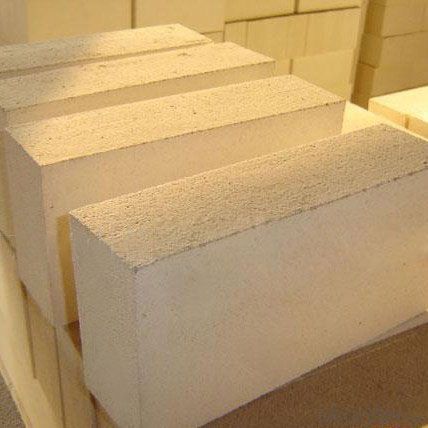

High Alumina Lightweight Insulating Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Lightweight Mullite insulating brick2.Manufacturer

3.ISO9001&CE

4.20 years experience of producing,researching,exporting

Lightweight mulite insulating brick

Lightweight mullite insulating brick

Density: 0.6-0.8g/cm3

Temperature: 1350-1550 degree

Al2O3: 45-60%

Stand Size: 230x114x65/75mm

Raw material of Lightweight mullite insulating brick:

JM insulating brick, using high pure mullite as raw material, is made by adding alumina powder according to different type and then sintered at high temperature. JM insulating brick is the new energy saving material for insulation.

CHARACTERISTIC of Lightweight mullite insulating brick:

Low density

High purity

Low thermal conductivity

Excellent thermal shock resistance

APPLICATION of Lightweight mullite insulating brick:

glass industries iron & steel industries

ceramics industries non-ferrous metals industries

electrolytic Aluminum industries power generation industries

Heat surface fireproof lining other fire-proof back lining

Tech Data of Lightweight mullite insulating brick:

Item | Lightweight Mullite insulating brick | ||

Index/Brand | JM-23 | JM-26 | JM-28 |

AL2O3, % ≥ | 45 | 52 | 60 |

Fe2O3, % ≤ | 0.8 | 0.6 | 0.6 |

Bulk density g/cm3 | 0.8 | 0.9 | 0.9-1.0 |

Cold crushing strength MPa | 2.1-3.0 | 3.0-4.0 | 6.0-7.0 |

Linear change after heating%(155O°C × 2h) | ±0.5 | ±0.5 | ±0.8 |

Thermal conductivity (350°C±25°C)(w/m·k) | 0.2-0.25 | 0.2-0.3 | 0.2-0.25 |

Maximum service temperature°C | 1350 | 1450 | 1550 |

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- According to my experience, two kinds of high alumina bricks from the index, there is a big difference between the content of AL2O3, a high aluminum brick in 75%, two grade high alumina bricks in 65%, so the content is not the same, also decided that the use of temperature difference, the difference is very big.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- Therefore, the choice and masonry of refractory bricks are of vital importance. If there is a brick kiln kiln off block process of reproduction, is now because of the use of refractory brick kiln material mostly three grade high alumina bricks. The content of AL2O3 is about 55%, of which the content of Fe2O3 is about 2%, which is weak, and the alkali corrosion resistance is a little worse. In a containing three grade high alumina bricks in the composition of AL2O3, Si2O3, and other elements also contain K, Na trace, were the most, thus causing the system of the low melting point is very low, even at 1400 DEG C has been liquid phase, and generate CaAL12O19 limestone and calcium feldspar etc.. Form corrosion loss. Therefore, a long time will cause the loss of block. On the one hand, it may be caused by construction.

- Q: What is the standard size of high alumina brick?

- Standard brick: 230 x 115 x 65; four points: 230 x 115 x 40; three points: 230 x 115 x 30; 150 x 120: Brick gable. Light weight brick 1 to 1.7 kilograms; heavy clay superscript brick weighs 3.75 kilograms; light 30 plates 0.79 kilograms; light 40 plates, 1.05 kilograms.

- Q: What are the specific raw materials for plastic pallets?

- There are two kinds of raw materials for plastic pallets: one is polypropylene (PP) and the other is polyethylene (HDPE).Plastic pallets for logistics storage: pp+pe material, recycled material 10%;Plastic trays for food trays: food grade PP, PE, pc;Polyethylene (HDPE) has excellent impact resistance and cold resistance, and it can resist environmental stress cracking. Excellent chemical stability, good oil resistance. Water absorption and tiny, low permeability, organic vapor transmission rate is larger. Electrical insulation is good, in all frequency range, dielectric properties are extremely excellent.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- RT3 series trolley type resistance furnace is a national standard energy-saving cycle type operation furnace. It has super energy-saving structure, adopts fiber structure and saves electricity 30%. Exclusive production of composite high aluminum nails group, car anti-collision sealing brick, automatic sealing trolley and furnace door, integrated rail, without the basic installation, placed on the ground floor can be used. Mainly used for high chromium, high manganese steel castings, ductile iron, roller, steel ball, 45 steel, stainless steel quenching, annealing, aging, and various mechanical parts heat treatment. Features: 1, no noise, no environmental pollution. 2, small heat storage, less heat loss. 3, high temperature control accuracy, furnace temperature uniformity. 4, a high degree of automation, simple. 5, PID programming can be used to set, fully automatic operation. 6, good sealing, long life, safe and reliable. Widely used in chemical, petroleum, food, metallurgy, machinery, light industry, electricity, ships, paper, mining, medicine, central heating and other industrial sectors. With the development of social productive forces, its application in various industries is more and more widespread. Two, pitannealingfurnace (for example: flange heat treatment furnace) use: the furnace for metal parts, such as ring of equipment heat treatment at rated temperature: the furnace is composed of furnace body and a movable furnace cover and control system.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: Difference between low creep high alumina brick and ordinary high alumina brick

- The emphasis is on the physical and chemical indexes of low creep and high alumina bricks. The physical and chemical indexes of the high alumina bricks are different, too. They are DRL-1550And LZ-75 perform GB GB/T2988-2012

- Q: What are the alloy wear resistance materials?

- KNMn19Cr2 (patent) high manganese alloy (ZGMn13Cr2MoRe), super high manganese alloy (ZGMn18Cr2MoRe); two: anti-wear chromium cast iron series: such as high, medium and low chromium alloy cast iron (Cr15MOZCu); three: wear resistant alloy steel series: such as, low and high carbon multi metal combined steel (such as ZG40SiMnCrMO and ZG35Cr2MoNiRe); four: ADI (ADI) series; five: all kinds of composite or gradient material and hard alloy materials, nano KN alloy (patent product): such as chromium carbide composite (Cr2C3+Q235), high-energy ion osmosized tungsten carbide materials (WCSP), high toughness of cemented carbide (YK25.6), KN999 nano alloy (Beijing Naimo patent) etc.;

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Halide. A few species, about 120 species, accounting for only 0.1% of the earth's crust. Most of them formed in the surface conditions, forming a salt mineral, containing less pigment ions, light color, low hardness, generally less than 3.5. Common mineral halite (NaCl), potassium (KCl), fluorite (CaF2) etc..

Send your message to us

High Alumina Lightweight Insulating Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords