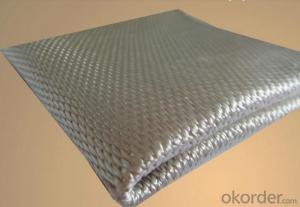

High Temperature Insulation Kevlar Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRICE: USD10 per square meter

UNIT: square meter

MOQ: 500 square meter

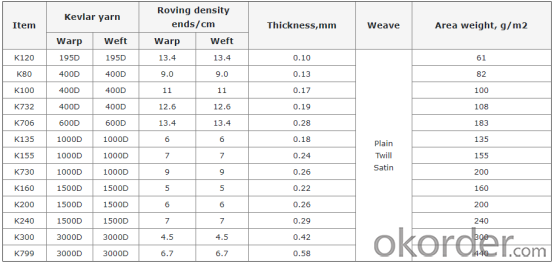

Weight: 50-460gsm

Width: 1-1.8m

Roll length: 100 meters or customized

Weave Type:plain, twill

Material: fiberglass

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Rolls packed In cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

Description: Kevlar® fabric is made by kevlar continuous filament fiber yarn. The kevlar is a famous brand of Dupont. Currently, there are available with K29, K49, part of K129 fabrics.

For economic purpose, we also supply China local supplier's para aramid fiber yarn.

Application: High strength lamination; Bulletproof; Fireproof

- Q: What is the chemical resistance of fiberglass fabric?

- Fiberglass fabric exhibits excellent chemical resistance due to its composition and structure. It is made of woven strands of glass fibers that are highly resistant to most chemicals, including acids, bases, solvents, and oils. This resistance is primarily attributed to the glass fibers themselves, as glass is inherently inert and does not react with most chemicals. Additionally, fiberglass fabric is often coated or treated with various substances to enhance its chemical resistance further. These coatings or treatments can provide additional protection against specific chemicals or environments, making fiberglass fabric suitable for a wide range of applications. However, it is important to note that while fiberglass fabric is generally resistant to chemicals, there may still be certain exceptions. Some highly corrosive or reactive chemicals may still attack the fabric, causing degradation or damage over time. Therefore, it is always recommended to consult the specific chemical resistance chart or manufacturer's recommendations for the particular fiberglass fabric being used to ensure its compatibility with the intended chemical environment.

- Q: Can fiberglass fabric be used for insulation in clean rooms?

- Yes, fiberglass fabric can be used for insulation in clean rooms. It is a commonly used material in clean room environments due to its excellent thermal insulation properties and resistance to contamination.

- Q: How does fiberglass fabric perform in flexibility?

- Fiberglass fabric is known for its excellent flexibility. It can be easily bent, twisted, or molded into various shapes without losing its structural integrity. This makes it a versatile material that can be used in a wide range of applications, from automotive and aerospace industries to construction and recreation.

- Q: Is fiberglass fabric suitable for high-stress applications?

- Yes, fiberglass fabric is suitable for high-stress applications. It has excellent strength, durability, and resistance to heat, chemicals, and abrasion, making it a reliable choice for industries such as aerospace, automotive, and construction, where high-stress conditions are common. Its lightweight nature and flexibility further enhance its suitability for such applications.

- Q: What are the environmental considerations of using fiberglass fabric?

- There are several environmental considerations associated with using fiberglass fabric. Firstly, the production of fiberglass fabric involves the extraction of raw materials such as silica sand, limestone, and soda ash, which can have negative impacts on ecosystems and contribute to habitat destruction. Additionally, the manufacturing process itself requires a significant amount of energy, which often comes from non-renewable sources and can contribute to greenhouse gas emissions and air pollution. Furthermore, fiberglass fabric is not biodegradable and can persist in the environment for a long time if not properly disposed of. This can lead to accumulation in landfills, increasing waste generation and occupying valuable space. Moreover, the use of fiberglass fabric in certain applications, such as insulation or boat building, may release microscopic glass fibers into the air. Inhalation of these fibers can pose health risks, including respiratory issues and lung damage, for workers involved in the production or installation of fiberglass products. On the positive side, fiberglass fabric is highly durable and long-lasting, which can reduce the need for frequent replacements and minimize waste. It is also resistant to moisture, chemicals, and fire, which can contribute to the safety and longevity of structures or products in which it is used. To mitigate the environmental impacts of using fiberglass fabric, it is essential to consider sustainable alternatives and practices. This could include using recycled fiberglass materials, reducing energy consumption during production, improving waste management and recycling programs, and promoting proper safety measures to protect workers from the potential health hazards associated with fiberglass. Additionally, exploring alternative materials that are more eco-friendly and have a lower environmental footprint could also be considered.

- Q: Is fiberglass fabric resistant to rodents?

- Yes, fiberglass fabric is generally resistant to rodents. Its composition and texture make it unattractive and difficult for rodents to chew through or nest in.

- Q: How is fiberglass fabric recycled?

- The process of recycling fiberglass fabric involves multiple steps and utilizes different techniques and technologies to convert used or waste fiberglass materials into new products. Typically, the recycling process consists of the following steps: 1. Waste Collection: Initially, the waste materials of fiberglass fabric are gathered. This can be accomplished through various methods, such as waste management systems, industrial recycling programs, or specialized collection centers. 2. Sorting: Once collected, the fiberglass fabrics are sorted based on their type, color, and condition. This sorting process assists in determining the suitable recycling methods and potential applications for the recycled material. 3. Shredding: Subsequently, the sorted fiberglass fabrics are shredded into smaller pieces or fibers. This fragmentation facilitates the handling and processing of the material in subsequent stages. 4. Cleaning: The shredded fiberglass undergoes a thorough cleaning process to eliminate any contaminants or impurities. Typically, this involves washing the material with water and detergents to ensure it is free from any residues. 5. Resizing: After cleaning, the fiberglass fibers may undergo a resizing process to achieve a consistent length or size. This step is crucial for ensuring uniformity in the final product. 6. Melting: The resized fiberglass fibers are then subjected to high temperatures, causing them to melt. This melting or liquefying process transforms the fibers into a molten state, making them easier to manipulate and shape. 7. Reinforcement: Once melted, the fiberglass can be used as a reinforcing material. It is commonly combined with resins like polyester or epoxy to create composite materials used in various industries, including construction, automotive, and aerospace. 8. Molding: The molten mixture of fiberglass and resin is molded into desired shapes or forms using techniques like injection molding, compression molding, or pultrusion. This enables the recycled fiberglass to be transformed into new products, such as insulation, panels, pipes, or even sporting goods. 9. Final Processing: After molding, the newly formed fiberglass products may undergo additional processes, such as curing, cooling, or surface finishing, to enhance their properties and ensure their quality. 10. Market Distribution: Finally, the recycled fiberglass products are packaged and distributed to the market, where they can be purchased and utilized by various industries and consumers. Overall, the recycling of fiberglass fabric is a complex process that aims to repurpose and transform waste materials into valuable products, reducing the environmental impact of fiberglass waste and promoting a more sustainable approach to manufacturing and consumption.

- Q: Is non-woven fabric and fiberglass all the same?

- Just do it in nonwoven production line products referred to as non-woven fabrics, like eating rice, glutinous rice, rice, black rice, red rice called rice

- Q: Can fiberglass fabric be used for making heat shields?

- Yes, fiberglass fabric can be used for making heat shields. Fiberglass fabric is known for its excellent heat resistance properties, making it an ideal material for heat shielding applications. It can withstand high temperatures without melting or deforming, providing a protective barrier against heat transfer. Additionally, fiberglass fabric is lightweight, flexible, and has good insulation properties, making it suitable for various heat shield applications, such as in automotive, aerospace, and industrial settings.

- Q: Can fiberglass fabric be used for making stage curtains?

- Yes, fiberglass fabric can be used for making stage curtains. Fiberglass fabric is a versatile material that offers several benefits for stage curtains. Firstly, it is lightweight and durable, making it easy to handle and resistant to wear and tear. This is important for stage curtains as they need to withstand frequent opening and closing during performances. Additionally, fiberglass fabric is flame retardant, ensuring the safety of the stage and performers. It also provides excellent acoustic properties, helping to absorb sound and improve the acoustics in the theater. Moreover, fiberglass fabric is available in a variety of colors and can be easily painted or printed on, allowing for customization and artistic expression. Overall, fiberglass fabric is a suitable choice for making stage curtains due to its durability, fire resistance, acoustic properties, and aesthetic flexibility.

Send your message to us

High Temperature Insulation Kevlar Fabric

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords