RUBBER END HOSES 3 METERS

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

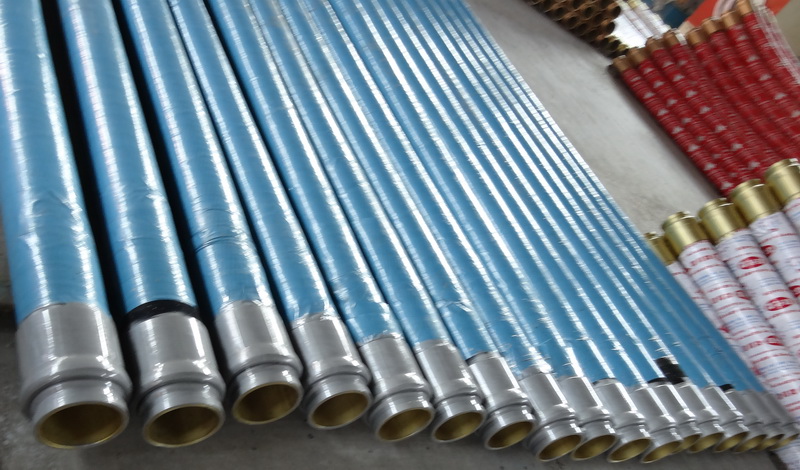

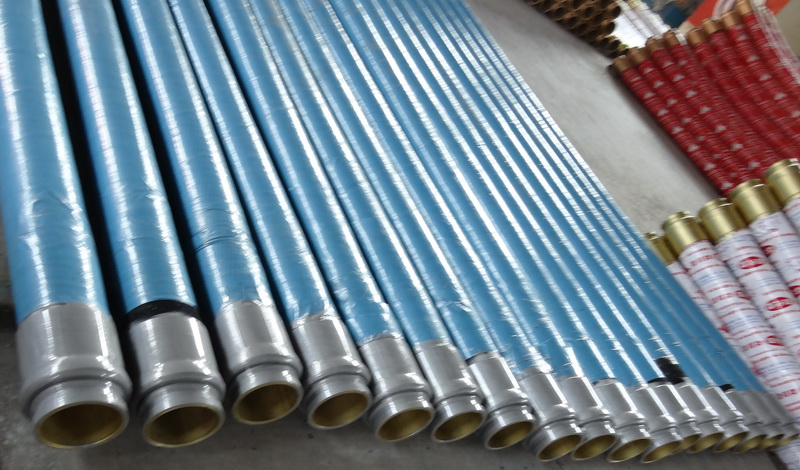

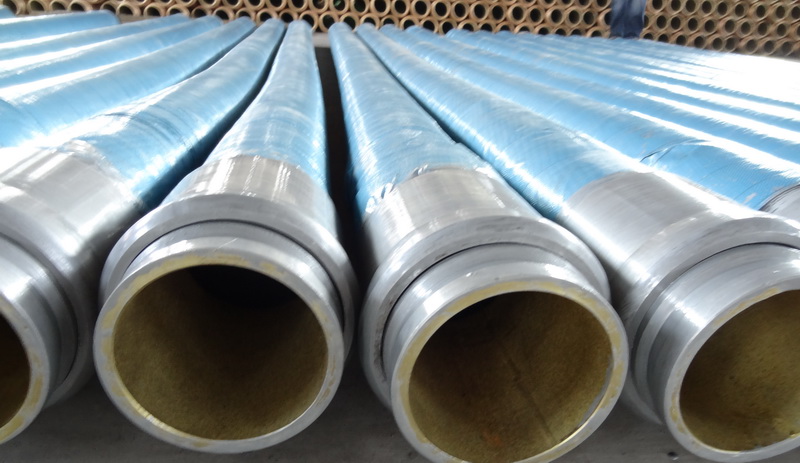

Product Name: Rubber End Hose 5’’ 3M

1. Specification

Type: 2 layers steel wire or 4 layers steel wire

working pressure: 85bar or 1232PSI

Dimensions: DN100MM, DN125MM, DN150MM, 4'', 5", 6''

Flanges: Single end, or double ends

Coupling: Painted or Galvanized.

Different Length : 3m, 4m, 5m.

Notes: total series of rubber hose for different brand concrete pump available from us, different length of rubber hose as customers requirments .

2. Application

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery and placement pumping.

Our rubber hoses for concrete pump have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Aiming at the largest concrete pump parts manufacturer, and reliable, professional supplier in China, we can supply concrete pump elbows, delivery pipes, casting or forging couplings, end rubber hoses, rubber pistons, tungsten wear plates, delivery cylinders, and other hydraulic parts, one stop service for your concrete pump parts and accessory business.

3. Package and Delivery

Every 200pcs put in one 20 feet container.

4. Production

Our Concrete Pump rubber hoses are made with advanced technology of weaving and natural rubber formula.

5. Why choose us?

1) Brand-name Parts

2) Country of Origin

3) Competitive Price

4) Good Product Performance

5) Prompt Delivery

6) Quality Approvals

7) Good Reputation

8) Expedite Communication

9) Good Packaging

10) Distributorships Offered

11) One Step Service

12) Good Quality Service

13) Small Orders Accepted

14) Overseas Service Branches

- Q: Are there any safety considerations when using concrete pump spare parts?

- Concrete pump spare parts should be used with caution and with a focus on safety. High-quality parts that are compatible with the specific make and model of the pump are crucial. Using substandard or incorrect parts can lead to equipment failure, posing a danger to the operator and those nearby. Regular maintenance and inspection of the spare parts are also essential for safety. Checking for signs of wear or damage on a regular basis can help prevent accidents and equipment failure. It is vital to follow the manufacturer's guidelines for maintenance and replacement intervals. Adhering to safety procedures and protocols is a must when using concrete pump spare parts. This includes wearing appropriate personal protective equipment, such as safety goggles, gloves, and steel-toed boots. It is equally important to ensure that all operators receive proper training on equipment usage and understand the potential hazards involved. Safe operating practices are paramount when working with concrete pump spare parts. Maintaining a safe distance from the work area, ensuring the stability and security of the pump, and avoiding overloading or exceeding the recommended operating capacity are all crucial. By taking these safety considerations into account and following proper procedures, the risks associated with using concrete pump spare parts can be minimized. This ensures the safety of operators and workers on construction sites.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts can vary depending on the specific part in question. However, there are some general signs that can indicate when a concrete pump spare part is experiencing wear and tear. One common sign is visible damage or deterioration on the surface of the part. This can include cracks, chips, or dents on the outer layer of the spare part. These damages can occur due to regular use, exposure to harsh environmental conditions, or accidental impact during operation. Another sign is increased vibration or noise during operation. If a concrete pump spare part is experiencing wear and tear, it may start to produce unusual vibrations or noises that were not present when it was in good condition. This can be an indicator of internal damage or misalignment of the part, which can affect its overall performance and efficiency. Reduced performance or efficiency is also a common sign of wear and tear on concrete pump spare parts. If a part is experiencing wear and tear, it may not function as effectively as before, resulting in decreased pumping capacity, reduced flow rate, or inefficient operation. This can lead to delays in construction projects and increased maintenance costs. Additionally, increased maintenance and repair requirements can indicate wear and tear on concrete pump spare parts. If a part needs to be repaired or replaced more frequently than usual, it could be a sign that it is experiencing wear and tear. Regular inspections and maintenance can help identify potential issues early on and prevent further damage to the spare parts. In conclusion, signs of wear and tear on concrete pump spare parts can include visible damage, increased vibration or noise during operation, reduced performance or efficiency, and increased maintenance requirements. It is important to regularly inspect and maintain these spare parts to ensure their optimal performance and prolong their lifespan.

- Q: Can concrete pump spare parts be repaired or refurbished?

- Concrete pump spare parts have the potential to be repaired or refurbished. Spare parts such as seals, bearings, valves, and hydraulic components can undergo repair or refurbishment processes, which can effectively prolong their lifespan and result in cost savings. The repair or refurbishment of these parts may involve the replacement of worn-out or damaged components, the reconditioning or re-machining of certain parts, and the execution of necessary maintenance and testing procedures to ensure their proper functionality. Moreover, some manufacturers or specialized companies may provide services specifically for repairing or refurbishing specific concrete pump spare parts, offering a more cost-effective alternative to purchasing entirely new parts. Nevertheless, it is crucial to acknowledge that not all spare parts are suitable for repair or refurbishment, especially if they are severely damaged or have exceeded their recommended service life. In such circumstances, it may be more practical and safer to opt for the replacement of these parts with new ones.

- Q: How often should wear rings be replaced in a concrete pump?

- The frequency at which wear rings should be replaced in a concrete pump depends on several factors including the type of pump, the quality of the wear rings, the volume of concrete being pumped, and the operating conditions. In general, wear rings are components that experience significant wear and tear due to the abrasive nature of concrete. As a result, they will eventually need to be replaced to maintain the pump's efficiency and prevent potential damage to other parts of the pump. Typically, wear rings should be inspected regularly during routine maintenance checks. The wear patterns and extent of damage will determine whether replacement is necessary. In some cases, wear rings may last for several thousand hours of operation, while in others, replacement may be required more frequently. It is recommended to consult the pump manufacturer for specific guidelines on wear ring replacement intervals based on the pump model and operating conditions. They may provide recommendations based on their expertise and knowledge of the pump's design and performance. Ultimately, the goal is to ensure that the concrete pump operates smoothly and efficiently, minimizing downtime and maximizing its lifespan. Regular inspections and proactive replacement of wear rings when necessary will help achieve this objective.

- Q: Are there any specific warranty options available for concrete pump spare parts?

- Yes, there are specific warranty options available for concrete pump spare parts. Many manufacturers and suppliers offer warranties on their products to provide customers with peace of mind and assurance of quality. The specific warranty options may vary depending on the manufacturer or supplier, but they generally cover defects in materials or workmanship. It is recommended to carefully review the warranty terms and conditions before purchasing concrete pump spare parts to understand what is covered and for how long. Some warranties may provide a limited duration of coverage, while others may offer extended warranties for an additional cost. Additionally, it is important to follow the recommended maintenance and usage guidelines to ensure the warranty remains valid. In case of any issues or concerns with the spare parts during the warranty period, customers can typically contact the manufacturer or supplier for assistance.

- Q: What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q: How often should concrete pump lubrication systems be inspected and maintained?

- Concrete pump lubrication systems should be inspected and maintained regularly to ensure their proper functioning and longevity. The frequency of inspections and maintenance will depend on various factors such as the type of pump, its usage, and the manufacturer's recommendations. Generally, it is recommended to inspect and maintain concrete pump lubrication systems on a monthly basis. This allows for early detection of any potential issues or wear and tear that may require attention. Additionally, regular inspections can help identify any signs of lubricant degradation or contamination, which can impact the efficiency and performance of the system. During the inspection, it is important to check for any leaks, damaged or worn-out components, and ensure that all lubrication points are properly greased. The lubrication system should also be cleaned to remove any debris or contaminants that may have accumulated over time. In addition to monthly inspections, certain maintenance tasks should be performed at regular intervals. This may include changing the lubricant and filters, adjusting or replacing belts and hoses, and checking the system for proper pressure and flow. It is important to note that the manufacturer's guidelines and recommendations should always be followed when it comes to inspecting and maintaining concrete pump lubrication systems. They may provide specific instructions based on the type and model of the pump, as well as any unique requirements. By regularly inspecting and maintaining concrete pump lubrication systems, you can ensure their optimal performance, minimize downtime, and extend their lifespan.

- Q: What is the importance of a good quality concrete pump seal?

- A good quality concrete pump seal is of utmost importance for several reasons. Firstly, it ensures the efficient and reliable functioning of the concrete pump. The seal is responsible for preventing any leakage or loss of pressure during the pumping process, which can lead to delays, inefficiencies, and potential damage to the pump itself. Moreover, a good quality seal helps maintain the integrity of the concrete being pumped. Concrete is a mixture of various materials, including water, cement, aggregates, and additives. To achieve the desired strength and durability, it is crucial that the concrete remains in its optimal state without any contamination or dilution. A high-quality seal prevents any external elements, such as water or air, from entering the pumping system and affecting the concrete's composition. Furthermore, a reliable seal contributes to the safety of the pumping operation. Concrete pumps are used in construction sites, where workers and equipment are present. Any failure or malfunction of the seal can lead to unexpected incidents, injuries, or damage to property. Therefore, a good quality seal provides peace of mind and reduces the risk of accidents. Lastly, investing in a good quality concrete pump seal can save both time and money in the long run. A durable and efficient seal minimizes the need for frequent replacements or repairs, reducing maintenance costs and downtime. It also ensures a smooth and continuous pumping process, allowing construction projects to be completed more efficiently and on schedule. In conclusion, a good quality concrete pump seal is crucial for the efficient functioning, integrity of the concrete, safety, and cost-effectiveness of a pumping operation. Therefore, it is essential to prioritize the selection and installation of a reliable seal to ensure the success and longevity of concrete pumping projects.

- Q: Which height of concrete pump is the most practical?

- The power of the concrete pump truck engine power is transmitted to the hydraulic pump or rear axle through the power transfer case, push the piston to drive the hydraulic pump concrete pump

- Q: What is the function of a concrete pump remote control antenna?

- The function of a concrete pump remote control antenna is to establish a wireless connection between the remote control device and the concrete pump. This allows the operator to remotely control the various functions of the concrete pump, such as starting and stopping the pump, adjusting the speed and flow of the concrete, and controlling the boom movements. The antenna receives signals from the remote control device and transmits them to the concrete pump, enabling the operator to control the pump from a safe distance. This helps improve efficiency, accuracy, and safety on construction sites by allowing the operator to have better visibility of the pump and its surroundings while still maintaining full control over its operations.

Send your message to us

RUBBER END HOSES 3 METERS

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords