Rebar Lengths Standard

Rebar Lengths Standard Related Searches

Rebar Identification Rebar Tensile Strength Rebar 10Mm Grade 80 Rebar 30M Rebar Ss Rebar T10 Rebar Blue Steel Rebar Rebar Coil Billet Steel Rebar Rebar Stirrups When Was Rebar Invented 18J Rebar Frp Rebar Pallet Standard Size 1.1Mx1.1M Gfrp Rebar Y16 Rebar Billet Rebar Astm A615 Grade 60 Rebar Ladle Refractory Materials Refractory Brick Canada Rubber Clamps Drainage Fittings Bowden Cable End Fittings Rubber Coupling Re Bars Environmental Liners Resistivity Meter Radiant Barrier Installation Pre Drilled Flat BarRebar Lengths Standard Supplier & Manufacturer from China

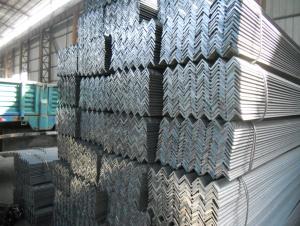

Rebar Lengths Standard encompasses a variety of steel reinforcement bars that are used in construction and civil engineering projects. These products are designed to provide structural integrity and support to concrete structures, ensuring their stability and durability. The standard lengths of rebar are commonly used in various applications such as residential and commercial buildings, bridges, and other infrastructure projects.Rebar Lengths Standard are essential in numerous construction scenarios, where they are utilized to reinforce concrete and prevent it from cracking or breaking under stress. These products are available in different diameters and grades, allowing for flexibility in their usage depending on the specific requirements of each project. They are used in both vertical and horizontal applications, such as in columns, beams, and slabs, to enhance the overall strength and resilience of the structure.

Okorder.com is a leading wholesale supplier of Rebar Lengths Standard, boasting a vast inventory that caters to the diverse needs of the construction industry. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products they offer meet the highest industry standards. Their extensive range of rebar lengths allows customers to find the perfect fit for their projects, making them a reliable choice for those seeking to source high-quality reinforcement materials.

Hot Products