High Alumina Silica Bricks and Silica Mortar for Hot Blast Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM Group is listed No.187 in on Fortune Global 500, 2020.

Refractory is one of the main products of the group. At the same time, under the globalization strategy, CNBM International is the exporter, logistic and local service supplier.

13 Refractory plants locate in 9 different cities

15 professor level senior engineers,239 engineers,5 senior experts committed Iron & Steel industry

Annual production capacity is over 400,000 tons.

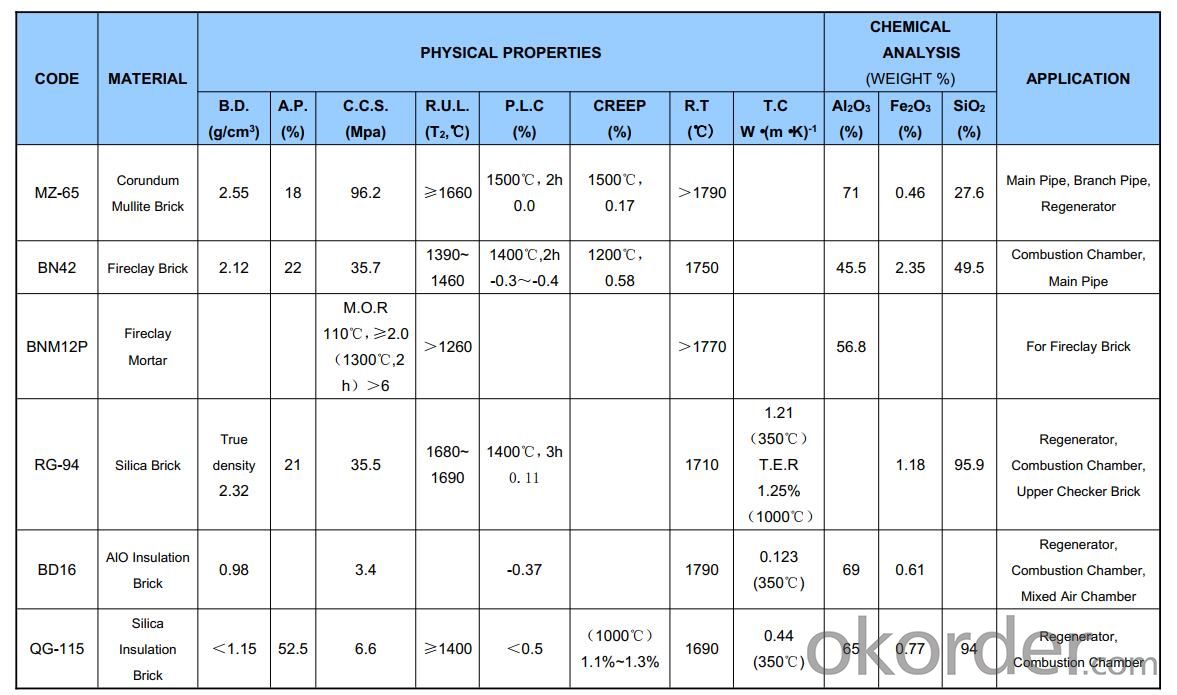

Product Name: Silica Bricks and Silica Mortar for Hot Blast Furnace

Features:

Low creep

Good thermal shock resistance

Good chemical corrosion resistance

Technical Data Sheet

Product Photos of 7-hole Low Creep Checker Bricks

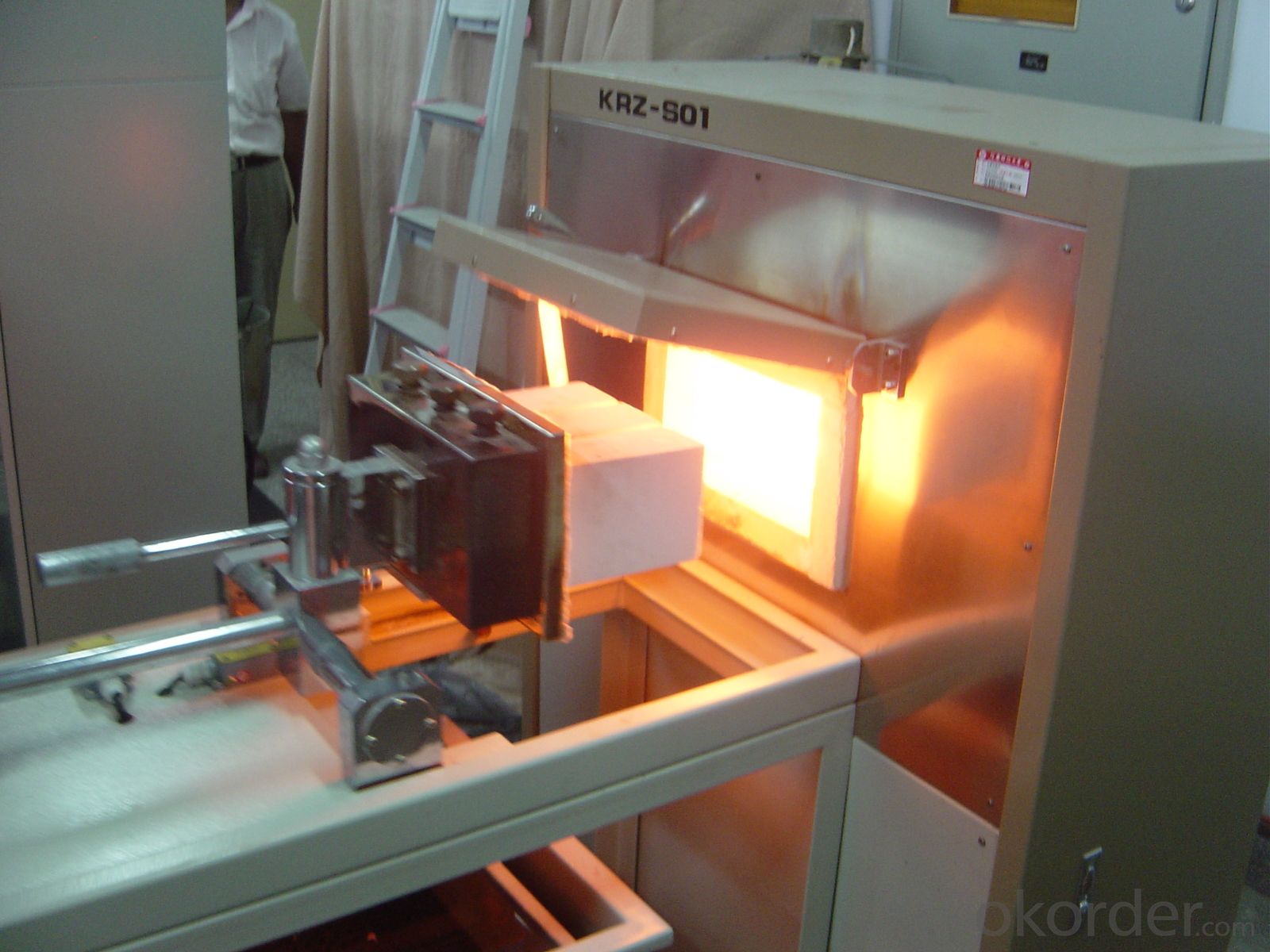

Our workshop

- Q: What are the requirements for Rubble backfill height?

- Backfill should be filled with large stones, big face, small face upward, the decoration is stable, and then use small stones leveling, the gap between the stones can be swept into the slag, gravel, so that the gap filled.

- Q: What is the standard size of high alumina brick?

- Standard brick: 230 x 115 x 65; four points: 230 x 115 x 40; three points: 230 x 115 x 30; 150 x 120: Brick gable. Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms.

- Q: What are the specific raw materials for plastic pallets?

- With excellent mechanical properties, its strength and elasticity are higher than HDPE, and it has good flexural fatigue resistance. It has good heat resistance and good chemical stability. Besides being concentrated by concentrated sulfuric acid and concentrated nitric acid, it is relatively stable to other chemical reagents. The high frequency insulation performance of polypropylene is excellent because of its almost no water absorption, so the insulation performance is not affected by temperature.

- Q: What are the characteristics of high alumina bricks?

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized high-temperature kilns and other energy consuming industries, such as chemical industry, electric power industry, etc.

- Q: How to reduce porosity of high alumina brick

- In order to reduce the porosity of high alumina brick, the corresponding measures should be taken from the selection of raw materials, batching, mixing, molding and firing.

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Referred to as refractory brick. Refractory wood made from refractory clay or other refractory material

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Refractoriness is the property of a refractory against high temperature, which means the temperature at which a refractory is softened to some extent after heating, but not its melting point. According to the degree of refractory, refractory materials can be divided into: General refractories, refractory degree is 1580 to 1770 DEG C; advanced refractories, refractory degree is 1770 to 2000 DEG C; special refractory material, refractory degree is greater than 2000 DEG C.

- Q: Is glass wool inorganic thermal insulation material?

- The characteristics of glass wool, glass wool is the molten glass fibrosis, the formation of cotton like material, chemical composition of glass, is a kind of inorganic fibers. With good forming, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- Fire clay -- usually refers to folk point stove furnace set with a kind of soil, limit under atmospheric pressure of 1500 degrees fire clay soil 1, properties and uses: clay brick of weak acid refractory material, its thermal stability is good, suitable for hot blast furnace, boiler and flue, smoke chamber lining, etc..2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

Send your message to us

High Alumina Silica Bricks and Silica Mortar for Hot Blast Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords