good Quality according to customers request?

A4: Yes, we can produce Concrete Pump Cleaning Ball DN125 with Good Quality according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: We have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities &skilled personnel at site for training.

Image

- Q: Are there any maintenance tips to extend the lifespan of concrete pump spare parts?

- Yes, there are several maintenance tips to extend the lifespan of concrete pump spare parts. Regular cleaning and lubrication of the parts, proper storage to prevent corrosion, and routine inspection for wear and tear are essential. Additionally, using high-quality spare parts and following manufacturer's guidelines for maintenance and operation can significantly increase their longevity.

- Q: How can I minimize downtime during the replacement of concrete pump spare parts?

- To minimize downtime during the replacement of concrete pump spare parts, it is crucial to follow a few key steps. First, ensure that you have a comprehensive understanding of the specific spare parts required for your concrete pump. This will help you streamline the ordering process and minimize delays. Additionally, it is essential to schedule regular maintenance and inspections to identify any potential issues beforehand, allowing you to proactively replace parts before they fail. Lastly, work with a reputable supplier who can provide high-quality spare parts promptly, reducing downtime.

- Q: Can concrete pump spare parts be repaired or refurbished?

- Yes, concrete pump spare parts can be repaired or refurbished. Many common spare parts such as seals, bearings, valves, and hydraulic components can be repaired or refurbished to extend their lifespan and save costs. Repairing or refurbishing these parts can involve replacing worn-out or damaged components, reconditioning or re-machining certain parts, and performing necessary maintenance and testing to ensure their proper functionality. Additionally, some manufacturers or specialized companies may offer services for repairing or refurbishing specific concrete pump spare parts, allowing for a more cost-effective solution compared to purchasing brand new parts. However, it is important to note that not all spare parts can be repaired or refurbished, especially if they are severely damaged or have exceeded their recommended service life. In such cases, it may be more practical and safer to replace the parts with new ones.

- Q: What are the key factors to consider when purchasing concrete pump spare parts?

- When purchasing concrete pump spare parts, there are several key factors that need to be considered to ensure you make the right choice. These factors include: 1. Quality: The quality of the spare parts is crucial as it directly impacts the performance and longevity of your concrete pump. Look for high-quality materials and reputable brands to ensure durability and reliability. 2. Compatibility: It is essential to ensure that the spare parts you purchase are compatible with your specific concrete pump model. Check the specifications and consult with experts or the manufacturer to avoid any compatibility issues. 3. Cost-effectiveness: While it is important to consider the price of the spare parts, it should not be the sole determining factor. Look for a balance between cost and quality to ensure that you are getting value for your money in the long run. 4. Supplier reputation: Choose a reliable and reputable supplier who has a track record of providing genuine and high-quality spare parts. Read customer reviews, check their certifications, and consider their experience in the industry. 5. Availability and lead time: Ensure that the spare parts you need are readily available and can be delivered within a reasonable time frame. This is crucial to avoid delays in your construction projects and minimize downtime. 6. Warranty and after-sales support: Check if the spare parts come with a warranty or guarantee. Additionally, consider the availability of after-sales support and technical assistance in case you need any help or guidance during installation or maintenance. 7. Maintenance requirements: Consider the maintenance requirements of the spare parts you are purchasing. Look for components that are easy to install, maintain, and repair, as this can save you time and money in the long run. By considering these key factors, you can make an informed decision and ensure that you purchase the right concrete pump spare parts that meet your specific needs and requirements.

- Q: What is the function of a concrete pump hopper filter?

- Preventing damage and blockages, the concrete pump hopper filter's main function is to keep large debris, like rocks, out of the pump. It acts as a barrier between the hopper and the pump, ensuring that only properly sized aggregate and concrete mixture is pumped through. By reducing the risk of clogs and wear on the equipment, the filter helps maintain the pump's efficiency and longevity. Moreover, it removes unwanted contaminants, thus preserving the quality of the pumped concrete. In construction projects, the concrete pump hopper filter plays a crucial role in safeguarding the pump and ensuring a seamless and uninterrupted flow of concrete.

- Q: What is the role of a concrete pump hopper grate spring?

- The role of a concrete pump hopper grate spring is to provide tension and support to the hopper grate, ensuring that it remains securely in place while allowing for smooth and consistent flow of concrete through the pump.

- Q: How often should concrete pump clamps be inspected and replaced?

- To maintain proper functioning and detect any wear or damage, it is crucial to conduct regular inspections of concrete pump clamps. The inspection frequency will depend on factors like usage frequency, concrete type, and working conditions. As a general rule, it is advisable to inspect the clamps at least once a month or after every 100 hours of operation, whichever occurs first. This proactive approach will help identify any potential problems early on, preventing them from escalating into major issues. Furthermore, it is essential to visually examine the clamps before each use for any visible signs of damage or wear. This includes checking for cracks, deformations, and loose or missing bolts. The lifespan of concrete pump clamps can vary depending on factors such as clamp quality, intensity of use, and maintenance practices. However, as a general guideline, it is recommended to replace the clamps every 1-2 years or sooner if significant wear or damage is evident. Regular inspections and timely replacements of concrete pump clamps are crucial for ensuring safe and efficient pumping operations. Taking a proactive approach and promptly addressing any potential issues is always preferable to avoid costly repairs or accidents.

- Q: How often should hopper grate pins be inspected or replaced in a concrete pump?

- Hopper grate pins in a concrete pump should be inspected regularly, ideally before each use, to ensure they are in good condition. Depending on the frequency of usage and the material being pumped, replacement may be needed every few months or as soon as signs of wear and tear are observed.

- Q: What are the different types of concrete pump rubber pistons?

- In the market, one can find a variety of concrete pump rubber pistons, each with its own purpose and specifications. Commonly used types include: 1. Single-Action Piston: This piston is designed to push the concrete forward during pumping. It moves in one direction, ensuring a consistent and efficient flow of concrete. 2. Double-Action Piston: Unlike the single-action piston, this one can move in both directions. It offers more versatility in pumping, especially when there are obstacles or restrictions in the pump line. 3. Steel Reinforced Piston: To provide extra strength and durability, these pistons are reinforced with steel. They are often used for high-pressure pumping or when handling abrasive materials. 4. Polyurethane Piston: These pistons are known for their exceptional wear resistance and long lifespan. They are commonly used in demanding pumping conditions where durability is crucial. 5. Rubber Sponge Piston: Designed with a soft and flexible surface, rubber sponge pistons can conform to irregularities in the pump line. They are particularly useful for navigating bends or corners in the line. 6. Bonded Piston: Bonded pistons are created by bonding a rubber or polyurethane material to a metal core. This combination offers the flexibility of rubber and the strength of metal, making them suitable for a variety of pumping applications. Choosing the right concrete pump rubber piston is crucial for project success. Factors such as pumping pressure, material being pumped, and environmental conditions should be taken into account to ensure optimal performance and longevity of the piston.

- Q: How can a faulty oil cooler affect the pump's hydraulic system?

- A faulty oil cooler can affect the pump's hydraulic system by causing the hydraulic fluid to overheat. When the oil cooler fails to properly cool down the hydraulic fluid, it can lead to an increase in temperature within the system. This can result in a decrease in the hydraulic fluid's viscosity, leading to reduced lubrication and increased wear and tear on the pump's components. Additionally, overheated hydraulic fluid can also lead to the degradation of seals and O-rings, causing leaks and further damage to the pump.

Send your message to us

Concrete Pump Cleaning Ball DN125 with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords