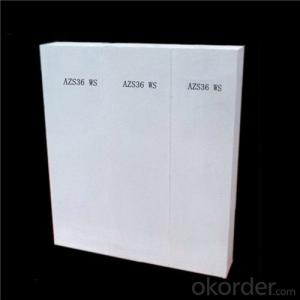

Textured Cinder Block

Textured Cinder Block Related Searches

Cinder Block Building Cinder Block Machine Cement Block Making Exterior Textured Wall Coatings Texture Coating Exterior Walls Hard Styrofoam Blocks Model Glass Block Recycled Brick Tiles Carbon Graphite Block Concrete Cap Blocks Corrugated Plastic Siding Block Moulding Machines Waterproof Concrete Blocks Staining Particle Board Waterproofing Concrete Block Walls Concrete Block Equipment Render Board Carbon Block Filtration Stacked Stone Exterior Siding Physical Therapy Foam Blocks Translucent Concrete Block Carbon Filters Bumper Materials Color Tile Concealed Spline Ceiling Cieling Panels Engineered Wood Fabricated Wall Panels Striped Tarpaulin Sticky LubricantTextured Cinder Block Supplier & Manufacturer from China

Textured Cinder Block, a unique and versatile construction material, is known for its distinctive appearance and durability. This product is widely used in various construction projects, including building walls, fences, and outdoor structures, due to its strength, affordability, and aesthetic appeal. It offers a cost-effective solution for both residential and commercial applications, providing a textured surface that can be easily painted or left as is, depending on the desired look. Okorder.com, a leading wholesale supplier, boasts a vast inventory of Textured Cinder Block, ensuring that customers have access to a reliable and consistent supply for their construction needs.Hot Products