High Temperature Thermal Insulation Texturized Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Texturized glass fiber cloth is a soft, flexible cloth manufactured from continuous filament texturized yarns. It is an ideal replacement for asbestos product used for thermal insulation and heat protection. It has low coefficient of thermal expansion and is suitable for temperature up to 550℃

Features: Excellent insulation property, High working temperature 550℃, Tight yarn construction, High strength and abrasive

Application: Insulation blanket, Insulation jacket, Further processing

PRICE: USD2 per square meter

UNIT: square meter

MOQ: 500square meters

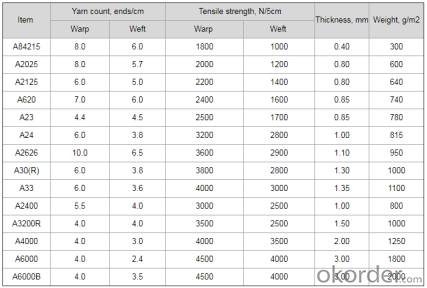

Weight: 300gsm-2000gsm

Thickness: 0.4mm-3mm

Roll length: customized

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Is fiberglass fabric resistant to oil and grease?

- Fiberglass fabric, in general, possesses resistance to oil and grease. Due to its exceptional chemical resistance properties, fiberglass demonstrates high resistance against a broad spectrum of oils and greases. This resistance stems from the non-reactive nature of fiberglass, preventing any degradation or damage to the fabric upon contact with oil and grease. Moreover, fiberglass fabric exhibits resistance to a multitude of other chemicals, such as acids, alkalis, and solvents, rendering it a versatile material suitable for various industries that require oil and grease resistance. Nonetheless, it is crucial to acknowledge that the degree of resistance may differ depending on the precise type and quality of fiberglass fabric employed. Consequently, it is always advisable to consult the manufacturer or supplier for precise information regarding the resistance capabilities of the specific fiberglass fabric under consideration.

- Q: Are fiberglass fabrics suitable for use in the agricultural industry?

- Indeed, fiberglass fabrics prove to be a fitting choice for implementation within the agricultural sector. The attributes associated with fiberglass fabrics render them optimal for usage in agricultural contexts. Primarily, fiberglass is renowned for its formidable strength and resilience, enabling it to brave the demanding conditions frequently encountered in agricultural environments. Consequently, fiberglass fabrics can be employed for a multitude of purposes, such as covering greenhouses, safeguarding crops against pests and inclement weather, and reinforcing agricultural machinery. Moreover, fiberglass fabrics possess resistance against chemicals and UV radiation, an indispensable quality within the agricultural industry due to the prevalence of fertilizers, pesticides, and exposure to sunlight. The chemical resistance guarantees that the fiberglass fabrics will remain intact and unaffected by these substances. Furthermore, UV resistance prevents the fabric from deteriorating or becoming brittle when exposed to sunlight for prolonged periods. Another noteworthy advantage of fiberglass fabrics in the agricultural realm is their fire resistance. This characteristic plays a crucial role in averting the fire's proliferation in the event of accidents or incidents involving flammable materials frequently found in agricultural settings. Furthermore, fiberglass fabrics are lightweight and effortless to handle, offering convenience for an array of applications within the agricultural sector. They can be effortlessly cut and customized to fit specific requirements, allowing for tailored solutions based on the preferences of farmers and agricultural workers. Ultimately, the combination of strength, durability, chemical resistance, UV resistance, fire resistance, and ease of handling renders fiberglass fabrics exceedingly suitable for implementation within the agricultural industry. They provide a dependable and versatile solution for diverse applications, contributing to the efficiency and productivity of agricultural operations.

- Q: How does fiberglass fabric perform in electromagnetic fields?

- Fiberglass fabric is a good choice for shielding against electromagnetic fields due to its non-conductive properties. It can effectively block or attenuate electromagnetic waves, providing excellent protection against electromagnetic interference.

- Q: What are the different fiberglass fabric coatings for chemical resistance?

- There are several different fiberglass fabric coatings available in the market that offer excellent chemical resistance. Some of the commonly used coatings include: 1. Polyvinyl Chloride (PVC) Coating: PVC coating provides good chemical resistance against a wide range of acids, alkalis, and solvents. It is commonly used in applications where protection against corrosive chemicals is required. 2. Polyurethane (PU) Coating: PU coating offers excellent resistance to abrasion, chemicals, and oils. It is often used in applications where the fabric needs to withstand harsh chemical environments. 3. Fluoropolymer Coating: Fluoropolymer coatings, such as PTFE (Polytetrafluoroethylene) and FEP (Fluorinated Ethylene Propylene), provide exceptional chemical resistance against corrosive chemicals, acids, and solvents. These coatings are widely used in industries like chemical processing, pharmaceuticals, and food processing. 4. Silicone Coating: Silicone coating offers good resistance to chemicals, oils, and extreme temperatures. It is commonly used in applications where both chemical resistance and high-temperature resistance are required. 5. Neoprene Coating: Neoprene coating provides excellent resistance to a wide range of chemicals, oils, and solvents. It is commonly used in applications where the fabric needs to withstand exposure to aggressive chemicals. It is important to note that the choice of coating depends on the specific chemical environment and the level of resistance required. It is recommended to consult with a technical expert or coating manufacturer to determine the most suitable fiberglass fabric coating for a particular chemical resistance application.

- Q: How is fiberglass fabric used in the production of protective gloves?

- Fiberglass fabric is used in the production of protective gloves as it provides excellent heat resistance and insulation properties. It is often used as a lining material in gloves to protect the wearer from extreme temperatures and potential burns. The fiberglass fabric acts as a barrier, preventing heat transfer and ensuring the safety of the user. Additionally, fiberglass fabric is lightweight and flexible, allowing for comfortable and dexterous glove designs.

- Q: What is the cost range for fiberglass fabrics?

- The price range of fiberglass fabrics can differ based on a variety of factors, including the fabric's quality, weight, and width, as well as the supplier and any additional features or treatments applied to it. On average, fiberglass fabrics typically cost between $5 and $20 per yard. However, certain high-end or specialized fiberglass fabrics that possess specific properties or finishes can have higher price tags, sometimes exceeding $50 per yard or even more. It is important to remember that these prices are only approximate and may vary due to market conditions and individual suppliers. Furthermore, bulk orders or wholesale purchases might offer discounts, so it is advisable to directly contact suppliers for accurate pricing information.

- Q: Can fiberglass fabrics be used for insulation in aerospace components?

- Yes, fiberglass fabrics can be used for insulation in aerospace components. Fiberglass is known for its excellent thermal insulation properties and is widely used in various industries, including aerospace. It is lightweight, flexible, and can withstand high temperatures, making it suitable for insulating different aerospace components such as engine compartments, fuel tanks, and exhaust systems. Additionally, fiberglass fabrics are resistant to chemicals, moisture, and fire, which further enhance their suitability for aerospace insulation applications.

- Q: What are the different fiberglass fabric weaves for flexibility?

- Flexibility can be achieved through various fiberglass fabric weaves. Among the commonly used weaves are plain weave, twill weave, satin weave, and leno weave. Plain weave is the most basic and straightforward weave, where each warp thread goes over and under each weft thread in a grid-like pattern. It offers decent flexibility and is often used for lightweight purposes. Twill weave, on the other hand, creates a diagonal pattern by interlacing warp and weft threads. This weave provides greater flexibility and strength compared to plain weave, making it suitable for applications that require durability. Satin weave is renowned for its smooth and shiny appearance. With long floats and fewer interlacements between warp and weft threads, satin weave offers excellent flexibility and drapability. It is a popular choice for applications that demand a soft and flexible material. Leno weave is a unique pattern where warp threads twist around adjacent weft threads, creating an open and flexible mesh-like structure. This weave provides high flexibility and breathability, making it ideal for filtration and reinforcement applications. Ultimately, the choice of fiberglass fabric weave for flexibility depends on the specific requirements of the application. Each weave offers different levels of flexibility, strength, and appearance, enabling manufacturers to choose the most suitable option for their particular needs.

- Q: Is fiberglass fabric suitable for use in medical implants?

- Medical implants necessitate biocompatible materials, which do not induce any adverse reactions or harm to the human body. While fiberglass fabric possesses strength, durability, and resistance against high temperatures, its usage in medical implants is infrequent due to its potential to trigger inflammatory reactions, cause tissue damage, or generate toxic effects. Instead, medical implants frequently incorporate materials like titanium, stainless steel, or biocompatible polymers such as polyethylene or polyurethane. These materials have undergone extensive testing to guarantee their safety and compatibility with the human body. Additionally, they are engineered with specific properties that facilitate integration with surrounding tissues, stimulate healing, and minimize the risk of complications. To conclude, fiberglass fabric is unsuitable for medical implants because of its lack of biocompatibility. It is crucial for medical implants to be composed of materials that are safe, non-toxic, and well-tolerated by the body, ensuring successful outcomes and patient safety.

- Q: Can fiberglass fabric be used for insulation in underground structures?

- Indeed, insulation in underground structures can be achieved by utilizing fiberglass fabric. This fabric is highly favored for its exceptional thermal characteristics and ability to withstand moisture. It is widely employed in numerous applications, notably in underground structures like basements, tunnels, and underground storage facilities. Typically, the fabric is positioned as a layer between the structure's walls or ceiling and its interior finish, serving as a protective barrier that curbs heat loss or gain and promotes a pleasant temperature within the structure. Moreover, fiberglass fabric is renowned for its lightweight nature, flexibility, and simplicity of installation, rendering it a convenient choice for insulating subterranean spaces.

Send your message to us

High Temperature Thermal Insulation Texturized Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords